A cGMP piece of machinery, the MSRTM MicroSphere Refiner enables producers and drug developers to carry out a variety of aseptic procedures at different scales using their microspheres. This unique solution was created over many years using a Quality-by-Design (QbD) methodology, considering microspheres' properties and processes' behavior.

Polymeric microspheres have a reputation for being challenging for manufacturers to process because of their unique qualities, particularly when batch sizes progressively rise during the microsphere product development process. By analyzing these systemic industry challenges and gaining a deeper understanding of microsphere processes with end users in the field, the MSRTM MicroSphere Refiner's unique features were invented.

Download the Brochure for More Information

Features and benefits

An all-in-one solution

Drug producers can use the MSRTM MicroSphere Refiner, a piece of Current Good Manufacturing Practice (cGMP) equipment, to finish various aseptic processes with their microspheres at different scales. It maximizes product recovery, batch repeatability, and production flexibility by efficiently performing the following processes within a single system:

- Microsphere Discharge/Recovery

- Microspheres Classification/Filtration/De-watering

- Microsphere Sampling

- Microsphere Washing

- Microspheres Drying, including Freeze-Drying

Batch reproducibility – At the touch of a button

Image Credit: Powder Systems

The MSRTM MicroSphere Refiner is an automated system that eliminates the need for operators to handle products by hand during the production process. This reduces the possibility of human error while optimizing batch-to-batch reproducibility. At the push of a button, production can begin, and pre-planned process recipes can be followed.

Drug producers can pre-design and pre-load software process recipes with the necessary process parameters appropriate for their particular production using the PSL automation platform. This increases the speed and adaptability of their manufacturing processes.

PSL adheres to major international standards and regulations for software automation, including GAMP5 (Good Automated Manufacturing Practice, version 5 by ISPE) and 21 CFR Part 11, established by the US FDA for electronic records and signatures.

Download the Brochure for More Information

Product recovery – A crucial requirement

As microspheres are very expensive to develop and produce, pharmaceutical companies must maximize product recovery to maintain their competitiveness in the global market. This essential requirement was considered when designing the MSRTM system's core features.

The MSRTM MicroSphere Refiner's product recovery method is special because it is fully automated and eliminates the need for operators to manually off-load products through an aseptic isolator. The MSRTM method, an all-in-one solution, helps maximize product yield by minimizing the number of transfers and connections.

Production agility, delivered

A Good Manufacturing Practice (GMP) piece of equipment, the MSRTM is appropriate for applications involving multiple products. It enables end users to maintain their agility and quickly adjust to shifting production needs.

Source: Powder Systems

| Filtration Agility |

Drying Agility |

Cleaning Agility |

| One modular vessel design |

Positive temperature drying |

GMP design / no product traps |

| Quick filtration media change-over |

Freeze-drying |

CIP spray-ring option |

| Multi-zone filtration |

Multi-zone drying |

Suitable for potent product processing |

User process, PAT-verified

The US FDA promotes using Process Analytical Technology (PAT) in the pharmaceutical sector to guarantee improved product quality control and a faster time to market.

Drug manufacturers have embraced the PAT initiative because MSRTM technology enables them to monitor their microsphere product quality and integrity in real time during different stages of production, including filtration and drying processes (including lyophilization).

The integration of PAT reduces trial-and-error methods. This shortens the time it takes pharmaceutical companies to develop drugs for microspheres, which are typically more complex than conventional drugs and helps them move toward first-time correct manufacturing.

Image Credit: Powder Systems

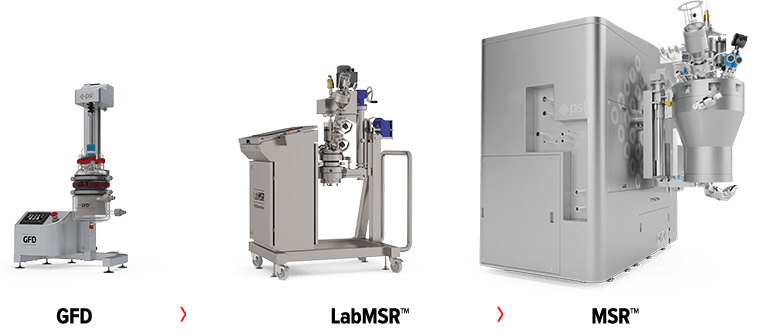

Successful scale-up

Image Credit: Powder Systems

For most drug manufacturers, large or small, developing complex drug formulations such as microsphere delivery systems has always been difficult. It is essential to ensure that the process technology selected for the R&D stage can be fully scaled to larger production batches. Drug makers may have to pay millions if they discover too late that a microsphere process is not scalable.

The MSRTM product line was created to make developing microsphere drugs more straightforward, starting from the preliminary R&D stages and moving through GLP batches, clinical trials, and commercial production. The solutions can guarantee important production parameters like filtration time, washing time, drying time, etc., and important process objectives like product yield, product quality, and integrity, batch consistency, etc., can be maintained at every scale.

Download the Brochure for More Information

Technical overview

Applications and options

Vessel sizes

Source: Powder Systems

| |

0.05 Model |

0.125 Model |

| Typical Product Cake Volume (process-dependent) |

1.25 – 8.7 L |

3.1 – 21.8 L |

| Maximum Liquid Volume |

98 L |

123 L |

| Equipment Dimensions (L x W x H) |

2,720 x 2,850 x 2,760 mm |

Upgrade options

Source: Powder Systems

| |

Standard MSR™ |

Upgrade Options |

| De-watering Method |

Suitable for Single Pass and Loop De-watering |

| Filtration Step(s) |

Single Filtration (Refiner) |

Dual Filtration (Scalper + Refiner) |

| Drying Method |

Suitable for Vacuum Drying and Freeze-Drying |