Until now, researchers, metrologists, and engineers often have had to choose between accurate metrology and visually compelling imaging-based measurements. You no longer have to make that choice. Bruker’s Contour Elite™ 3D optical microscopes combine the ContourGT® platform’s proven, industryleading metrology and Vision64® analysis software with exceptional new highfidelity imaging capabilities. Contour Elite delivers the highspeed operation, accuracy, and repeatability that toplevel R&D and production requires, and adds the imaging and display advantages commonly associated with confocal microscopy.

Reliable Measurement Data Enhanced by High-Fidelity Imaging

Many industries manufacture products that have critical performance requirements, where it is absolutely essential that the products are exactly right every time. In the medical industries, such products include medical implants, such as intraocular lenses, hip or knee replacement joints, and heart stents. Similarly, the automotive and aerospace industries demand the highest performing parts and assemblies to ensure safety or mission success. Bruker’s surface characterization systems are the instruments of choice in industries such as these because repeatable, quantitative metrology data is paramount in reaching certainty about quality and performance.

Bruker’s 3D optical technology has a long history featuring the best instrument designs, most advanced engineering, and the highest quality control—all imperatives for performance-critical manufacturing and advanced research. Now, Contour Elite systems offer the unprecedented combination of exacting metrology, superb data analysis, and high-fidelity imaging in a single 3D microscope platform.

Quantitative, Repeatable, Surface Data for Informed R&D and QA/QC Decisions

Contour Elite systems are an advancement of Bruker’s industry-leading ContourGT platform, which is known for its robust, gauge-capable metrology. Proven, stable hardware design and manufacturing ensure high vibration tolerance for enhanced reliability and measurement repeatability, even in noisy production environments.

Industry’s Best Available Lateral and Vertical Resolution in a 3D Optical Microscope

The Contour Elite systems boast the best combined lateral and vertical resolution over the industry’s largest field of view, with a sub-nanometer to greater than 10 millimeters vertical range. They include the R&D 100 Award-winning AcuityXR® measurement technology, which provides the best available lateral resolution in an industrial 3D optical microscope, and the ability to break the diffraction limit. AcuityXR reduces blur caused by optical elements and, for narrow features, it offers an enhanced capability to quantify edge variations making process control possible even on the smallest structures. In addition, the systems can utilize a megapixel camera that increases X-Y spatial resolution. A large field of view and objective magnifications from 1X to 115X enable characterization of an extremely wide range of surface shapes and textures. And the capability for precise stitching enables users to seamlessly synthesize thousands of individual datasets into one contiguous image with ease. Simply navigate to the corners of the desired image, mouse-click to mark the locations, and the software does the rest.

Simple and Intuitive Operation for Exceptional Ease of Use

Contour Elite’s streamlined user interface maximizes user efficiency and simplifies measurements and analyses. Contour Elite is not only simple to use, it is also the most comprehensive and fully featured 3D surface metrology platform available today.

Intuitive, User-Friendly Interface for Simplified Characterization and Analysis

The Vision64 Measurement Setup window has an easy “pull-down” menu to select measurement type and magnification. The stage is easily positioned using the Instrument Control window or joystick, and the new Easy Measure tab’s single-button wizard enables even novice users to collect quality data within seconds. Simple illumination control optimizes lighting to better view sample features in the Live-Video window. Plus, a height map or a high-fidelity image is displayed in real-time as measurement data is produced, making the entire measurement process extremely intuitive.

The system carries this same ease-of-use functionality through a vast suite of analysis routines. The Data Analysis window provides access to the most common plot objects with the click of a button. Contour Elite makes it easy to customize plots, combine plot types and create reports, or add text and graphics. Data parameter tables are completely configurable and sortable in seconds. The Active Gallery displays all open datasets, and, when one is selected, activates its Data Visualization window and corresponding workflow activities.

For example, the Data Analyzer serves as an intuitive visual workflow tree to define an analysis, and the Analysis Toolbox offers a broad selection of ISO-compliant analyses and filters that can be combined with masking and shape removal for extraction of roughness, waviness, or form. Comprehensive surface measurements incorporate key attribute calculations and yield reliable and accurate data across a wide range of applications.

High-Fidelity Imaging to See What You Measure

Equally critical to collecting accurate data is communicating the findings. The addition of high-fidelity grayscale and color imaging, with exclusive side illumination and advanced algorithms, gives Contour Elite users access to additional perspectives not possible on systems that provide metrology alone, as well as the capability to provide recognizable surface feature details for reporting.

True Color Imaging, Color Segmentation, and Metrology Seamlessly Combined

Combining high-end metrology with the ability to see, recognize, and display what was measured is of great importance, not only for understanding the data, but also for communicating the results. Accurate metrology data and crisp surface images give users the complete surface characterization story.

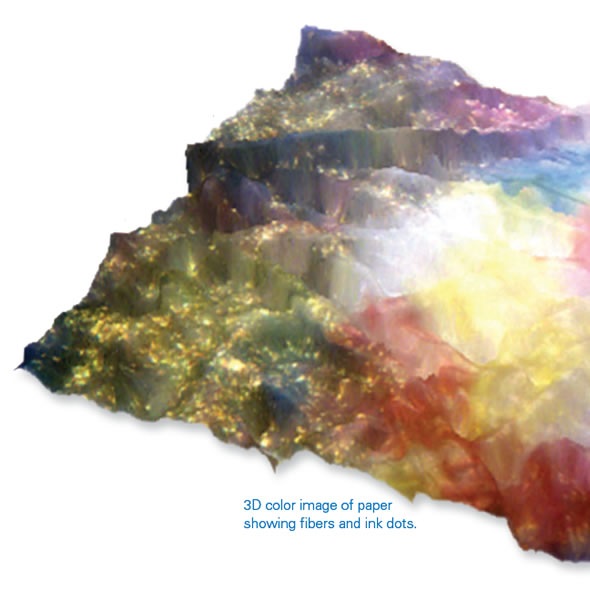

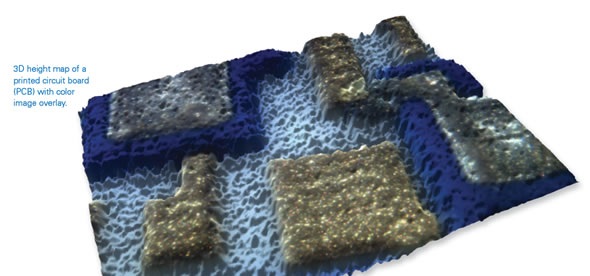

Color and Grayscale Imaging to Reveal Previously Hidden Microscopic Details

Contour Elite’s high-fidelity imaging reveals specific surface details that otherwise would be difficult or impossible to see. This new capability enables users to segment data based on color or grayscale information to rapidly select areas of interest and collect critical metrology data from these specific regions. A data display of the color or grayscale information on a 3D height map, which essentially builds a vivid graphic representation of a magnified zoom into the part, gives the user the ability to actually see the sample along with its 3D topography, leading to better problem solving in engineered surface applications.

Faster Solutions to Complex Research and Production Challenges

Contour Elite 3D optical microscopes feature an intuitive visual workflow, extensive usercustomization features, automated functions, highly accurate measurement capabilities, and high-fidelity imaging to provide the fastest, most comprehensive data collection and analysis available for a vast range of research and production applications. Built on three decades of proprietary Wyko® white light interferometric (WLI) hardware and software technology innovation, Contour Elite systems deliver industry-leading surface characterization, pushing Contour capabilities to new heights of functionality by tightly integrating advanced 3D optical metrology technology, high-fidelity imaging, patent-pending illumination design, and proprietary software algorithms for data processing, analysis and visualization.

Rapid, Non-Destructive Imaging with the Fastest Time to Data

Contour Elite microscopes are non-contact systems with large stages that leave your samples or parts intact and undamaged. Our patented WLI technology acquires height data with sub-nanometer precision that is independent of the magnification used. This means that, even when sampling over a million data points in a millimeters-squared image area, a user is able to collect high-resolution height data—all within a few seconds.

Contour Elite’s Automation Scripting has been designed to further capitalize on this rapid data acquisition. The programmable X-Y scatter automation enables fast, easy measurement on samples with irregularly spaced areas of interest. For more specialized applications, scripts can be quickly set up and saved as “recipes” for use on demand. Plus, a variety of automation routines and sample traversal patterns are available to give users an easy way to customize the systems to their particular requirements.

Most Advanced, Production-Ready Automation

To further enhance these capabilities for manufacturing, an optional Advanced Production Interface adapts Contour Elite systems to automated processes or production environments, providing tools to customize process workflows, automate mapping, and load measurement recipes. Software prompts and password-protected entries eliminate human error and support robust and accurate measurement performance from operator to operator.

Flexible Staging and Fixturing to Fit Your Application

The Contour Elite microscopes are available with an automated 150-millimeter (6-inch) stage or a 300-millimeter (12-inch) stage. For cylindrical samples there is also an option for a roller stage that can be used to rotate the parts to acquire surface data—either at specific sites or by utilizing cylindrical stitching.

A tip/tilt cradle angles the optics, not the sample, so the sample always stays in focus and within the measurement field of view. An optional motorized turret is available that accommodates up to five objectives, with magnification from 0.5X to 230X. The turret design ensures that measurement features stay in focus and centered, even when switching objectives or magnifications.

Additional customization and capabilities are available through optional software packages, such as Optical Analysis, SureVision, and automated MATLAB scripting. Whatever your application, Contour Elite allows you to select the optimal surface characterization solution.