Every Gems product has engineering excellence at its cornerstone. This is received by customers in the form of a highly robust, well-designed solution with extended service life. But what happens when a larger-scale OEM application requires a solution that’s more “out of the box” than “off the shelf”?

What happens if a custom solution from another manufacturer is already designed and implemented, but does not meet expectations? What if a new custom solution is required in a short timeframe, but the legacy supplier, or technology, is obsolete? Gems custom engineering services provide solutions to these problems for many qualified OEMs.

Building Partnerships Decreases Risk

A poorly selected customization partner is a costly and time-consuming venture for any OEM, with losses realized in a variety of ways. For example, the partner may lack the inhouse resources required for rapid response. This can lead to hidden costs and delays. Alternatively, a partner might show a lack of experience in the required technology or application.

This can ultimately lead to improper technology integration and unplanned design revisions. Matters can be further complicated by the fact that designed-in components can be very costly to design out. This is especially the case when the component has already been produced at OEM volumes and specified into the bill of materials.

The Gems engineering team has the remarkable talent of being able to effectively optimize legacy sensor design-ins. This is particularly important in cases where specific constraints exist as a result of pre-determined conditions, such as space, available connectors, or measurement ranges, but in which, there is also a need for significant technology upgrades.

In all cases, Gems combines best practices in global design, lean manufacturing and procurement with proven engineering excellence. This proven formula results in effective solutions to practically any measurement challenge. As a result, every Gems product can be custom designed, manufactured and implemented at OEM volumes, with significantly shorter lead times than many off-the-shelf options in industry.

Building a Foundation That Lasts

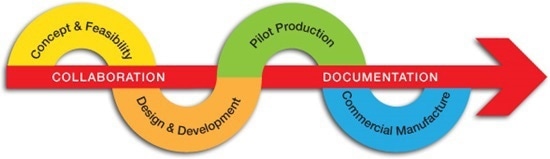

Qualified OEMs opting for custom engineering services from Gems immediately receive a wealth of expertise in hands-on product design, systems integration, development, and customization. This includes a team that is well-versed in designs that need to be tightly integrated, or work in complex legacy footprints.

For OEM customers, this means that all aspects of design, as well as prototyping, revisions, manufacturing and testing, in addition to complete support for the bill of materials (BOM), are managed by one cohesive, cross-functional team. This also includes strategic sourcing of components in order to improve reliability, streamline costs and reduce the time-to-market.

It can also include expanded manufacturing efficiency of sensors, to include production in multiple countries at the same time, improving logistics and lead times. Working in partnership with Gems, customers can expect full transparency as well as regular briefings. Customers can also expect to be well-informed on all available possibilities and options, to allow informed decision making. This customer-centered approach forms a vital cornerstone for collaborative success in the future.

Using Smart Engineering to Reduce Costs

Gems continually invests in the ongoing education of its in-house engineering team as part of its unwavering commitment to R&D and product quality. Company-wide training ensures that all of Gems engineers are highly competent. The intensity of this training ensures that a custom collaboration will always include well-informed decision-making on a technical level.

All of Gems engineers are trained to work smart; if the design of a sensor can be streamlined or simplified, they will find a way to improve it. This ingenuity inspires Gems to regularly evolve its standard catalog products in order to address a wide breadth of measurement challenges. In addition, it leads to the project time being reduced, and cost savings being identified.

Rapid Prototyping and Design Engineering

Experienced engineers can spot potential challenges for a given application early on, at the drawing stage. Their expertise can help to solve inherent design flaws prior to the first prototype sensor being made. Gems engineers regularly work with customer-supplied or original drawings in order to verify dimensional data, connectors, tolerances, and mounting configurations, as well as to ensure that the overall BOM is supported.

Gems incorporates the strategic sourcing of highly reliable components at the lowest price points. Failure Mode and Effect Analysis (FMEA) can also be employed as a means to evaluate new sensor design performance systematically.

These methods can help to identify, minimize and ultimately prevent potential failure modes of a given sensor prior to its full-scale production. Combining effective product designs and rapid prototyping, accelerated sensor customization can be achieved. Gems can generally fabricate samples of custom solutions that are test-ready within two weeks.

These samples allow in-application testing of the form, fit and function of a custom sensor design with a view to the rigors of its intended installation environment to be carried out. In addition, it allows for design refinements before production at full-scale OEM volume. Making any changes necessary at the prototype stage allows manufacturing costs and lead times to be fully optimized.

Creating an Integrated Environment for Problem-Solving

Gems internal operations are structured as an integrated, multidisciplinary problem-solving team. This cohesive group is made up of world experts in the design and development of sensors, spanning engineering, sales, global sourcing, testing, production planning, and operations. From the earliest point of consultation, Gems engineering team takes part in the data collection and evaluation of custom OEM volume product manufacturing needs.

Typical data points can include application details, intended volumes, performance requirements, and target cost points. In addition, Gems engineers evaluate existing customer solutions for their overall application suitability and performance. This collected data helps customers to determine whether alternative technologies might help to improve performance or reduce costs.

Sourcing Quality Components

Gems strategic sourcing teams focus on achieving continuous quality improvements in component supplier reliability and quality. This includes pre-screening specified BOM components using design reviews, evaluations of overall supplier performance, and routine audits of suppliers.

Gems global sourcing personnel become involved at the earliest stages of product design in order to ensure the shortest possible lead times. The best suppliers, components and pricing are rapidly identified, as is the availability of required components for immediate OEM volume manufacturing upon receipt of customer design approval.

Streamlining Product Manufacturability

Gems engineers work to continuously streamline the manufacturability of all of Gems products. Company-wide goals include yield improvements, reducing inventory requirements, reducing production cycles and lowering costs. To help achieve this, dedicated manufacturing cells are created for each custom sensor project.

These cells encompass all of the production steps required for proactive assessments, and corrections of potential failure modes. All of the global manufacturing operations are driven by lean manufacturing principles. Gems maintains co-located ISO 9001 certified manufacturing facilities in Europe, Asia, and North America.

Each of these has the required state-of-the-art equipment to simultaneously address every area of design, sourcing, and manufacturing. For customers developing medical, semiconductor, or other sensing technologies which have stringent quality and anti-contamination requirements, Gems maintains specially designated facilities.

Each of these includes the infrastructure necessary to ensure strict and full compliance with global regulatory standards. The final custom manufacturing of all of Gems products can be provided using the facility most local to the customer. This allows transportation and logistics costs, as well as lead times, to be reduced.

Gems global manufacturing base allows it to provide complete assembly, labeling and packaging support for both small-and large-quantity OEM volumes. Regardless of location, the consistency of manufactured product quality is guaranteed.

Building Efficiencies with Dedicated Equipment

In the case of qualified OEM customers with larger-scale production requirements, Gems can extend equipment sourcing benefits. This can include sharing of dedicated capital equipment and tooling machinery at any of Gems global manufacturing sites.

In providing this service, customers can receive unprecedented access to state-of-the-art manufacturing resources across their layout strategies. Combining critical tooling and manufacturing layouts, production can be optimized by both Gems and the customer. This shared access to critical production infrastructure increases end product consistency and quality, while ensuring ongoing maintenance schedules are adhered to.

Product Testing and Validation

Gems validates and tests all of its products in order to ensure that published specifications are met or exceeded. Depending upon intended market end use, Gems can also validate products to specific standards, for example, SAE or MIL-spec. GEMS can also conduct fatigue and durability testing over extended life cycles, within higher humidity environments, or at higher temperatures.

By conducting this extensive testing in the same location as its design and manufacturing operations, Gems can address any required process revisions that might otherwise delay final OEM volume production.

About Gems Sensors and Controls

For 60 years, Gems Sensors & Controls has designed and manufactured a broad range of liquid level, flow and pressure sensors, switches, miniature solenoid valves, and preassembled fluidic systems. Gems is a division of Danaher Corporation, a Fortune 500 company with global presence.

To ensure rapid customer response, the company manufactures its products via three, fully equipped ISO certified facilities located in North America, Europe, and Asia, shipping over 4 million sensors annually. These facilities are further supported by a number of local sales, engineering and service offices.

Find out why leading OEMs, including John Deere, National Oil Well Varco, Abbott Laboratories, Lockheed Martin, GE Transportation, and many others have placed their trust in Gems.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.