Medical ventilators are advanced air circulation systems engineered to facilitate breathing for a patient unable to do so independently. A variety of medical ventilators are available for use in different medical environments.

Image Credit: Superior Sensor Technology

A variety of medical ventilators are available for use in different environments:

- Transport ventilators: First responders, ambulance services, and helicopter transport use transport ventilators. In emergencies, these electronic ventilators supply breathing assistance until a patient is transferred to a hospital. They are more compact and robust than their hospital counterparts and offer diverse power source options.

- Intensive care (ICU) ventilators: Large ventilators are located in hospitals and powered by AC electricity. They are used in the surgical and ICU areas and offer comprehensive features and capabilities.

- Critical care ventilators: Although lacking some of the features of ICU ventilators, critical care ventilators are equipped with enough functionality to manage emergencies and long-term critical ventilation situations. These ventilators tend to be found in hospitals’ emergency and specialized care units.

- Home ventilators: These smaller devices assist patients who cannot breathe independently after discharge. A home ventilator continues to support a patient’s breathing until they can do so without assistance.

Neonatal ventilators are medical ventilators designed explicitly for neonatal and infant patients. The key difference is that they are intended to provide lower and more precise rates of ventilation.

Modern medical ventilation systems are controlled electronically, with embedded processing that precisely regulates air pressure and flow according to each patient's specific requirements. These systems are considered to be life-critical because a system failure could cause severe patient harm.

Before the COVID-19 pandemic, medical ventilators were fundamental to hospital care. However, the demand for ventilators has risen substantially over the last few years.

Hospitals routinely use high-pressure ventilators, which are tank-based and built into the infrastructure. However, the current trend in medical ventilation is towards portable solutions, specifically low-pressure units. These mobile units are equipped with a miniaturized O2 tank or can function without one.

Ease of transport is a major advantage of these devices. They can provide increased mobility for the patient and be easily relocated when required.

These modern systems have a blower mechanism that produces the required air on demand instead of full-sized tanks. The blower operates like a standard fan, using blades to create airflow. The blades' noise is a challenge, and it must be addressed to guarantee accurate and efficient operation.

Figure 1. Examples of low-pressure medical ventilators. Image Credit: Superior Sensor Technology

Superior Sensor VN Series improves ventilator performance

A number of medical studies have suggested that approximately one-third of patients experience dyssynchrony during mechanical ventilation. This is when the ventilator does not match the patient’s breathing requirements.

This can result in increased respiratory work, lung damage, discomfort, extended ventilator reliance, and weaning difficulties. To improve synchrony, ventilators must respond faster to patient breathing demands and eliminate the impact of system noise.

Pressure sensors in ventilators, crucial for monitoring and controlling airflow, can be affected by system noise from internal blowers and external vibrations. Traditional systems often slow down response time by oversampling sensor data, further complicating the issue.

Designed specifically for medical ventilators, the VN Series by Superior Sensor uses an innovative oversampling technique that effectively eradicates all noise beyond the relevant band. This proprietary technology allows mechanical ventilators to use sensor outputs at their maximum speed, eliminating the requirement for oversampling sensor outputs and decreasing the system response time by as much as tenfold.

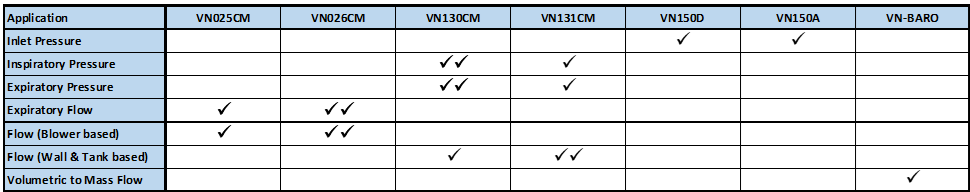

The series is made up of seven devices, each of which caters to a broad spectrum of system applications, ranging from flow measurement to inlet, inspiratory, expiratory, and barometric pressures.

Advanced digital processing significantly reduces system-level noise interference. Additionally, the sensors boast 24-bit output resolution, improved filtering, remarkable zero stability, and are capable of supporting an update rate surpassing 1 kHz.

They have been meticulously designed to enhance system accuracy and reduce error rates. This proves especially advantageous for patients facing life-threatening respiratory conditions.

The table below highlights the uses of different sensors within the VN Series.

Table 1. VN Series product family. Source: Superior Sensor Technology

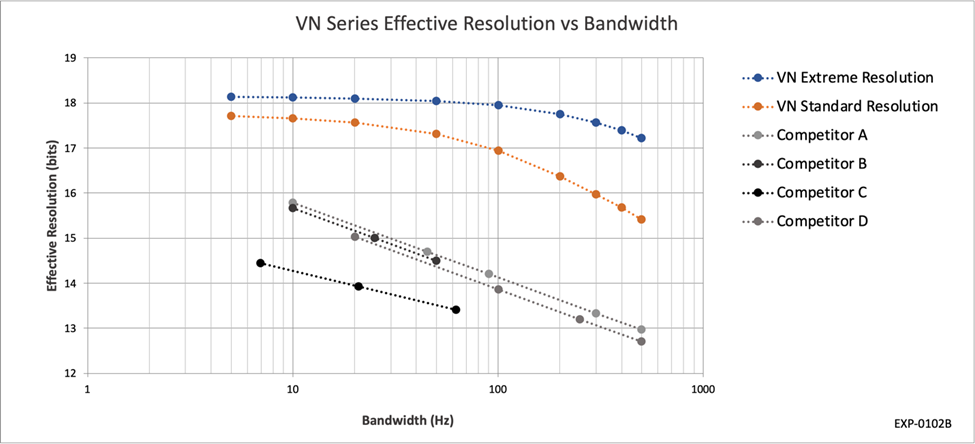

The VN026CM and VN131CM offer extreme bandwidth resolution, enhancing the sensor’s effective resolution, amplifying the dynamic range, and reducing the noise floor by an additional 20 dB.

The VN026CM and VN131CM have the lowest noise floor and, for the first time, can offer manufacturers single-sensor solutions catering to numerous respiratory requirements for neonates and adults.

Graph 1. Comparing extreme resolution to standard resolution and competitive offerings. Image Credit: Superior Sensor Technology

The VN Series sensors have integrated additional features like advanced digital filtering and a three-mode pressure switch. These transform pressure sensors into sensing subsystems, increasing manufacturing efficiency and reliability.

Every VN Series sensor uses the same footprint and is pin-compatible with each other. The simplified PCB layouts allow manufacturers to easily interchange VN Series sensors for a variety of applications.

Conclusion

The VN Series employs cutting-edge digital signal processing and noise filtering methods to enhance medical ventilator performance. By facilitating rapid sensor data retrieval and eliminating interference, the sensors enable ventilators to adapt promptly and precisely to patient breathing patterns.

This heightened speed and accuracy, coupled with advanced functionalities such as three-mode pressure switching, can notably enhance patient-ventilator synchronization and minimize discomfort.

Offering industry-leading resolution and noise reduction within a standard footprint, the VN Series provides ventilator manufacturers with a flexible pressure-sensing solution to enhance system dependability and more effectively cater to the needs of critical care patients.

Major global ventilator manufacturers, like Vyaire, trust Superior Sensor Technology to supply their differential pressure sensors.

About Superior Sensor Technology

Superior Sensor Technology is an innovative, high technology company revolutionizing the high performance, cost driven pressure sensor market by developing integrative, highly intelligent solutions for industrial, HVAC and medical applications.

Our proprietary pressure sensor technology with advanced programmable software features enables customers to develop higher performing, more reliable equipment.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.