Dry Granulator and Tablet Coater for Indian Customer

L.B. Bohle experts successfully completed the Factory Acceptance Test (FAT) of a BRC Dry Granulator and a BTC Tablet Coater together with the customer.

India's pharmaceutical industry continues to grow steadily and is increasingly turning to innovative technologies to improve production efficiency and product quality. In this context, a leading Indian pharmaceutical company has chosen state-of-the-art equipment from

L.B. Bohle.

"The customer has already been using our equipment. Now we are pleased to supply them with an additional BRC Dry Granulator and a BTC Tablet Coater," says Burkhard Schmidt, Sales Director.

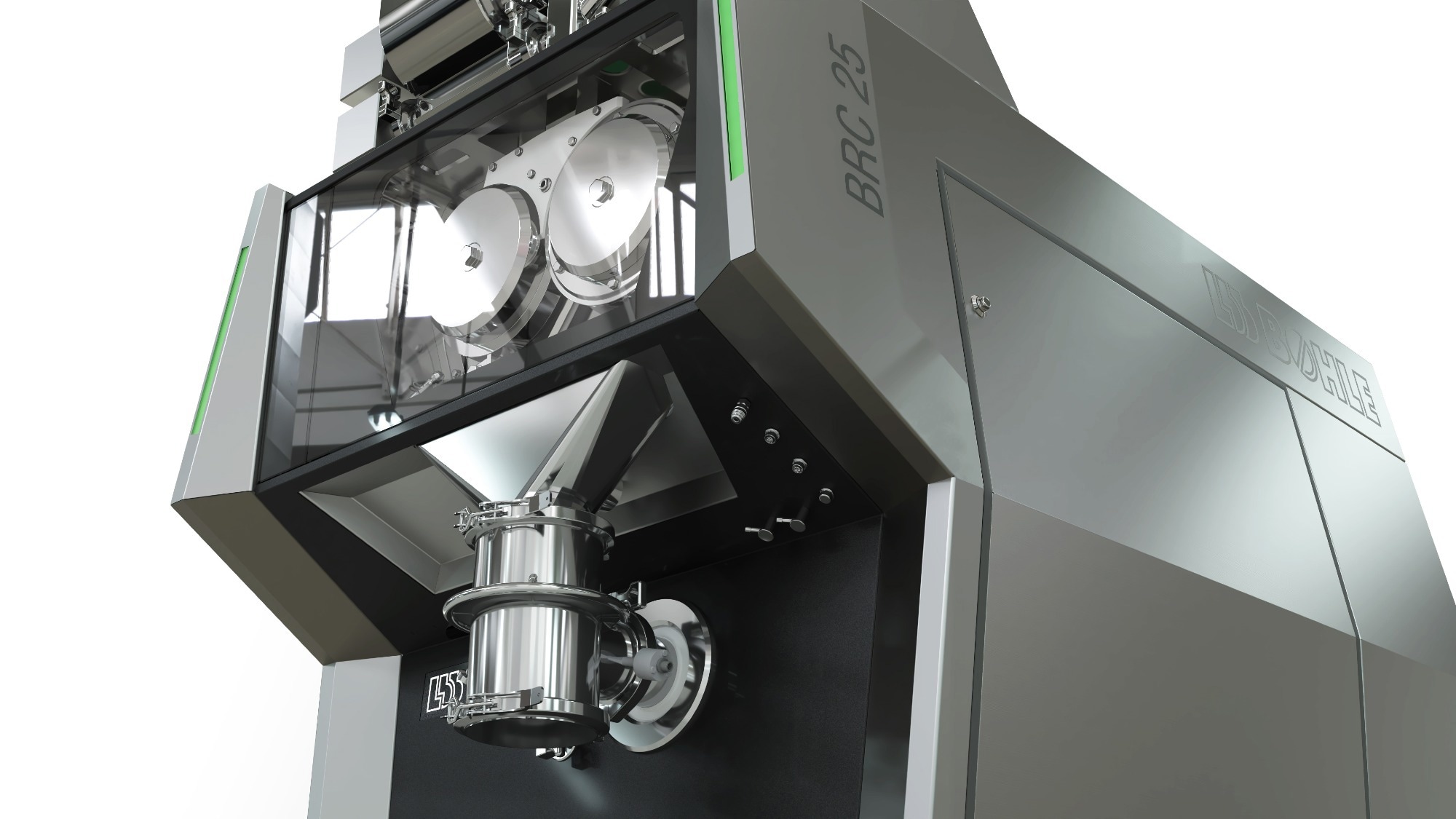

Image Credit: L.B. Bohle Maschinen und Verfahren GmbH

Strategic Choice for German Engineering

The decision to partner with L.B. Bohle was based on many years of successful cooperation and the company's innovative pharmaceutical process solutions.

"These machines will enable the Indian company to expand its production capacity while maintaining the highest quality standards. The focus is on efficient, reliable and cost-effective production of export-oriented pharmaceuticals," explains Schmidt.

Efficient Granulation with the BRC Dry Granulator

The BRC Dry Granulator offers a highly efficient granulation solution. Compared to wet granulation, dry granulation offers numerous advantages in terms of overall cost, energy consumption and environmental impact. It also enables seamless scale-up from development to commercial production in full compliance with cGMP requirements - all on the same machine.

Precise Coating with the BTC Tablet Coater

The BTC Tablet Coater ensures optimal and uniform coating of tablets. "The customer is already using L.B. Bohle coaters and is fully satisfied with their efficiency, productivity and coating uniformity," adds Schmidt. With the addition of the BTC 400, production capacity has been further increased.

Image Credit: L.B. Bohle Maschinen und Verfahren GmbH

Boosting Competitiveness in the Indian Market

By investing in L.B. Bohle machines, the Indian pharmaceutical company is committing itself to state-of-the-art process technology.

"These new systems will help the company meet the increasing market demands and establish itself as a leading manufacturer in the long term," explains Schmidt.

In a highly competitive market like India, it's crucial to continuously optimize processes and improve production efficiency. The integration of the BRC dry granulator and the BTC tablet coater will significantly increase productivity while ensuring consistently high product quality.

The decision to invest in pharmaceutical technology from L.B. Bohle underlines the importance of innovative solutions for competitive pharmaceutical manufacturing. L.B. Bohle is recognized worldwide as a trusted partner and established brand for state-of-the-art equipment that helps customers meet the highest quality standards.