The Class 2 Biological Safety Cabinet makes use of a ventilated enclosure, which has been developed explicitly for sterile material handling and sensitive processes where biological samples are in use. These processes require a safe work zone to ensure the safety of the user, the sample, and the surrounding environment.

All Class 2 Safety Cabinets are independently type tested and approved to meet BSEN 12469:2000 standards set by the Health Protection Agency at Porton Down - the UK’s leading authority on BioSafety Cabinets.

- Creating clean environments: The H14 HEPA filters, which are 99.97% efficient at 0.3 um, ensure advanced contamination protection and an ISO Class 4 Clean Environment.

- Health protection agency tested: Independently type tested and approved to meet BSEN 12469:2000 standards set by the UK’s leading authority on BioSafety Cabinets, the Health Protection Agency.

- Tailored to users' application: Users can choose between an A2 (Recirculating) or C1 (Hazardous Chemical Use) Model, each of which is available in three widths (800 mm, 1200 mm, 1800 mm) to match users’ applications.

- Automatic ECO mode: Power output reduced, lighting and display deactivated, and fan speed reduced to 50% following a period of operator inactivity.

Guaranteed product, personnel, and environmental protection

The Class 2 Biological Safety Cabinets keep any team safe while helping to eliminate any hazardous materials.

Manufactured to the highest quality standards, the advanced biosafety solution has been fitted with H14 HEPA Filters to make an ISO Class 4 Clean Environment. It also features energy-efficient LED lighting, controlled airflow, an intuitive control system, and UV sterilization functionality.

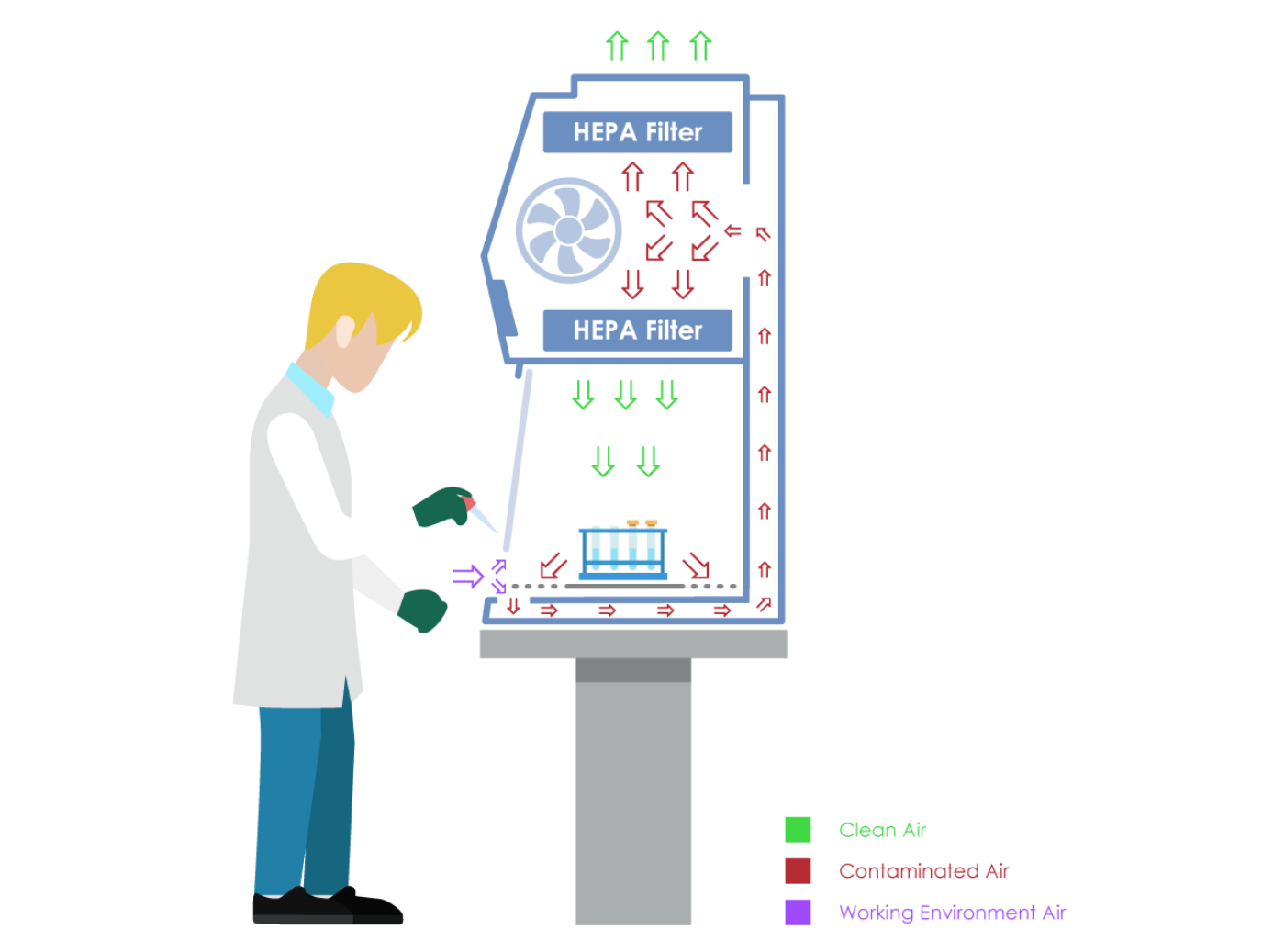

The Class 2 Microbiological Safety Cabinet makes use of a flow of air drawn through the front aperture into the cabinet. This inward airflow (personnel protection) prevents aerosols generated at the time of the microbiological processes from escaping via the front opening.

A vertical downward HEPA-filtered laminar airflow (product protection) comes unidirectionally out of the cabinet's front face, creating an air curtain while continually flushing the enclosure of airborne particles and ensuring the working sample is protected from contamination.

The contaminated air subsequently makes its way into a HEPA filter system (environmental protection) before it is safely exhausted from the enclosure.

Class 2 Biological Safety Cabinets are ideal for teams working with microbiological agents recognized to Biosafety Levels 1, 2, 3, or 4.

Product specification

Source: Monmouth Scientific Limited

| Model |

MSC 800 |

MSC 1200 |

MSC 1800 |

External

(W x D x H) |

800 mm x 750 mm

x 1351 mm* |

1200 mm x 750 mm

x 1351 mm* |

1800 mm x 750 mm

x 1351 mm* |

Working

(W x D x H) |

707 mm x 500 mm

x 690 mm |

1107 mm x 500 mm

x 690 mm |

1707 mm x 500 mm

x 690 mm |

Air Cleanliness

& Filter |

>ISO Class 4 (Class 10) | H14 HEPA Filter – 99.97% efficient at 0.3 um |

Downflow

Velocity |

492 m3/hour @

0.38m/second |

759 m3/hour @

0.38 m/second |

1158 m3/hour @

0.30 m/second |

Inflow

Velocity |

390 m3/hour @

0.77m/second |

612 m3/hour @

0.77 m/second |

945 m3/hour @

0.77 m/second |

Aperture

Height |

200 mm |

| Power |

150 watts |

250 watts |

320 watts |

| Weight |

110 kg |

165 kg |

230 kg |

| Sound |

<62 dB |

<64 dB |

<63 dB |

*Optional HEPA Outlet +46 mm/Optional Carbon Outlet +55 mm/Optional Double HEPA & Carbon Outlet +129 mm Height.

Key features and benefits

Researchers and laboratories across the globe trust Monmouth Scientific’s Class 2 Biological Safety Cabinets, particularly those working in cell culture, clinical, pharmaceutical, and microbiological applications.

Cabinet specifications

- Models: MSC800–800 mm, MSC1200–1200 mm, MSC1800–1800 mm

- Polyester Coated Zintec Mild Steel with Toughened Glass Glazing Panels

- A2 (Recirculating) and C1 (Chemical Use) and Carbon Filtered Exhaust Cabinet Specs Available

Fields of application

- Food industry

- Hospital and pharmacy

- Laboratories and research

- Medical technology

- Biotec and life sciences

UV chamber disinfection

Pre-programmed start and finish guarantees efficient and total disinfection.

High-quality filters

High-quality HEPA filters are 99.997% efficient at 0.3 microns, ensuring an ISO Class 4 Clean Environment.

Eco mode

PIR Sensors guarantee efficient energy consumption by keeping the cabinet in Eco Mode following a period of operator inactivity.

- Cabinet Power Output decreased

- Fan Speed decreased to 50%

- LED Lighting and Visionaire® Display Deactivated

Sectional stainless steel work surface

The cabinet is available in a three-part, removable, mirror finish 316-grade stainless steel, consisting of profiled air in-take grilles to guarantee efficient airflow.

Touchscreen control interface

The Visionaire® technology built into the Biological Safety Cabinets enables the greatest level of operator monitoring, thereby allowing users to regulate every essential aspect of product operation.

Infra-Red Intelligent Sash Safety (IRISS)

The IRISS system projects an infra-red beam throughout the base of the opening. Should this beam be broken, the sash closure will be instantly and automatically aborted, preventing potential injury or damage.

Biosafety for users’ requirements

Class 2 Biological Safety Cabinets offer Three Levels of Protection

Air Inflow safeguards the Operator, HEPA-filtered Downflow prevents cross-contamination and protects the Sample, and HEPA-filtered exhaust protects the Environment.

Type A2

As far as a Recirculating Type A2 MSC is concerned, the air is drawn in through the front aperture, offering operator protection. The inflow air mixes with the downflow air as it enters the front intake grille and passes via the plenum, where the air is split into exhaust systems.

- Around 70% of the air is recycled and pushed back into the Work Area via the downflow HEPA Filtration, thereby offering product protection.

- 30% is returned via the Exhaust Air HEPA Filter back into the laboratory surrounding.

Type C1

A Type C1 MSC uses the same airflow pattern as a Type A2. The Anti-Blowback Valve guides around 30% of Exhaust Air through an External Duct System.

Carbon Exhaust System

If chemicals are utilized, a Carbon Filtered Exhaust system might be installed after or as part of the Exhaust HEPA Filter, thereby making a Type A2 Cabinet ideal for handling dangerous chemicals.

Image Credit: Monmouth Scientific Limited