Sponsored Content by OpentronsReviewed by Louis CastelMar 29 2024

Volatile liquids, liquids that evaporate readily at room temperature, are common reagents in various applications. For instance, acetone, methanol, isopropanol, and ethanol, particularly for different nucleic acid purification techniques. The volatility rate, often known as the rate of evaporation, rises exponentially with temperature.

These liquids are difficult to pipette, even at room temperature, with the most frequent issue being dripping out of the tip. The constant evaporation of volatile liquids also presents certain challenges for pipetting. Higher vapor pressure results in faster evaporation of the liquid and faster ejection of liquid out of the tip.

When it comes to volatile liquids, a rise in temperature causes the liquid to become more volatile, which in turn raises the vapor pressure and evaporation rate. On the other hand, the liquid’s volatility and related properties are reduced when it is diluted.

In this article, Opentrons provides some recommendations for improving liquid handling for often automated volatile liquids, such as different isopropanol and ethanol concentrations.

Key volatile liquid handling techniques

Pre-wetting tips - mix()

Pre-wetting is a pipetting technique that involves continuously aspirating and dispensing a predetermined volume of the liquid to be aspirated. Volatile liquids have a high vapor pressure, which causes the air gap between the nozzle and the liquid surface to grow and force the liquids out of the tip.

To assist in maintaining a lower vapor pressure, pre-wetting saturates the vaporized solvents in the air gap between the nozzle and the liquid surface.

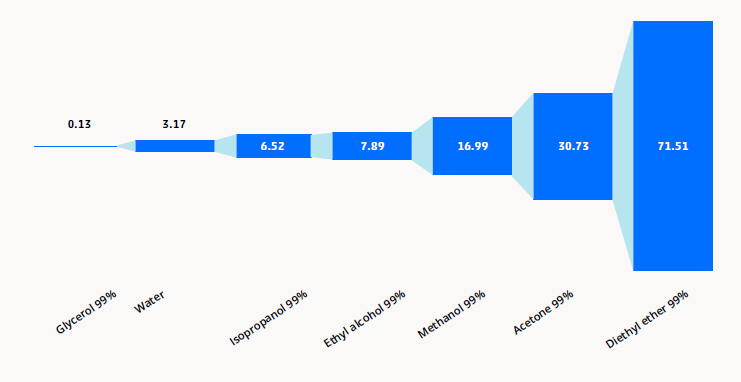

Figure 1. TVapor pressure (kPa) of commonly used volatile liquids at 25 ˚C. Image Credit: Opentrons

Trailing air gap aspirate - aspirate(), move_to()

To prevent spilling, one option is to maintain air at the tip orifice. The size of this air gap depends on factors such as the vapor pressure of the liquid, the volume of liquid aspirated, and, importantly, the time it takes for the tip to move from the deck position where aspiration occurs to the position where dispensing occurs.

The density of most volatile liquids is less than that of water (<997 kg/m3). When air is aspirated following the volatile liquid aspiration, the liquid inside the tip accelerates upwards, which can cause clogging of the filter or pipette nozzle.

It is necessary to keep the trailing air gap flow rate speed extremely low to prevent such an issue. Higher vapor pressure liquids, such acetone, diethyl ether, etc., produce the “tears of wine” effect, in which rings of liquid are passed through the following air gap and leave a gap between the aspirated liquid and liquid at the orifice, further dripping off the tip.

Post-dispense delay - protocol.delay()

Accurately dispensing volatile liquids hinges on two key factors. Firstly, because of their lower surface tension, these liquids tend to adhere to the interior surface of the tip, gradually moving towards the tip orifice after the bulk of the liquid is dispensed.

Secondly, the formation of alcohol rings, commonly referred to as wine tears, results in liquid adhering above the liquid surface, sliding towards the tip orifice, and creating a dead volume. Incorporating a post-dispense delay helps minimize this dead volume.

Double blowout - blow_out()

Additional blowouts can be added for full dispensing. To execute a second blowout, remove 1 µL of air from the liquid by withdrawing the tip. Then, do a second blowout (in or out of the liquid). By aspirating 1 µL of air, the plunger can maintain its original position with minimal movement.

Optimization strategy for volatile liquids

Step 1

Hover to the top of the aspiration well and submerge the tip slowly.

Step 2

To accomplish prewetting, immerse the tip in liquid. Determine the number of prewetting stages based on the volatility of the liquid. The Python API’s mix() function allows users to combine liquid “n” times.

Step 3

aspirate() volatile liquid at water calibrated the flow rate.

Step 4

The tip withdrawal speed must be reduced to 50 mm/s for most of the volatile liquids. This prevents liquids from being splashed on the labware walls. move_to() the top of labware at 50 mm/s.

Step 5

The air gap volume can be adjusted as per the vapor pressure. The pipette.flow_rate. aspirate() of the air gap must be kept 1/20th times the water flow rate for the respective pipette.

Step 6

dispense() volatile liquid with a tip immersed <2.5 mm below the liquid at water calibrated flow rate. This prevents an increase in dead volume.

Step 7

Add protocol.delay() of 3 - 4 seconds depending on the vapor pressure of the liquid. By adding this delay, the liquid can settle at the tip before performing a blowout.

Step 8

Perform pipette.blow_out() at a water-calibrated blowout flow rate.

Step 9 (Optional)

If excess liquid remains inside the tip after the initial blowout, the user can withdraw the tip using the move_ to(well.top()) and aspirate() 1 µL of air and immerse the tip (move_to()) inside the liquid and perform a second blowout

Step 9

If required, execute touch_tip() at a location depending on the necessary height inside the labware.

Step 10

Remove the tip, move_to(well.top()) at a slower flow rate of 50 mm/second.