The printing of biocompatible materials, cells, growth factors, and other supporting components required to produce functioning, complex living tissues is known as 3D bioprinting. Several types of tissue, including skin, bone, vascular grafts, and cartilage structures, have been produced via 3D bioprinting.

Hard and soft tissues can be produced using various materials and compositions depending on the desired qualities. Although there are other 3D printing techniques, extrusion-based techniques using bioinks are the most frequently utilized because of the materials' sensitivity.

Application

Hyaluronic acid, alginate, and gelatin are three natural polymers used to make the HAMA-AlgMA-Gel bioink formulation. Hyaluronic acid, commonly known as sodium hyaluronate or hyaluronan, is a natural polymer frequently employed in tissue engineering. It is an anionic, nonsulfated glycosaminoglycan (GAG). Alginate, commonly called sodium alginate or alginic acid, is a polymer produced by brown algae frequently utilized in tissue engineering.

The bioactive peptide sequences found in gelatin are similar to those found in the native extracellular matrix, promoting integrin-mediated cell adhesion and MMP-sensitive enzymatic disintegration, both of which are necessary for cellular activities, including migration, proliferation, and differentiation.

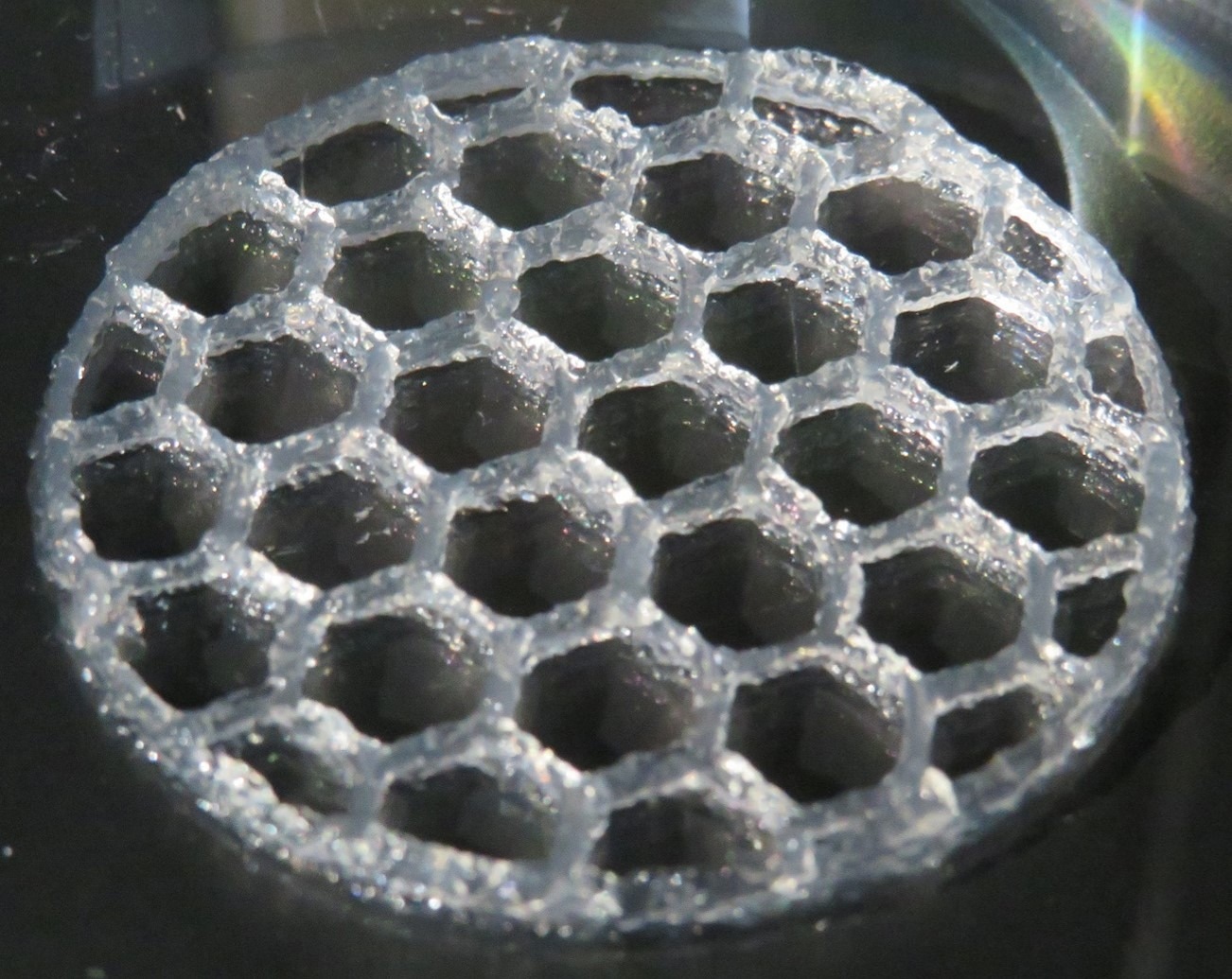

The 3D bioprinting of tissues and constructions using an extrusion-based 3D bioprinter is made possible by the TissueFab® bioink, (GelAlgHa)ma-Vis/405 nm formulation.

TissueFab® bioink, (GelAlgHa)ma-Vis/405 nm formulation can be utilized to bioprint cell-laden hydrogels in the desired shape without the use of any supporting materials. It can be crosslinked in a single step using exposure to UV light to enhance cell culture and maturation for applications in tissue engineering and regenerative medicine.

Image Credit: Merck

Properties

Source: Merck

| . |

. |

| Quality Level |

100 |

| Description |

Validation: HNMR at 40°C |

| Sterility |

Sterile-filtered (0.2 μm) |

| Form |

Viscous liquid (gel) |

| Impurities |

≤5 CFU/g Bioburden |

| Color |

Pale yellow to colorless |

| Viscosity |

2-25 cP(37 °C) |

| pH |

6.5-7.5 |

| Application(s) |

3D bioprinting |

| Storage temp. |

2-8 °C |