In this interview, Niall Dinwoodie, Executive Director for Gene Therapy for Charles River in Europe discusses the opening of their new HQ Plasmid Center of Excellence at Alderley Park.

The site which opened in October will support therapuetic developers with rapid access to high quality (HQ) plasmid DNA, a critical starting material in the develpment of potentially transformative cell and gene therapies.

Please can you introduce yourself and tell us about your professional background, as well as your current role with Charles River?

My name is Niall Dinwoodie. I'm the Executive Director for Gene Therapy for Charles River in Europe. I've been with the company for just over 35 years. I joined as a laboratory analyst and have been part of the expansions of the laboratory and testing operations at Charles River. As the business has grown, I've developed with it. I've managed facilities in the UK and the US, mainly on the testing side.

When Charles River was looking to acquire the Cobra Biologics/Cognate Bioservices organization and become involved in the CDMO (contract development and manufacturing) business, I became involved in the acquisition process, doing the due diligence for the site. Starting the integration of those companies into Charles River, I know a lot of people within the organisation, so I can help new businesses connect and find the people they want to talk to. Then one thing led to another, and now I manage the business instead of just helping it integrate.

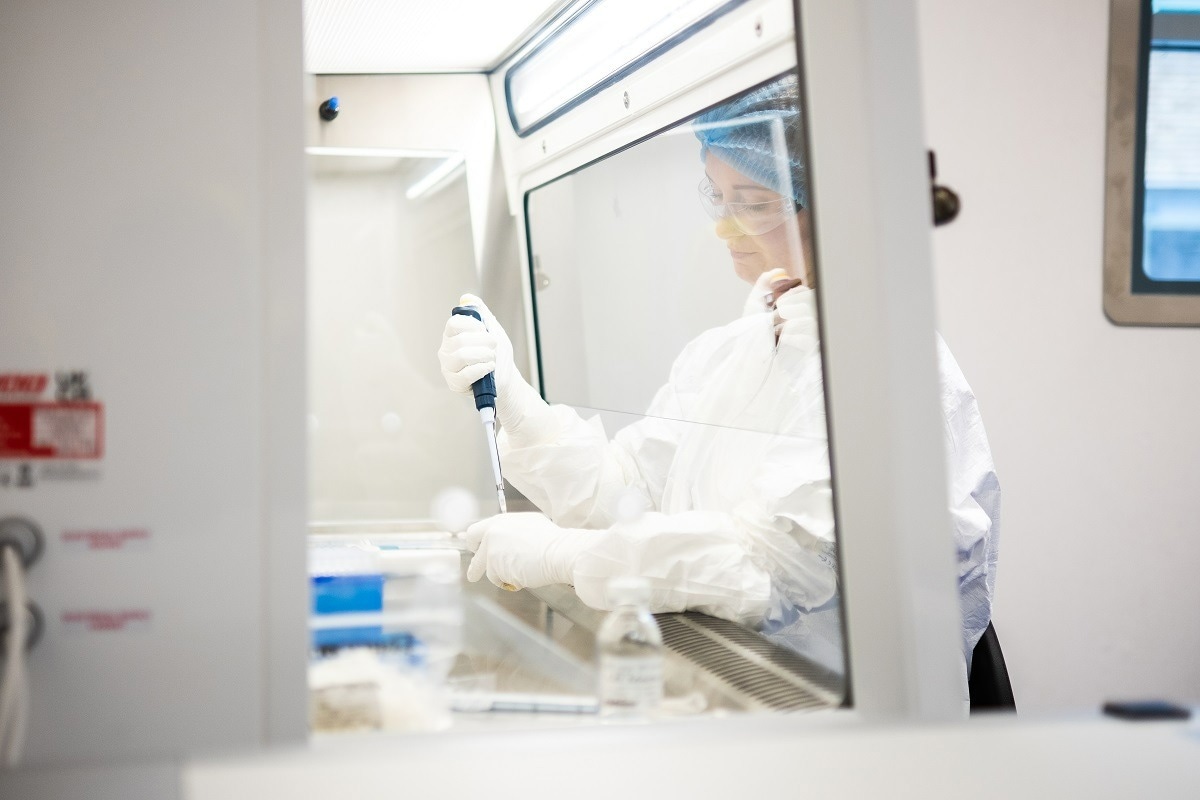

Image Credit: Charles River

You look at the advances that have happened over the last few years, with gene therapy companies now being in a position where we're no longer just trying to treat a disease; we're able to cure those diseases. This, for me, is just phenomenal and I'm very excited to be part of it.

For example, my first job was working at Ninewells Hospital in Dundee, analyzing the blood from neonatal patients who were believed to have genetic diseases. At that time (more than 30 years ago), we could analyze the blood. We could try and find out what was wrong, but in many cases, unfortunately, the infants died before we could even identify what was missing from their genetic makeup. Now with genetic sequencing and gene therapy, there is the potential to not just treat, but cure such patients.

Charles River was founded over 70 years ago as a very different company in a very different world. Could you tell us a bit about the journey and development of Charles River as a company and how the founding vision of the company is still maintained today?

The company was founded by Henry Foster as a supplier for laboratory animals to ensure that there was a consistently high quality, rapidly available supply for pharmaceutical researchers. For a long time, the company was an animal supply company.

However, in the early 2000s, the company started acquiring safety assessment businesses. So basically, getting to the next stage of support for pharmaceutical companies. In the last 15 years or so, I would say we've grown quite dramatically. Both through acquiring additional businesses, but also organically developing our services so that we can provide support along the full continuum of the pharmaceutical development process. This starts right from early discovery through all the safety testing, all the quality control for manufacture, and now with the CDMO business, actual manufacturing itself for gene therapy products.

As a prominent, longstanding company within the life sciences industry, what do you believe to be some of the biggest advancements the sector has made over the last decade?

I'm particularly interested in the gene therapy so genetic sequencing, and being able to combine that with artificial intelligence and modeling to be able to get a much better understanding of the true causes of disease. Identifing potential targets to either cure or treat those diseases, and then to speed up the process of getting those new products onto the market by refining the testing models that we use has vast potential.

We are here today to celebrate the opening of the new contract development and manufacturing center of excellence at Alderley Park. How will this new facility allow Charles River to continue supporting the cell and gene therapy industry? Can you tell us about some of the services this facility will provide?

This facility is expanding our capabilities in the gene therapy market. For several years, we've manufactured plasmid DNA at our facility at Keele. The demand we've been having for our services is such that we wanted to increase what we could do, and we didn't have the footprint there.

Image Credit: Charles River

This facility has been opened with three additional manufacturing streams, but the way we've designed the facility and the infrastructure we have put around it allows us to produce those batches far more rapidly than previously. So, what we can do with this site is really reduce the lead time for plasmid DNA. Typically it's been around 13 weeks, however from this facility, we can get it out in five.

The facility's key offering will be High Quality (HQ) plasmid DNA production. What is HQ plasmid DNA, and how can this service help accelerate the development of cell and gene therapies?

High quality plasmid DNA is targeted at clinical trials. If a client is using a viral vector in a clinical trial and that viral vector requires DNA, then they can use high quality material rather than the full GMP ('good manufacturing practices') standard material. It's the same process and the same level of quality control, but there are differences in the design of the facilities and in the supporting documentation and administration.

Charles River Laboratories Alderley Park HQ Plasmid Center of Excellence

The opening of the new facility at Alderley Park is a face-to-face event, something that we have not been used to since the onset of the COVID-19 pandemic. How did the COVID-19 pandemic impact operations at Charles River, and how does it feel to be back to face-to-face events?

For Charles River, the COVID-19 pandemic has been our busiest time. All our facilities around the globe have been working with vaccine developers to get those materials onto the market as rapidly as possible, whilst maintaining all the quality standards and all the checks that we need to put in before material is released.

Image Credit: Charles River

In our Keele facility, we manufactured the clinical trial material for the Oxford/AstraZeneca vaccine. Our staff have worked incredibly hard under very trying circumstances but have had the real benefit of seeing those vaccines getting out there, being used to treat their families. So it's probably been, as well as some of the most challenging times, the most rewarding times.

Regarding face-to-face, Charles River has been working through the pandemic, so we have had a lot of time together with our colleagues. Looking outside the company, having in-person meetings and getting people on site here at Alderley Park gives them confidence in all that we say about the material we produce, and the quality we are providing. To see it in the facilities makes all the difference.

What's next for Charles River? Are you involved in any exciting upcoming projects?

The next thing we're doing is utilizing the space we have freed up at Keele to add an additional manufacturing stream for GMP plasmid. Again to service the increasing demand and to cut our lead times. Beyond that, we are looking at a significantly larger facility to support full manufacturing scale material again in the local area.

Where can readers find more information?

About Niall Dinwoodie

Niall has worked at Charles River for over 35 years in the testing/manufacturing divisions.  Originally in GMP Quality Control, mainly as a manager responsible for the release of test results for licensed products to client companies and later as the Director of Analytical Services globally, Niall lead the integration of Charles River's newly acquired CDMO business in Europe and is now responsible for those activities. He has been a European Qualified Person for investigational medicinal products.

Originally in GMP Quality Control, mainly as a manager responsible for the release of test results for licensed products to client companies and later as the Director of Analytical Services globally, Niall lead the integration of Charles River's newly acquired CDMO business in Europe and is now responsible for those activities. He has been a European Qualified Person for investigational medicinal products.