When it comes to preventing wire bonding failures, Henniker Plasma - a leading manufacturer of plasma surface treatment equipment - has the expertise to advise on the latest and most reliable solutions on the market.

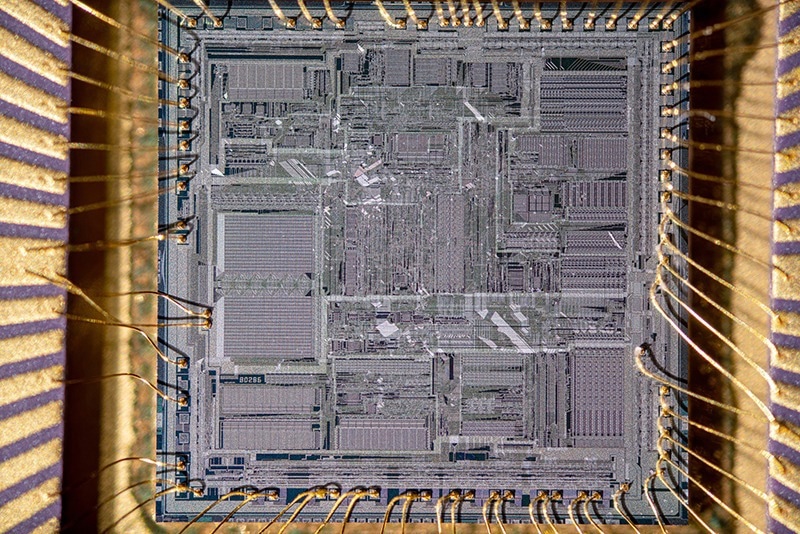

Wire bonding is a technique usually applied when making electrical interconnections between semiconductors, integrated circuits, and silicon chips using fine wires. These wires are extremely delicate and carry key information to the electronic chip.

If they fail, the effectiveness of their performance and the interconnections between the electronic parts perform become compromised. For a majority of semiconductor and electronics manufacturers, wire bond failure is a significant concern.

Wire-bonded silicon chip. Image Credit: Henniker Plasma

The presence of contamination is a common cause of wire bonding failure

Bond pad contamination

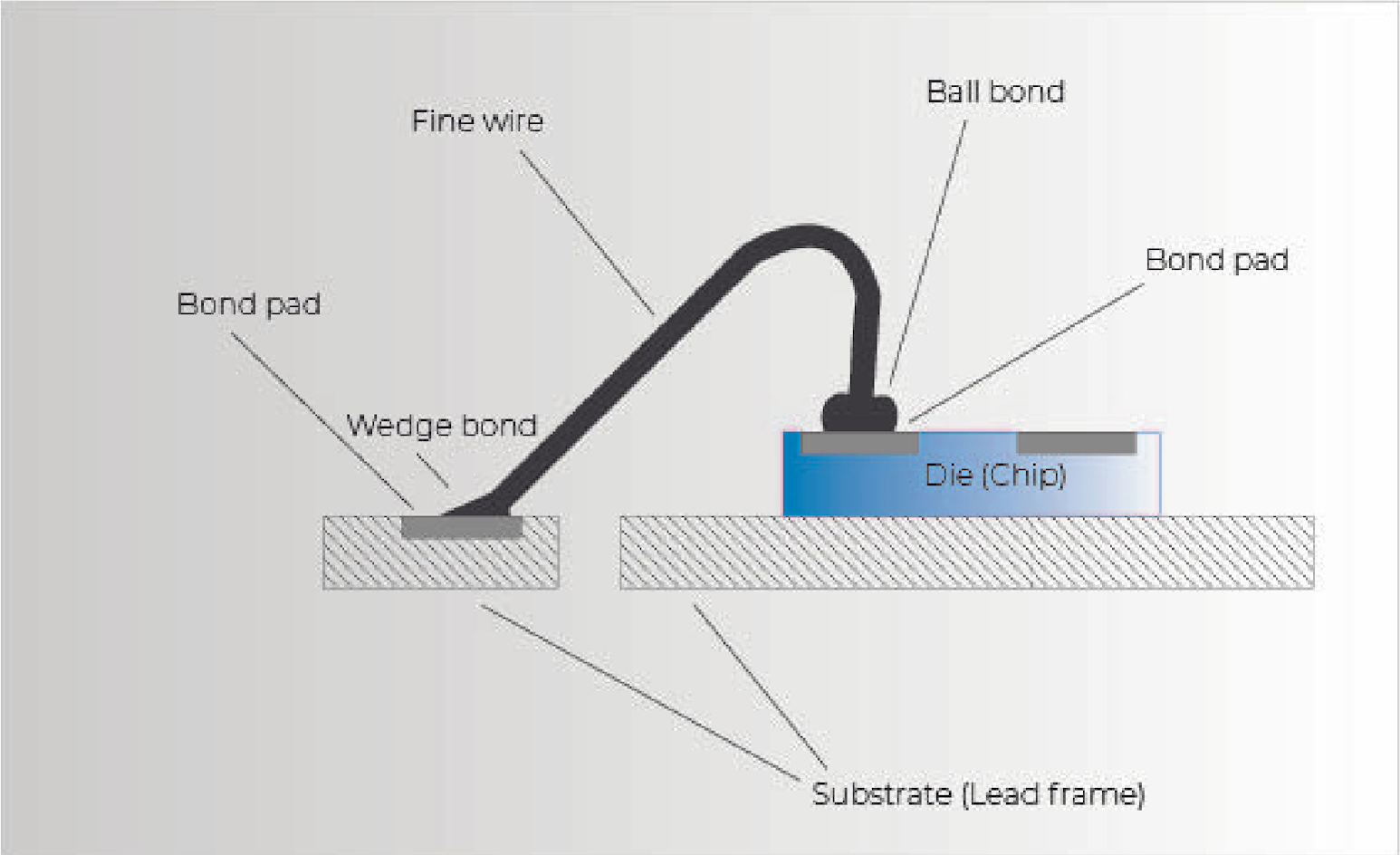

Wire bond failure tends to happen when the fine wire bonds cannot form an effective connection with a bond pad. Halogen and silicone contamination may lead to corrosion and hinder proper adhesion. The accumulation of corrosion by-products can also become damaging, particularly if they are present at the time of bonding.

Diagram of typical wire bond. Image Credit: Henniker Plasma

Lead frame contamination

The lead frames used when assembling semiconductor devices must be totally contaminant free. The presence of any contaminant on the contact surfaces of lead frames can have a negative impact on quality leading to insufficient bond formation, which in turn prevents good adhesion, leading to total failure of the entire integrated circuit.

Plasma cleaning solutions

When it comes to efficiently removing organic contaminants and thin oxide layers under high throughput conditions, plasma cleaning is viewed as the industry standard for wire bonding as it is quick and efficient, as well as boosting reproducibly, which improves yield and reduces bond failures.

Henniker Plasma is the UK’s primary manufacturer of plasma treatment systems for cleaning and surface activation, which improves adhesion and functional nano-scale coatings. Henniker’s market-leading systems are renowned for their reliability and delivery of ultra-fine surface preparation.

The Henniker Plasma range. Image Credit: Henniker Plasma

Plasma cleaning process

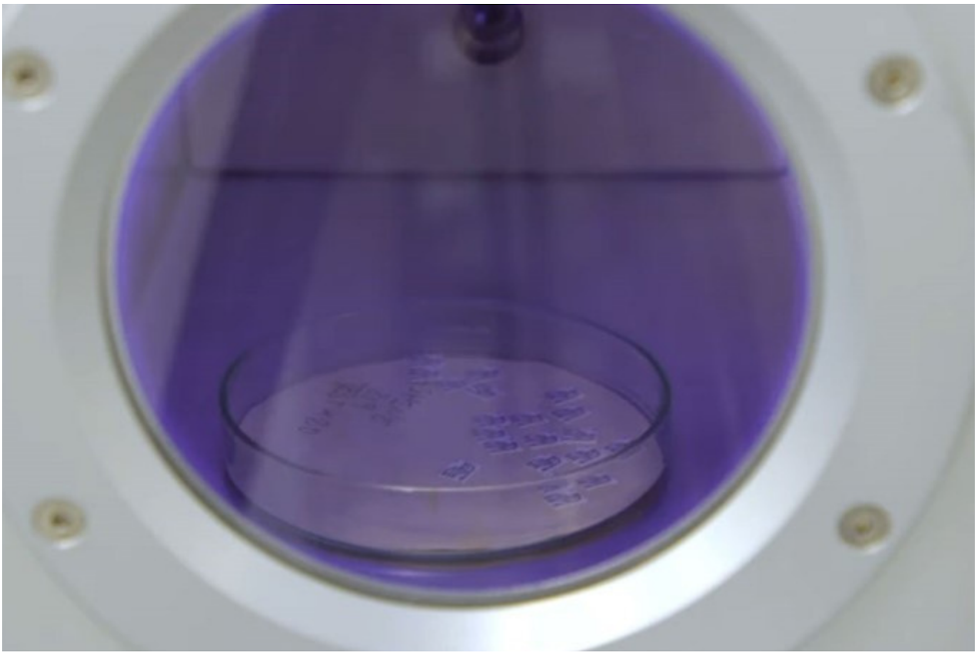

Plasma cleaning can be executed as an in-line solution, e.g., before the encapsulation process or when introduced as a batch processing step, with customized frame loading configurations.

Batch processing necessitates that parts are loaded into a plasma chamber. The process is effective and fast; the entire treatment can be completed in less than five minutes.

Batch processing in a Henniker HPT-300 system. Image Credit: Henniker Plasma

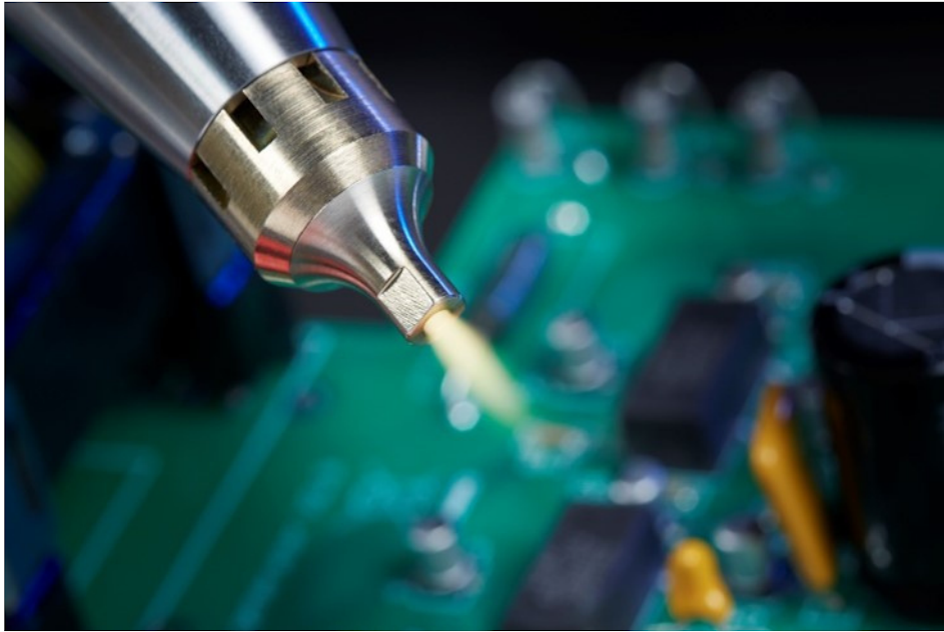

Conversely, an atmospheric plasma torch system, such as Henniker’s Cirrus unit, can be incorporated into an in-line assembly and placed under the complete control of the host system to ensure localized bond-pad treatment is achieved.

Henniker atmospheric system 'Cirrus'. Image Credit: Henniker Plasma

Plasma cleaning uses argon, hydrogen, and oxygen, or a mixture of these gases. Combinations of these gases can be used in almost all cases. However, there are considerations to be made, as oxygen will likely dullen leadframes, and the presence of argon can lead to the re-deposition of metal particles. Moreover, some safety issues may also arise when using hydrogen.

Henniker has designed a simple, low-cost alternative that effectively removes contamination and reduces oxide layers without any potential drawbacks utilizing a method based on plasmas that have been generated using water vapor.

50:50 Water vapor plasma treated coin. Image Credit: Henniker Plasma

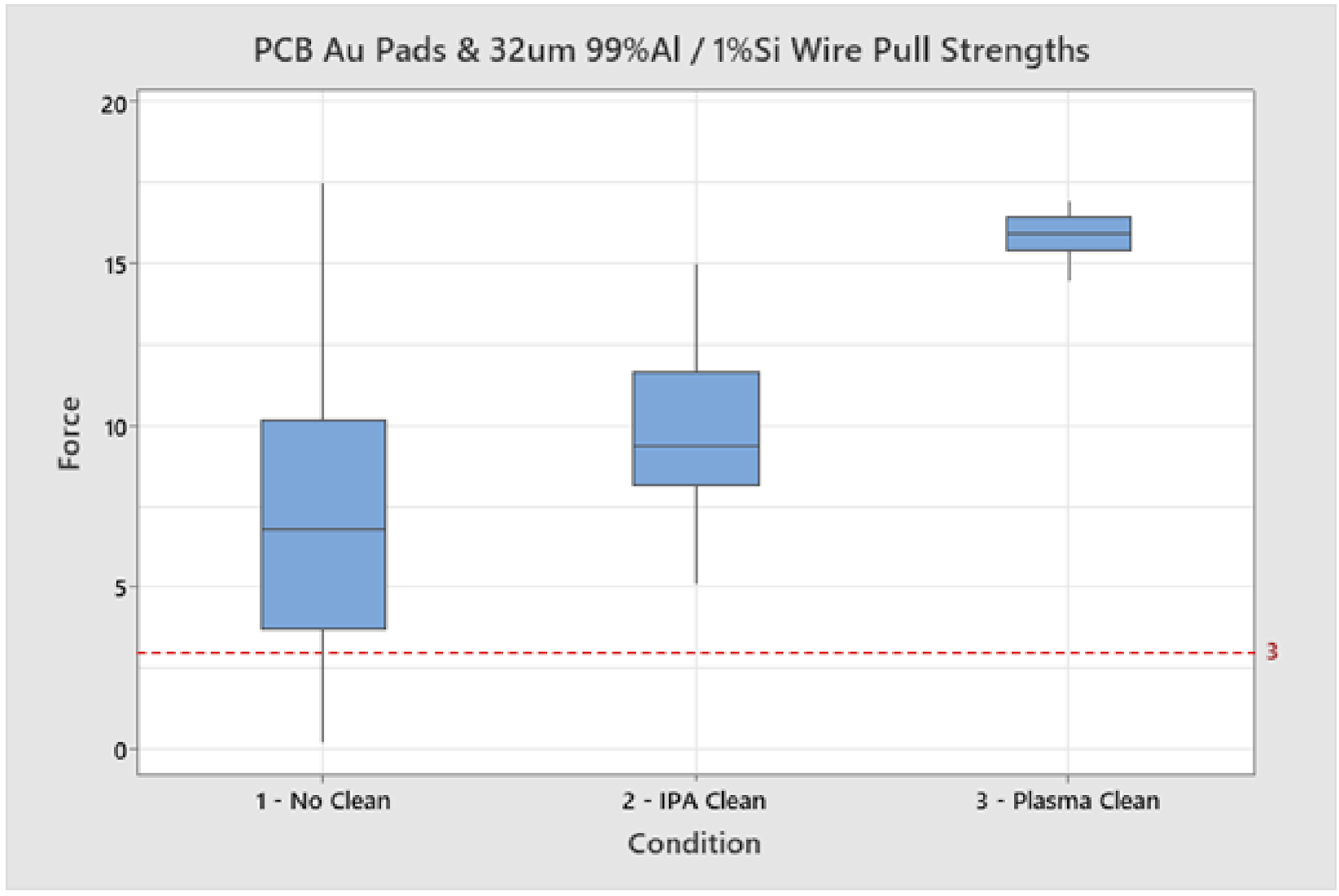

Wire bond test results

Once plasma treatment has been successfully applied, wire bond strength is assessed using both Destructive Pull Tests (OPTS) and Non-Destructive Pull Tests (NDPTs).

Comparison of the effect of a different cleaning methods on the pull strength of wire bonds using Henniker's HPT-300 Plasma System. Image Credit: Henniker Plasma

The results shown above offer a comparison of pull strengths for a variety of cleaning methods and demonstrate both the bond improvement and the variability reduction that can be accomplished when plasma cleaning is applied.

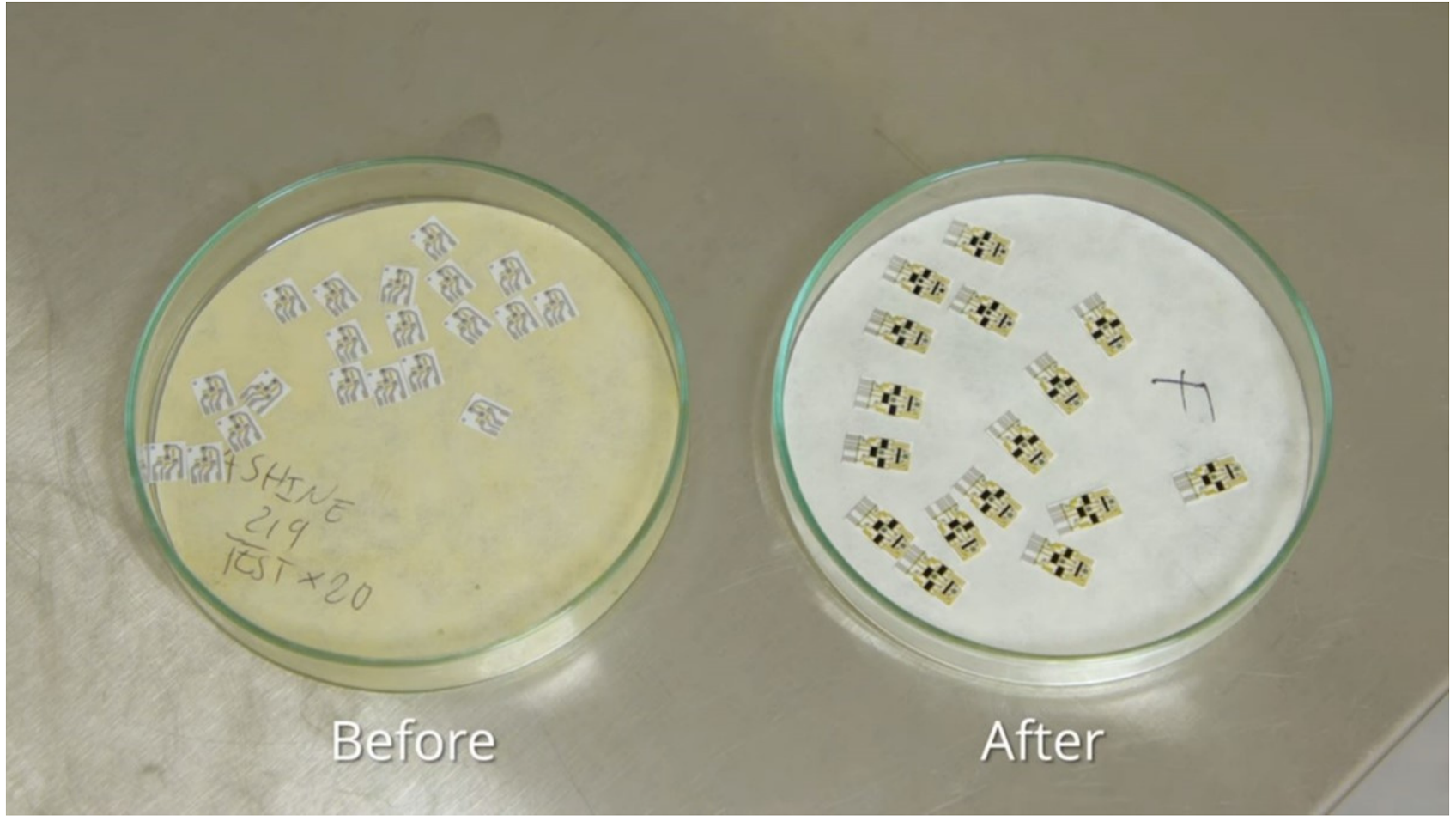

Real-world application - Solid State Supplies

For a number of years, Henniker’s plasma systems have been in operation at the UK’s ‘Solid State Supplies’ manufacturing facility. Solid State Supplies deliver end-to-end solutions for optoelectronic and display assemblies.

Before and after plasma treatment. Image Credit: Henniker Plasma

“Wire bond failure rates have been extremely low while the Henniker Plasma cleaner has been in operation at Solid State. Operation of the machines has been trouble-free with excellent reliability.”

About Henniker Plasma

Henniker – Passionate about Plasma®

We are an experienced, dynamic and expanding company already established as a leading UK manufacturer of plasma treatment systems for cleaning, activation and coating.

Our success is built around an exceptional body of knowledge and expertise, backed by highly trained and dedicated staff who understand your application in considerable detail. Our standard configurations cover most applications but we understand too that no two samples or surfaces are the same. That’s why, uniquely, we offer a wide range of options that allow us to customise any standard system for your exact requirement.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.