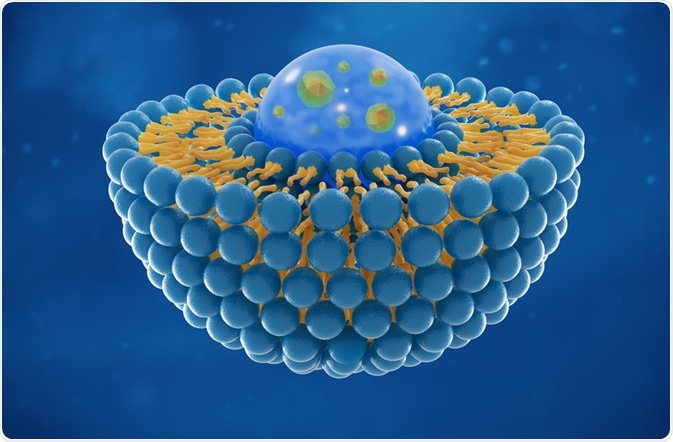

Modern drug delivery systems include the use of liposomes, which means that their characteristics must be fully described for the purpose of manufacturing to specifications and releasing them in batches.

© Tomasz Swierczynski/Shutterstock.com

Such a process of characterization includes assessment of liposome size and the distribution of the sizes of the particles.

Dynamic light scattering (DLS) is a technique in common use for this type of study, in addition to the more recent nanoparticle tracking (NTA) which assesses the size and concentration of liposomes. In this article the utility of the multi-angle DLS (MADLS®) for such measurements over a range of concentrations is described, using the Zetasizer Ultra, in comparison with NTA performed over the same sample.

In this experiment liposomes were measured at 25°C, five times with a Zetasizer Ultra device using the particle concentration parameter, and five times with a NanoSight NS300 using five video recordings lasting 60 seconds each along with the application of a syringe pump and a laser at 405 nm.

Multi-angle Dynamic Light Scattering with the Zetasizer Ultra – How does it work?

Overall, MADLS is a good way to measure particle concentration, and the Zetasizer Ultra makes use of it to measure both liposome size and concentration, showing good agreement with results obtained by NTA in the region of overlap.

A combination of these two techniques is thus highly complementary, as NTA gives the needed precision at lower sample concentrations and greater detail about size distribution, while MADLS allows a larger range of sample concentrations to be measured along with size distribution with rapidity and without the need for sample preparation.

About Malvern Panalytical

Malvern Panalytical provides the materials and biophysical characterization technology and expertise that enable scientists and engineers to understand and control the properties of dispersed systems.

These systems range from proteins and polymers in solution, particle and nanoparticle suspensions and emulsions, through to sprays and aerosols, industrial bulk powders and high concentration slurries.

Used at all stages of research, development and manufacturing, Malvern Panalytical’s materials characterization instruments provide critical information that helps accelerate research and product development, enhance and maintain product quality and optimize process efficiency.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.