Sponsored Content by ADMETFeb 14 2020

In the United States, heart disease is the leading cause of death among adults. Vascular stents are vital medical devices that are used to ensure patients increase their life expectancy and lead healthier lives. There is a wide range of stents that vary in size and strength for a variety of applications. Mechanical testing of a vascular stent comprises testing the device specimens in several failure modes. These include bending, tensile, torsion, abrasion, crushing, and fatigue.

Image Credit: Admet Inc.

Vascular Stents

To guarantee the success of a medical product, safety and efficacy are imperative. Vascular stents are hollow tubular structures that are implanted in the native or grafted vasculature. They are Class III medical devices that need premarket approval. Their intended use is as a mechanical radial support to improve vessel patency over the intended design life of the device. Extensive testing is undertaken on universal testing machines to determine the device properties and its intended use.

Mechanical Tests

If a loaded stent fails, it can lead to loss of radial support of the stented vessel or vessel perforation by the stent struts. Stress-strain analysis, in combination with fatigue analysis and accelerated durability testing, indicates the durability of the device. Included below are the types of mechanical tests that may be performed on vascular stents.

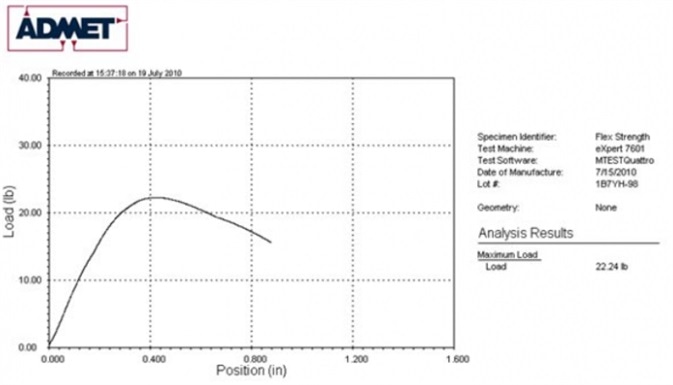

Bend Testing

To characterize deployed stent flexibility and pre-deployment stents system flexibility, bend testing is required in the area of the stent and the balloon. The bending flexibility of the stent is attained using force-versus-deflection plots and/or midspan bending moment versus midspan curvature plots. However, this does depend on the test procedure followed. ASTM F2606 offers guidelines on three-point bending procedures on balloon-expandable stents and stent systems.

Figure 1. This test report shows flexural strength. Image Credit: Admet Inc.

Recommendations suggest studying the bending flexibility of vascular stents. In addition to stent systems and delivery systems.

- Deployed stents: The bending flexibility of deployed stents demonstrates the bending properties of the vascular stent and note whether these properties imitate the natural curvature of the vessel.

- Stent systems: these are delivery systems with pre-mounted stents. Bending flexibility measures how the system can track the vascular anatomy and determine whether vascular trauma can occur along the delivery pathway distal to the guide catheter.

- Delivery system: The bending flexibility of a delivery system includes a catheter at the target site that is used to deliver and deploy a stent. It aids the assessment of separate contributions of the delivery system, in addition to how the mounted stent affects the total flexibility of the stent system.

Bend tests can be completed using fixed/variable span lengths.

- Fixed span length bend test: the method will allow comparisons between force versus deflection and are independent of stent length.

- Variable span length bend test: the method allows the bending moment arm length to be maximized for all stent lengths. This minimizes the possibility of non-bending deformation at a given applied load and/or deflection. Comparisons in bending flexibility can be made at different span lengths. This is done by making a comparison between the midspan bending moments at given midspan bending curvatures. Then, the bending load variation with span length may be investigated.

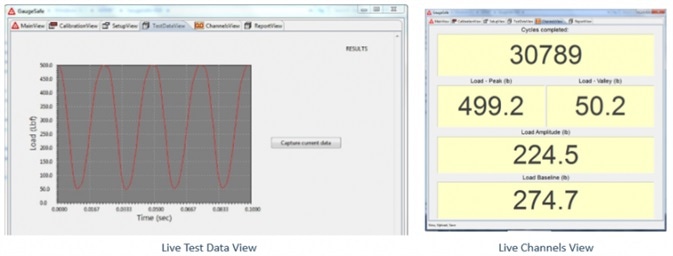

Fatigue Testing

Fatigue testing is needed to indicate the stent failure due to typical cyclic blood vessel diametric distention. This is defined as the variation in the blood vessel’s inner diameter due to a pressure change that occurs with each pulse of blood circulation.

It assesses failure modes such as fretting, abrasion, fracture, and wear. Physiologically relevant diametric distention levels are exposed to the vascular stent through hydrodynamic pulsatile loading. This is done by injecting a certain volume of fluid into the confined test volume. The normal test duration per ASTM F2477 is 10 years equivalent at 72 beats per minute, or a minimum 380 million cycles.

Live display during fatigue testing. Image Credit: Admet Inc.

Radial Loading

Radial loading is needed to indicate whether the vascular stent has satisfactory resistance to forces that act upon it and uphold vessel patency. It is directed perpendicular to the longitudinal axis of a cylinder and then applied to the outside surface of the cylindrical stent. The resistance to these loads is dependent on the type of device and the clinical concern. It can be presented through numerous test outputs: collapse pressure, radial strength, or chronic outward force.

ASTM F3067 summarizes procedures for radial testing of stents. Dependent on the standard, radial testing of stents will vary, considering the stent type: whether it is balloon-expandable versus self-expanding. Another consideration is which apparatus is used: whether it is segmented head, sling, or hydraulic/ pneumatic. The apparatus is chosen with clinical effects in mind and is limited by the stent type.

Tensile Testing

To determine the yield strength, ultimate tensile strength, and elongation of materials used in developing the vascular stent, tensile testing is required. In vascular stent formation, if nitinol is used as raw material, the plateau stresses and elastic strain limits also need to be tested and specified.

ASTM F2516 includes the tension testing of Nickel-Titanium superelastic materials. In addition, FDA recommends making a report on the stress-strain response of the stent post deployment. Additional post-processing mechanical properties to note are Poisson’s ratio, elastic modulus, and endurance limit.

Torsion Testing

Torsion testing is suggested for stent delivery systems that require the need to withstand torsional forces. If this testing does not demonstrate what is needed successfully, it may result in vessel damage or device failure. When the distal tip of the stent delivery system is not free to rotate, the torque strength should be measured by rotating the proximal end of the catheter until it fails. Important information to note is the number of rotations to failure and the failure mode for each sample tested.

Additional tests may be completed depending on the type of vascular stent, its intended use and its location. These tests include crush resistance, corrosion, kink resistance, coating integrity, and more.

Note: Metal vascular stents can result in thrombosis at the treatment site, or cause inflammation scarring. An alternative has been developed; drug-eluting stents. They decrease the potential for restenosis over an extended period. Drug-eluting stents are also known as drug delivery vehicles and are developed with pharmacologic agents. They follow a different regulatory pathway compared to metallic vascular stents. Before testing, it is vital to follow the appropriate guidelines and the relevant test procedures based on the materials used in the development of the vascular stent.

Testing Equipment

ADMET testing systems are instruments with versatile testing capabilities over a wide variety of materials and products. In recent years, ADMET has worked with several medical device manufacturers to progress with testing solutions that will guarantee their products meet the essential specifications.

ADMET’s MTESTQuattro controller software supports the requirements of FDA CFR 21 Part 11 by generating a documentation trail to track changes in test procedures. A record is created which reports what was changed, when, and by whom.

eXpert 4000 MicroTester

eXpert 4000 MicroTesters are intended to work in combination with microscopes and can be set up with submersible load cells and fixtures in baths to test medical samples in liquid environments.

This video presents a custom testing application where tensile fatigue loading is applied to rubber rings using the eXpert 4000 frame. It has an attachable bath and submersible fixtures.

Micro Tensile Fatigue Test in Liquid Bath - ADMET Micro EP

Video Credit: ADMET

eXpert 5900 Fatigue Testing Systems

eXpert 5900 series tabletop dynamic testing machines are quiet, compact, electrodynamic testing systems for indicating materials and components durability in tension, compression or flexure. ADMET’s dynamic fatigue testing systems give users a choice of two controllers: the MTESTQuattro high-speed closed-loop controller, or the DC1X Dynamic Fatigue Controller.

eXpert 5900 fatigue bend testing. Image Credit: Admet Inc.

Programming MTESTQuattro can generate sine, square and triangular waveforms. Users of the machine can manually alter control gains and endpoint values on the fly or trigger amplitude control so that the controller alters the endpoint values automatically to guarantee that the dynamic fatigue testing systems targets are achieved.

The DC1x controller is a perfect and cost-effective solution for basic cyclic fatigue testing applications and it offers basic sine, square and triangle waveforms. A standard compensation program is amplitude control which tracks the feedback signal and adjusts amplitude and setpoint control values automatically until the wanted peak and valley levels are met. It is perfect for cyclic tests under load control in which specimen or test system characteristics differ over time. During tests, users can view peak/valley and number of cycles completed.

eXpert 7600 with pneumatic grips. Image Credit: Admet Inc.

eXpert 7600 Single Column Universal Testing Systems

eXpert 7600 series machines can perform an array of mechanical tests on vascular stent specimens. These include tension, puncture, compression, and more.

If a user’s testing needs further options than ADMET standard systems can deliver, the company can modify the stroke or speed, or add a torsion actuator for biaxial tests to meet the user’s needs. The 8 kHz servo loop rate guarantees repeatable, accurate and reliable testing.

eXpert 9000 Torsion Testing Systems

eXpert 9000 series tabletop torsion testing machines are offered in two orientations: vertical or horizontal. They are used for static and fatigue testing applications. Maximum torsional stiffness and minimal axial friction is accomplished with a roller slide frame design. A reaction torque transducer can be added to the tailstock, or a rotary torque transducer can be added to the drive spindle to allow the use of a large range of applications.

The horizontal machine allows the tailstock to be left free-floating or clamped during testing. A deadweight pulley system is provided with all torsion testers to apply uniaxial tensile or compressive forces. All torsion testers feature unrestricted rotation in both directions.

Conclusion

For all tests performed, full test reports are written and included for premarket approval of vascular stents.

Testing helps to support the safety and effectiveness of devices. Regulatory approval needs to include test specimen information, test protocols, protocol deviations, and test parameters. In addition to this, acceptance criteria, raw data, test results, and data analysis are included.

Conclusions from the results and the clinical significance of these conclusions are also suggested for the final proposal. Mechanical testing should be completed by universal testing systems that are accurate, and equipped with controls and software that produce reliable and repeatable results.

About ADMET

ADMET, Inc. is a leading provider of universal testing systems for tension, compression, flexure, torsion and biaxial testing. Leading companies, universities, government agencies, and research laboratories have trusted ADMET to provide them with universal testing solutions in applications ranging from concrete to biomedical tissue adhesives.

ADMET offers a full range of test systems with capacities from 50 grams to 600 kN; capable of both static and fatigue testing to 20 Hz. ADMET also provides grips, fixtures and other accessories to meet a diverse set of testing requirements. Standard systems are designed to perform tests according to ASTM and ISO test standards.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.