In industries where dry powder analysis is crucial - pharmaceuticals, cement manufacturing, additive manufacturing, and more - precision, speed, and flexibility are essential to keeping operations efficient and on track.

Yet most dry powder systems have remained bulky, stationary, and hard to adapt to fast-paced, dynamic environments.

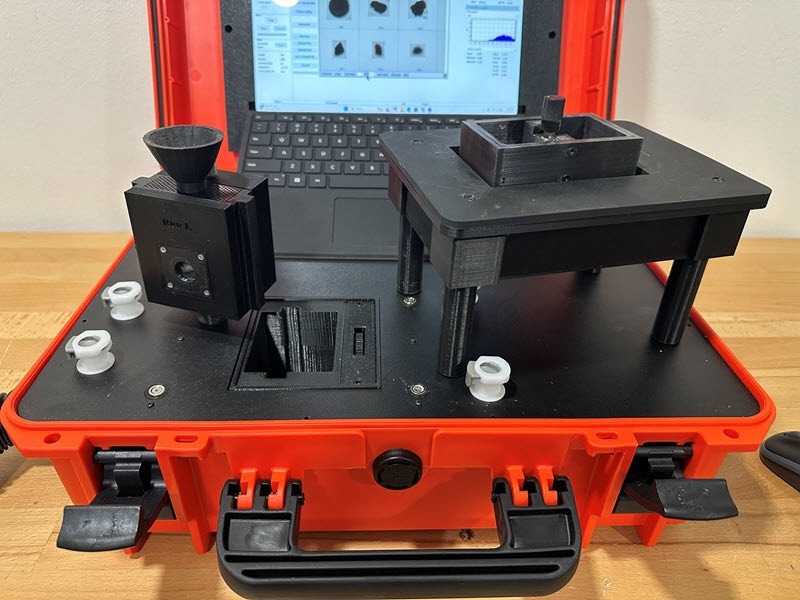

That’s where the Raptor Portable Dry Powder Analyzer comes in. It is the first system built specifically for portability, delivering lab-grade performance wherever it’s needed.

Why portability matters in dry powder analysis

Traditional dry powder systems require samples to be transported to a central lab - a process that introduces several drawbacks:

- Risk of sample contamination

- Loss of valuable time

- Disruptions to production efficiency

The Raptor Portable Dry Powder Analyzer eliminates these challenges by allowing engineers, operators, and quality teams to perform advanced powder analysis exactly where it’s needed - on the production floor, in clean rooms, or out in the field.

Key features of the Raptor portable dry powder analyzer

- Truly Portable: A lightweight, compact design that integrates seamlessly into existing workflows without disruption.

- High-Precision Measurement: Uses dynamic image analysis to deliver highly accurate particle size and shape data.

- Easy-to-use Interface and Tools: An intuitive dashboard enables fast, confident decision-making in the field - no expertise required.

- Versatile Application: Built to perform reliably across a wide range of powders, including pharmaceutical excipients, cement powders, specialty chemicals, and more.

- Rugged Design: Designed for mobility without compromising the durability needed for demanding industrial environments.

- Thumbnail Images: Visual snapshots provide clear, objective insight into your sample, making it easy to understand what’s happening in your process, even without technical training.

Dry Powder Module on Raptor Portable particle size and shape analyzer. Image Credit: Vision Analytical Incorporated

Industries that will benefit

- Pharmaceutical industry: Perform real-time analysis of active ingredients and excipients - without ever leaving the cleanroom or production area.

- Cement and construction materials: Monitor particle size distribution and material consistency directly on-site to maintain quality and fine-tune formulations.

- Chemical manufacturing: Analyze specialty powders in-line, without disrupting production or risking sample contamination.

- Advanced manufacturing and 3D printing: Ensure optimal powder characteristics for powder bed fusion and other additive processes, right at the point of use.

Setting a new standard

With the Raptor Portable Dry Powder Analyzer, Vision Analytical Incorporated is setting a new standard for what’s possible in powder analysis. It’s more than just a tool - it’s a driver of faster insights, improved quality, and greater flexibility in how and where you work.

Whether you're focused on pharmaceutical quality control, high-performance cement production, or cutting-edge additive manufacturing, the Raptor gives you the power to analyze faster, smarter, and wherever it’s needed most.

Raptor Portable Analyzer: Dry Powder Module Demonstration for Particle Analysis

Video Credit: Vision Analytical Incorporated