The measurement of dissolved oxygen (DO) in cell culture applications is one of the most common applications of oxygen sensors in biopharmaceuticals.

Oxygen is a critical process parameter needed for cell growth. Cells are grown in a bioreactor, where oxygen is sustained at around 30 to 60% air saturation. Inadequate oxygen stresses the cells, restricts growth (hypoxia), and possibly triggers cell death (anoxia). Excessive oxygen concentrations can cause foam buildup within the vessel and even oxygen toxicity.

DO sensors employed in bioreactor applications can be either optical or polarographic. These sensors need a hygienic design and the capability to endure sterilization (autoclave or steam-in-place) and chemical cleaning (clean-in-place).

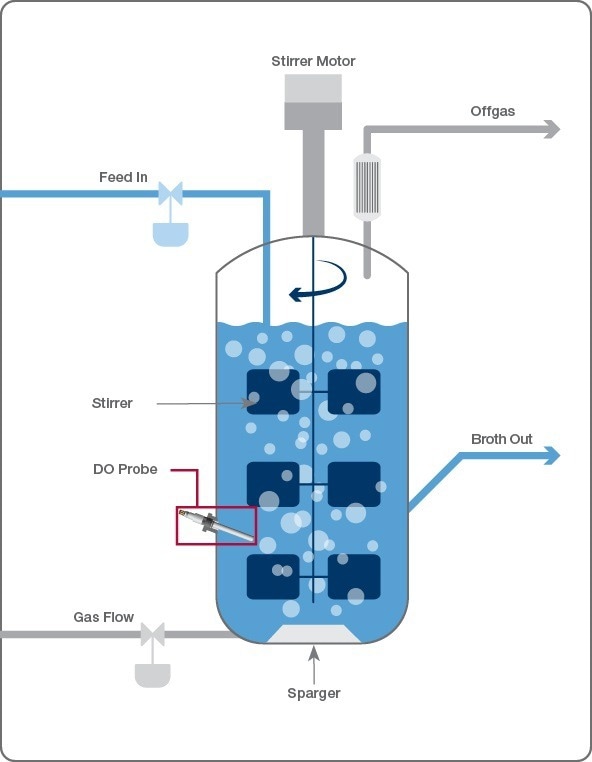

Basic bioreactor layout. Image Credit: Hamilton Company

Hamilton offers optical (VisiFerm® family) and polarographic (OxyFerm® FDA) DO Sensors for biopharmaceuticals.

About Hamilton Company

Hamilton Company specializes in the development, manufacturing and customization of precision measurement devices, automated liquid handling workstations, and sample management systems. Hamilton's processes are optimized for quality and flexibility. Whether it's a custom needle with a quick delivery time frame, a special length pH sensor, or a comprehensive solution to fully automate your assay workflow, trust that Hamilton products will always meet your needs.

Hamilton Company has been a leading global manufacturer for more than 60 years, with headquarters in Reno, Nevada; Franklin, Massachusetts; Timișoara, Romania; Bonaduz, Switzerland; and subsidiary offices throughout the world.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.