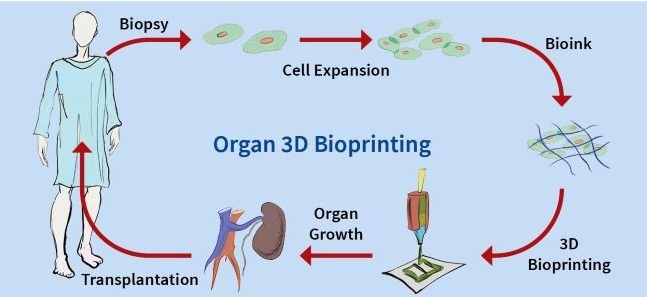

Organ transplantation represents a remarkable achievement in medical science. While some individuals gain from these procedures, countless others miss out on life-saving opportunities due to the lack of available donor organs.1 Developing functional organs in a laboratory using a patient's own cells could offer a tremendous benefit to humanity.

Image Credit: Gorodenkoff/Shutterstock.com

Creating complex human organs, however, presents substantial difficulties. For instance, human skin consists of various cell types, including keratinocytes, fibroblasts, and endothelial cells. To engineer an organ, it is crucial to culture these diverse cell types in an environment that mimics the conditions found within the human body.

3D bioprinting has immense potential because it can effectively replicate tissue structure and manage the tissue microenvironment. This technology provides high reproducibility in experiments, along with automation, scalability, and adaptability for commercial use.3

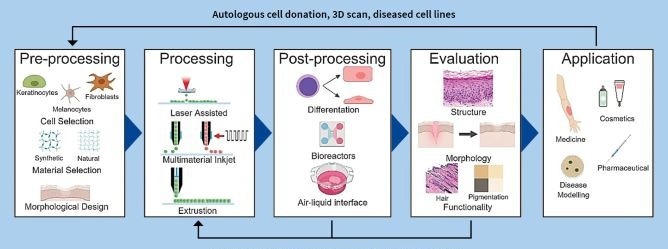

Figure 1. Step-wise process of 3D bioprinting.4 Image Credit: Himedia Laboratories Private Limited

This additive manufacturing method combines biomaterials and cells to produce functional tissues and organs. By mixing biomaterials with cells and growth factors, bioinks are created. These bioinks support cell growth and replicate the extracellular matrix due to their biocompatibility and adjustable physiochemical properties.

The 3D bioprinting process involves careful selection of cells and biomaterials. For example, rigid materials like polycaprolactone are chosen for bone, while softer materials such as gelatin and alginate are used for skin.

Both natural and synthetic polymers are utilized, characterized by their chemical composition, viscosity, mechanical strength, and compatibility. Bioinks can be printed using various techniques, including extrusion and inkjet printing. The resulting tissue constructs undergo culture and evaluation for their structural and functional characteristics.4-7

The global market for 3D bioprinting was valued at $1.3 billion in 2022 and is expected to grow to approximately $3.3 billion by 2027, reflecting a CAGR of 20.8%. Key factors driving this market include technological advancements, increasing applications in the pharmaceutical and cosmetic industries, and growing funding opportunities.8

Major players in this sector include Cellink (BICO Group), Allevi, Regenhu, and Poietis, all of which offer diverse 3D bioprinters and bioinks.9 HiMedia provides a range of cutting-edge products and services, including bioinks, organoid media, organoids, 3D bioprinted models, 3D bioprinters, characterization services, and skill development programs, to support research and innovation in tissue engineering, regenerative medicine, and cultivated meat in India.

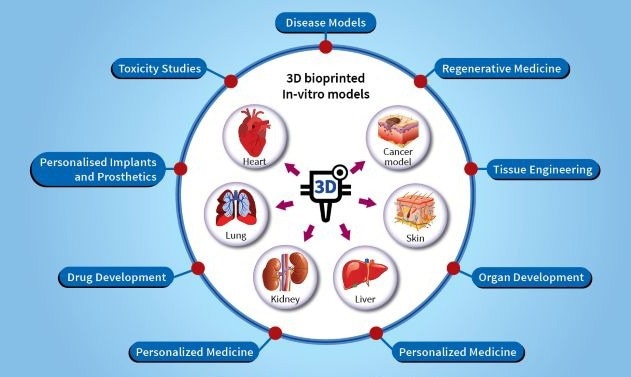

Figure 2. Applications of 3D bioprinting.10 Image Credit: Himedia Laboratories Private Limited

This expanding field has significant implications for tissue engineering, regenerative medicine, and drug development. For example, a blend of alginate, gelatin, and collagen has been utilized to create a liver lobule using hepatocytes and endothelial cells. This bioprinted liver lobule exhibited higher levels of albumin secretion, urea production, cytochrome P450 activity, and expression of biomarkers like albumin, MRP2, and CD31 compared to the non-bioengineered monolayer cultures.11,12

The AuriNovo™ implant, developed by 3DBio, is an autologous 3D bioprinted ear made from a patient’s own cells to address congenital defects. This approach significantly lowers the risk of graft rejection and related complications post-implantation, offering hope to many patients who endure long waits for organ donations and the associated challenges of immunosuppressive therapies.13

Due to their complexity and physiological relevance, 3D bioprinted models serve as reliable platforms for drug screening, potentially replacing animal testing in pharmaceutical and cosmetic research. These innovations will also aid in creating models of diseased organs, enhancing research into personalized medicine.14 The true power of 3D bioprinting will be realized when lab-engineered transplantable organs become a reality. HiMedia is proud to contribute to this evolving field to benefit the nation and the globe.

Figure 3. 3D bioprinting as a future modality to develop transplantable organs for clinical applications.15 Image Credit: Himedia Laboratories Private Limited

References and further reading

- Directorate General of Health Services, Government of India. National Organ Transplant Programme. Available at: https://dghs.gov.in/content/1353_3_NationalOrganTransplantProgramme.aspx

- Ayming UK. (2020). 3D bioprinting - The next step in tailor-made medicine. (online) Available at: https://www.ayming.co.uk/insights/opinion/3d-bioprinting-the-next-step-in-tailor-made-medicine/.

- Augustine, R., et al. (2021). 3D Bioprinted cancer models: Revolutionizing personalized cancer therapy. Translational Oncology, 14(4), p.101015. https://doi.org/10.1016/j.tranon.2021.101015.

- Loai S, et al. Clinical Perspectives on 3D Bioprinting Paradigms for Regenerative Medicine. (2019). Regenerative Medicine Frontiers. https://doi.org/10.20900/rmf20190004.

- Agarwal, S., et al. (2020). Current Developments in 3D Bioprinting for Tissue and Organ Regeneration–A Review. Frontiers in Mechanical Engineering, 6. https://doi.org/10.3389/fmech.2020.589171.

- Khalaf, A.T., et al. (2022). Bone Tissue Engineering through 3D Bioprinting of Bioceramic Scaffolds: A Review and Update. Life, 12(6), p.903. https://doi.org/10.3390/life12060903.

- Jiang, T., et al. (2019). Extrusion bioprinting of soft materials: An emerging technique for biological model fabrication. Applied Physics Reviews, 6(1), p.011310. https://doi.org/10.1063/1.5059393.

- Marketsandmarkets Research. 3D Bioprinting Market | Growing at a CAGR of 20.4% | MarketsandMarkets. (online) Available at: https://www.marketsandmarkets.com/Market-Reports/3d-bioprinting-market-170201787.html.

- grand view research (2019). 3D Bioprinting Market Size, Share | Industry Analysis Report, 2019-2026. (online) Grand View Research. Available at: https://www.grandviewresearch.com/industry-analysis/3d-bioprinting-market.

- Shibu Chameettachal, et al. (2019). 3D Bioprinting: Recent Trends and Challenges. Journal of the Indian Institute of Science, (online) 99(3), pp.375–403. Available at: https://journal.iisc.ac.in/index.php/iisc/article/view/4780 (Accessed 6 Jun. 2025).

- Ma, L., et al. (2020). Current Advances on 3D‐Bioprinted Liver Tissue Models. Advanced Healthcare Materials, 9(24), p.2001517. https://doi.org/10.1002/adhm.202001517.

- Kang, D., et al. (2020). Bioprinting of Multiscaled Hepatic Lobules within a Highly Vascularized Construct. Small (Weinheim an Der Bergstrasse, Germany), (online) 16(13), p.e1905505. https://doi.org/10.1002/smll.201905505.

- Business wire. (2022). 3DBio Therapeutics and the Microtia-Congenital Ear Deformity Institute Conduct Human Ear Reconstruction Using 3D-Bioprinted Living Tissue Implant in a First-in-Human Clinical Trial. (online) Available at: https://www.businesswire.com/news/home/20220602005051/en/3DBio-Therapeutics-and-the-Microtia-Congenital-Ear-Deformity-Institute-Conduct-Human-Ear-Reconstruction-Using-3D-Bioprinted-Living-Tissue-Implant-in-a-First-in-Human-Clinical-Trial.

- Mazzocchi, A., Soker, S. and Skardal, A. (2019). 3D bioprinting for high-throughput screening: Drug screening, disease modeling, and precision medicine applications. Applied Physics Reviews, 6(1), p.011302. https://doi.org/10.1063/1.5056188.

- Aurelien Forget and Dargaville, T. (2019). The next pharmaceutical revolution could be 3D bioprinted. (online) The Conversation. Available at: https://theconversation.com/the-next-pharmaceutical-revolution-could-be-3d-bioprinted-79676.

About Himedia Laboratories Private Limited

With a presence in more than 150 countries, HiMedia is amongst the top three brands in the Bioscience Industry.

HiMedia Laboratories Private Limited is world renowned for manufacturing high quality culture media for microbiology. Additionally, we provide advanced media and products in the fields of Molecular Biology, Cell Biology, Plant Tissue Culture, Chemicals and Lab Aids/Equipment. As a Top Tier Global player, we are not only dedicated towards products but also striven towards introducing technologies such as Genomics Sequencing Services and Hydroponics.

HiMedia has managed to do this over decades as we have our own in-house bulk raw materials manufacturing plant. This enables us to deliver consistent quality products that conform to ISO 9001:2015 and ISO 13485:2012 and WHO: GMP.

HiMedia Labs. caters to one of the broadest Biosciences product categories: our premier established line of Microbiology products and newer promising products in Molecular Biology, Automated and Molecular Instruments, Cell Biology, Chemicals, and Premium Grade Lab Consumables, amongst others. The COVID-19 pandemic revolutionized not the clinical industry’s thought process regarding the significance of Molecular Diagnostics products.

The ‘Molecular Biology and Virology Division’ of HiMedia Laboratories Pvt. Ltd. Also called as HiGenoMB® is a One Stop Solution Provider churning out potential Research and Industry oriented Molecular biology products for the past glorious decade. About 2000 different products such as Nucleic Acid Extraction and Amplification (PCR) Kits, Cloning Reagents, Buffers & Chemicals for proteomics studies, Automated Molecular Instrumentation including RT PCR machines and PCR thermal cyclers and DNA/RNA Extraction platforms are being produced. The Proficient researchers in this department are spear heading the challenging field of Molecular Diagnostics to provide a complete solution for clinical diagnosis, agriculture, veterinary sciences, food industry, drug discovery and forensic medicine with the use of Real Time PCR or quantitative PCR kits and thermal cyclers. Our Molecular Biology Division-has established an in-house Advanced Sequencing and Bioinformatics facility which marks HiMedia’s entry into the Services space.

Our Cell Biology segment contributes with technologies which have brought in Serum free media for biopharma applications, Viral Vaccine Production Platform, Multicompendial grade chemicals, cultivated meat, and 3D bioprinting.

Moving from conventional to advanced automated methods like MALDI-TOF (Autof MS 1000) has been our newest endeavour for Microbiology.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.