Track particles in real-time to monitor and improve processes. Particle size and count analysis—as particles exist in-process.

The probe-based ParticleTrack available from Mettler Toledo uses FBRM® technology to study particle size and count analysis in real-time. Users can get real-time measurement of shape, count, and size of the particles:

- Direct in-process measurement without by-pass loops or sampling

- Isolated areas (fine and coarse) of the particle population can be analyzed

- Users can directly see the way process changes affect particles

- Monitor particles from 0.5 to 1000 μm at most of the process concentrations

- Particles in opaque or translucent emulsions and slurries can be studied

Particle Size Analysis at Full Process Concentration in Real Time

Video Credit: METTLER TOLEDO

Inline versus offline particle size distribution analysis

Particle size analysis is usually performed offline under controlled conditions. This offline method provides a reliable technique to guarantee the quality and uniformity of particle-based products. But offline particle size analysis can lead to sampling errors and time delays, making process optimization complicated. By learning particle count and size in-process, researchers can get data they require to enhance processes rapidly and confidently.

Focused Beam Reflectance Measurement (FBRM®)

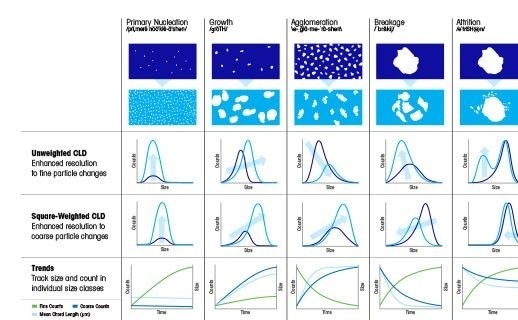

FBRM® is the industry-standard measurement method utilized for the in-process measurement of particles. A highly accurate chord length distribution (CLD), sensitive to the count and size of particles, is reported in real-time without requiring preparation of sample or sampling. None of the shapes is assumed, and the measurement can be performed at complete process concentrations in translucent or opaque emulsions and slurries.

ParticleTrack With FBRM Method of Measurement – Technology Introduction – METTLER TOLEDO – en

Video Credit: METTLER TOLEDO

Study particle size and count over time

Researchers introduce ParticleTrack probes directly into process streams to detect the count and size of particles constantly over time without the need for taking a sample. This exclusive data turns out to be the basis for gaining effective insights into each process in which droplets, particles, and crystals are involved.

Image Credit: METTLER TOLEDO

Link the process to the particle system

By making use of ParticleTrack with FBRM® technology, researchers can regularly identify how particle systems are affected by process parameters. The effect of process parameters on mechanisms like growth, agglomeration, disintegration, and change in shape can be determined. This enables processes to be enhanced and optimized with evidence-based techniques.

Image Credit: METTLER TOLEDO

Will ParticleTrack work for a user’s application?

ParticleTrack powered by FBRM® technology is utilized for in-process measurement in several industries ranging from research to manufacturing. The common areas of application:

- Precipitation and crystallization

- Disintegration and dissolution

- Liquid formulations

- Ensuring flow in gas and oil production

- Flocculation

Image Credit: METTLER TOLEDO

Create fit-for-purpose particle systems

ParticleTrack is used by researchers to identify how particles with the preferred count and size can be consistently delivered. Researchers can select improved process parameters at the time of development, via scale-up and into production, thereby providing high-quality particle products to the market quickly at a lower total cost and enhanced with evidence-based techniques.

Image Credit: METTLER TOLEDO

Monitor and correct process deviations

ParticleTrack powered by FBRM® technology is applied to supervise, troubleshoot, and enhance established processes in production. It is possible to safely monitor complex processes, where sampling is a problem, thus guaranteeing consistent production of particles with the highest feasible quality.

Image Credit: METTLER TOLEDO

Monitoring particle mechanisms

ParticleTrack powered by FBRM® technology is employed to supervise the particle systems as they vary over time. Mechanisms like growth, agglomeration, and disintegration can be determined, measured, and related to the parameters selected for the process.

Image Credit: METTLER TOLEDO

Why is particle size important?

Particles, droplets, and crystals appear in several chemical processes. These features pose difficulties in improving process efficiency and product quality. The effective characterization of properties of the particles, in the specific particle count and size, enables product quality to be enhanced and processing issues to be resolved.

Image Credit: METTLER TOLEDO