Genizer's NanoMixer is a microfluidic mixer designed for laboratory use. This nanomixer prepares mRNA, DNA, siRNA delivery systems, and various other nanoparticles. It is an electronic device that functions without the need for compressed air or hydraulic oil. The NanoMixer facilitates sterile mixing while maintaining minimal dead volume.

The Nanomixer can operate at a working pressure of up to 500 psi. The NanoMixer features temperature control suitable for sensitive biopharmaceutical applications.

How it works

The Nanomixer employs pressure to merge fluids on a microfluidic chip. The injection module forces liquids into the chip. The liquids traverse the micron-scale channels within the chip, resulting in stable laminar flow. At junctions in the chip module, the liquids amalgamate.

This process yields uniform and stable nanoparticles characterized by a narrow size distribution. The NanoMixer is applicable for enhancing solubility and achieving reproducible outcomes.

Features of the NanoMixer

Stainless steel microfluidic mixing chips

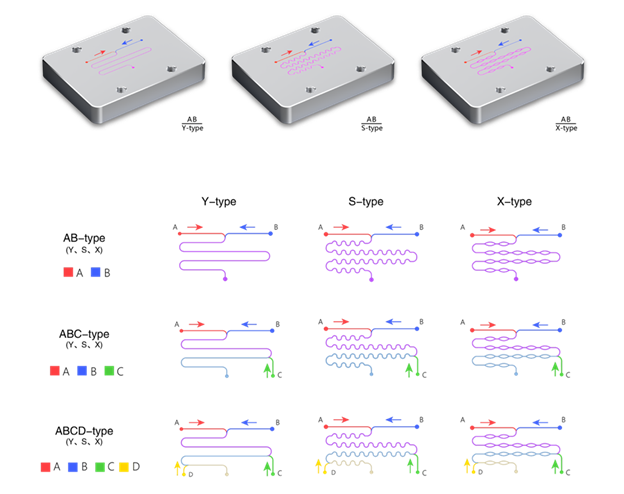

Image Credit: Genizer

The microfluidic chip serves as the essential element of the NanoMixer. Genizer provides a wide variety of stainless steel, reusable chips to ensure optimal versatility and significantly lower consumable expenses compared to competing equipment.

The microfluidic chips offer configuration choices for blending two, three, or four components.

Precision

The NanoMixer features programmable flow rates reaching up to 10 mL/min for each pump, along with adjustable mixing ratios facilitated by gastight syringes. It offers precise sampling capabilities with a resolution of up to 0.1 mL.

The temperature control option ensures stable reaction conditions, leading to optimal results.

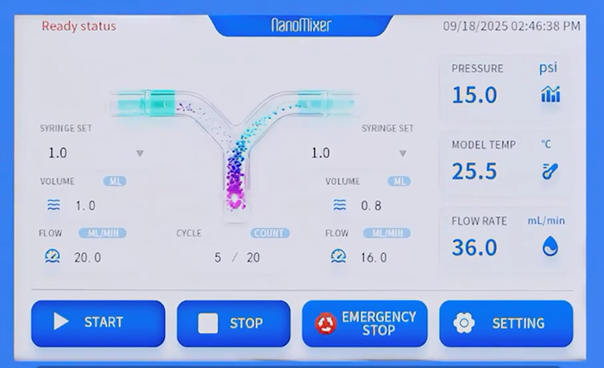

TouchScreen PLC

Image Credit: Genizer

The touchscreen operating system is user-friendly. Settings such as pressure, speed, and volume can be modified.

Compact size

The NanoMixer occupies a small area, featuring a base measuring 36 × 30 cm, which is approximately 14 × 12 inches. This compact design allows it to be a suitable addition to a laboratory benchtop.

Sanitization

The NanoMixer features an uncomplicated flush-to-clean mechanism.

The NanoMixer holds CE and RoHS certifications.

Applications

The NanoMixer is utilized for nanoparticle formulation across a range of applications:

- mRNA/DNA/siRNA delivery formulations

- Multi-component formulation development

- Nanoemulsions and fat emulsions

- Cell disruption

- Liposomes and lipid nanoparticles

- Nanoparticle suspensions

Specifications

Source: Genizer

|

| Catalog No. |

NanoMixer |

NanoMixer-Triplex |

NanoMixer-Quad |

| Flow Rate |

0-10 mL/min |

0-10 mL/min |

0-10 mL/min |

| Min. Sample |

1 mL |

1 mL |

10 mL |

| Max. Pressure |

500 psi

A+B=AB |

500 psi

A+B=AB+C=ABC |

500 psi

A+B=AB

A+B+C=ABC

A+B+C+D=ABCD |

| Dimensions (cm) |

70 × 36 × 30 |

70 × 36 × 30 |

70 × 36 × 30 |

| Weight |

20 kg (75 lbs) |

30 kg (75 lbs) |

35 kg (75 lbs) |

| Max. Temp. |

80 ºC (176 ºF) |

| Power |

110 V / 220 V |

| Cleaning |

Flush to clean |

| Application |

mRNA/DNA/siRNA delivery systems, Nano emulsion, fat emulsion, liposome, cell disruption, nano dispersion, microsphere |

| Features |

Digital display of pressure and flow rate |

| Standard Features |

| Channel |

Y-type Microfluidic Mixing Chip AB-Y; ABC-Y; ABCD-Y |

| Control System |

High-pressure programming control systems: touch screen, speed control, auto stop control by volume, time, pressure, or temperature, settable volume control as low as 0.2 mL, display of flow rate and time, overload protection |

| Pressure Gauge |

Digital display on the touch screen |

| Inlet Type |

Luer |

| Outlet Type |

Luer |

| Inlet Reservoir |

1 mL gas-tight syringe |

| Outlet Reservoir |

10 mL Tube |

| Product Material |

316L stainless steel, tungsten carbide, Viton, Teflon |

| Material Standard |

Sanitary grade, FDA, GMP |

| Warranty |

1 year against any manufacturing defects |

| Option Features |

| Control System |

Please send the drawing if you need a customized Microfluidic Chip |

| Detector |

Pressure gauge, pressure transducer, temperature transducer |

| Outlet type |

Tri-clamp or luer |

| Heat Exchanger |

Heating/cooling jacket with built-in temperature sensor |

| Inlet Reservoir |

2.5 mL, 5 mL, 10 mL gas-tight syringe |

| Outlet Reservoir |

2.5 mL, 5 mL, 10 mL, 50 mL, 100 mL tube or gas-tight syringe, S/S cylinder, jacketed glass cylinder or online |

| Cylinder |

Titanium high-pressure cylinder (resistant to strong acid and base) |