3D bioprinting involves the precise printing of biocompatible materials, cells, growth factors, and essential supporting substances to create intricate, functional living tissues.

3D bioprinting has successfully produced various tissue types, including skin, bone, vascular grafts, and cartilage structures. The choice of materials and formulations depends on the desired properties, enabling the creation of both rigid and flexible tissues. Among various 3D printing techniques, extrusion-based methods utilizing bioinks are predominantly employed due to the sensitivity of the materials involved.

3D printed nose structure using TissueFab®-GelAlg-Vis. Image Credit: Merck

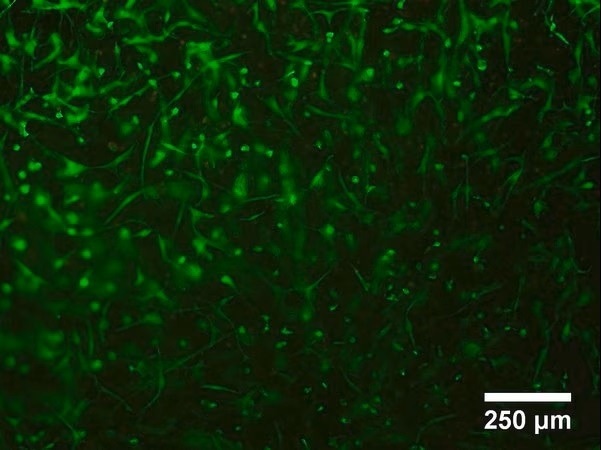

Morphology of hMSC after 7 days post-printing with TissueFab®-GelAlg-Vis. Viable cells were stained with Calcein-AM (green). Image Credit: Merck

Properties

Source: Merck

| . |

. |

| Description |

Suitable for 3D bioprinting applications |

| Form |

Gel form (Viscous) |

| Impurities |

≤5 CFU/g Bioburden (Fungal)

≤5 CFU/g Bioburden (Total Aerobic) |

| Color |

Colorless to pale yellow |

| pH |

6.5-7.5 |

| Application(s) |

3D bioprinting |

| Storage temp. |

2-8 °C |

Application

The Gelatin Methacrylate-Alginate bioink formulation is derived from natural polymers, specifically gelatin and alginate. Gelatin contains bioactive peptide sequences that resemble those found in the native extracellular matrix, promoting integrin-mediated cell adhesion and enzymatic degradation sensitive to matrix metalloproteinases (MMPs). These properties are crucial for cellular functions such as migration, proliferation, and differentiation.

Alginate, a natural polysaccharide widely utilized in tissue engineering, functions as a viscosity enhancer within the bioink formulation. TissueFab® GelAlg-Vis bioink formulation is specifically designed for 3D bioprinting of tissues and constructs using any extrusion-based 3D bioprinter, and is suitable for 3D bioprinting of cell-laden hydrogels into the desired shape.

To facilitate the culture and maturation of cells for tissue engineering and regenerative medicine applications, a combination of chemical crosslinking and visible light-mediated photocrosslinking can be employed to solidify the structure.

Gelatin methacrylate bioinks have proven highly effective in 3D bioprinting, offering exceptional printing resolution, shape fidelity, and cell viability. These bioinks have been instrumental in bioprinting a wide range of tissues and constructs, including osteogenic, hepatic, chondrogenic, adipogenic, epithelial, vasculogenic, endothelial, cardiac valve, skin, tumor, and various other tissue types.

Bioinks containing a combination of gelatin and alginate have also found widespread use in bioprinting 3D constructs, accommodating various cell types such as human mesenchymal stem cells (hMSC), human umbilical vein endothelial cells (HUVEC), embryonic stem cells (ESC), fibroblasts, cancer cells, and more.

Packaging

The product contains 10 ml of bioink packaged in a glass bottle.