A polymer is composed of many repeating macromolecule units, known as monomers. These monomers can bond covalently in various dimensions, forming 3D, 2D, or 1D structures. The term was introduced by Berzelius in 1833. Most polymers in use today were synthesized after the 1840s, with the molecular structure only understood after Staudinger’s work in 1922.

Image Credit: Nemes Laszlo/Shutterstock.com

Globally, about 140 million tons of synthetic polymers are produced annually. These polymers are highly stable and resistant to biodegradation, negatively impacting the environment since their recycling often involves combustion or incineration. The recycling process is inefficient, leading to overflowing landfills. These processes emit carbon dioxide (CO2) and carbon monoxide (CO), contributing to climate change.

A significant issue is the generation of microplastics (MPs), which are tiny plastic fragments (1−5000 μm). Humans encounter MPs daily through air, water, and food (especially seafood) due to wanton and careless usage and disposal of plastics.

Microplastics also affect birds and animals. Various MP types are ingested by humans, causing gastrointestinal absorption, physical harm, and chemical toxicity. MPs have been found in bodily fluids like blood, raising concerns about health issues, including cancer.

Research continues on the chronic effects of MPs on the human body. Undigested MPs are excreted from living creatures, leading to bioaccumulation in the environment and food chains. Humans, at the top of the food chain, are particularly affected.

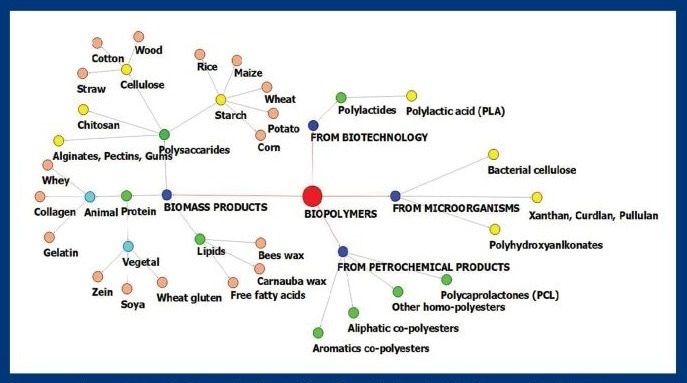

Figure 1. Types of polymers showing a wide variety of biodegradable and conventional polymers and their respective sources2. Image Credit: Himedia Laboratories Private Limited

Developing alternative bio-based materials is urgently needed. The current situation must be addressed due to environmental, public, and scientific interests in biopolymers, which share desirable properties with conventional synthetic polymers.

Biopolymers are derived from living organisms, unlike synthetic materials created by humans. They are readily found in nature or extracted from plants, animals, and algae.

Common biopolymers include agar and alginates from red algae of the genus Gelidium or various brown algae referred to as seaweeds. Another common biopolymer is derived from hyaluronic acid taken from newborns' umbilical cords.

Some biopolymers arise from fermentation, such as polysaccharides that occur intracellularly or extracellularly in microbes. Notable polysaccharide-based biopolymers include guar gum, curdle gum, and xanthan gum.

Types and sources of biopolymers

Biopolymers, or biodegradable, renewable polymers, have garnered renewed interest. Their primary advantage lies in biodegradability, facilitated by microorganisms like bacteria, fungi, and algae. Biopolymers vary in type and source, as illustrated in Figure 1.

Gellan gum (GG)—A novel biopolymer

Gellan gum (GG) is an anionic, linear polysaccharide produced through the fermentation of Sphingomonas elodea. It has gained significant attention due to its diverse applications in food, medicine, cosmetics, edible packaging, agriculture, and pharmaceuticals.

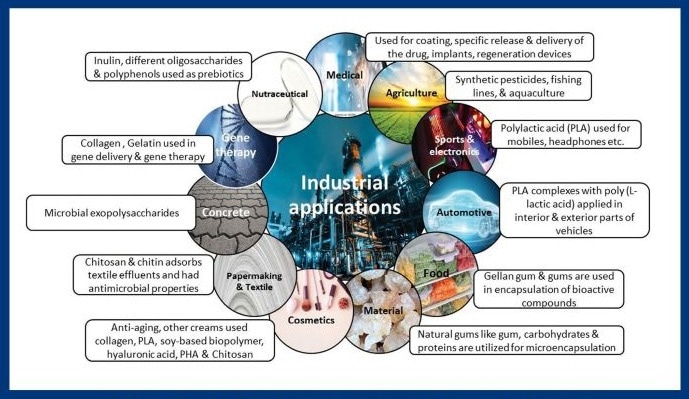

Figure 2. Various industrial applications of different biopolymers based on their properties. Image Credit: Himedia Laboratories Private Limited

Its monomers include glucose, glucuronic acid, and rhamnose. GG exhibits properties similar to or better than xanthan gum and alginate, including water solubility, easy bio-fabrication, effective film formation, biodegradability, and biocompatibility.

Its gelling properties vary with acyl group levels: low-acyl GG produces stiff gels, while high-acyl GG yields soft, elastic gels. GG remains relatively unexplored in biomedical applications, with limited studies on its use in tissue engineering.

Common applications of GG

- In the food industry, GG is an emulsifier, stabilizer, binder, gelling agent, coagulant, lubricant, film former, and thickener. The USFDA has approved its use in food products.

- GG is also an agar substitute for microbiological media, enhancing clarity and reducing toxicity.

- It is used in humans for ocular drug delivery.

Given its potential, further research on innovative GG applications is ongoing. Currently, GG is imported, leading to supply chain issues and higher costs. Hence, GG production and development should occur in India to reduce dependency. HiMedia is initiating in-house GG production and developing a modified (granulated) form to improve dispersion in microbiological media and other uses.

Properties and applications of biopolymers

Biopolymers possess physical and chemical properties akin to synthetic polymers but also have unique characteristics, such as low cost availability, biodegradability, and reduced toxicity. These characteristics lead to extensive applications across various fields. Different biopolymers offer diverse properties, facilitating applications in multiple industries, as shown in Figure 2.

Demand and market growth of biopolymers

Biopolymers are increasingly favored as replacements for petroleum-derived materials in the food and healthcare industries. Resource scarcity and growing environmental awareness have spurred global biopolymer growth. Enhanced properties of these biopolymers significantly support their practical applications.

The biodegradable plastics market is projected to reach $6.12 billion by 2023. According to the Markets and Markets annual report, the biopolymer market is expected to grow to $26.3 billion by 2027, with a CAGR of 11.1% from 2022-2027. Europe currently dominates the biopolymer market, holding 43.5% share, followed by North America and Asia Pacific, while the rest of the world comprises only 7.5%.

Recent developments

The biopolymer sector is a research hotspot due to high-value applications. Interdisciplinary studies on biopolymers will address complex health and wellness issues. Numerous biopolymer types are being developed for expanding applications. Recent developments include:

- A team from IASST created a smart biodegradable biopolymer nanocomposite film that detects humidity, allowing food freshness to be monitored with UV light.

- In August 2022, DSM Engineering Materials launched StanylB-MB, containing up to 100% bio-based material.

- In June 2022, a German polymer manufacturer introduced Verdessence™ RiceTouch, a new biopolymer for personal care products.

- UK startup SoluBlue offers a natural polymer from FDA-approved seaweed, ideal for food packaging as it absorbs moisture and prevents mold, extending shelf life.

Future and scope of biopolymers

Cost-effective, high-performance biopolymers are essential for industrial applications. Therefore, exploring and identifying new natural sources is critical for replacing hazardous synthetic polymers. However, biopolymers face challenges like low tensile strength and low electrical and thermal conductivity. Merging biopolymers with natural fibers can create stronger composites, requiring further study for eco-friendly designs. These must be evaluated for their biodegradability, recyclability, and effect against several environmental factors.

Biodegradable materials can alleviate environmental problems compared to synthetic packaging. The plastics industry aims to enhance biodegradability without sacrificing strength.

Conclusion

Ongoing advancements in biotechnology research and development have significantly broadened the applications of biopolymers, spanning everything from everyday goods to high-tech industries.

Biopolymers are promising in the medical field due to their biocompatible and biodegradable nature. As research progresses, these materials could reshape modern medicine.

The development and refinement of biopolymers is expected to steadily increase, making it essential to streamline their commercialization for consistent progress—especially in comparison to synthetic polymers. With ongoing investigations into the properties of new biopolymer compounds, aligning production and development costs with those of traditional materials remains a critical step for broader adoption.

One of the main challenges facing the commercialization of new biopolymers is competition from established or advanced synthetic polymers, particularly when it comes to development and production costs.

Thanks to their versatility, biopolymers are among the most adaptable materials across various industries. Continued research into their performance and life-cycle impact will help expand their applicability.

With sustained and focused R&D, biopolymers could gradually replace conventional synthetic polymers, offering a more sustainable and less polluting alternative.

References

- Prajapati, V.D., et al. (2013). An insight into the emerging exopolysaccharide gellan gum as a novel polymer. Carbohydrate Polymers, 93(2), pp.670–678. https://doi.org/10.1016/j.carbpol.2013.01.030.

- Gheorghita, R., et al. (2021). Applications of Biopolymers for Drugs and Probiotics Delivery. Polymers, 13(16), p.2729. https://doi.org/10.3390/polym13162729.

- Hishamuddin, Norsyakirah Izzati; Razali, Mohd Hasmizam; and Mat Amin, Khairul Anuar. (2022). Application of Gellan Gum Biopolymer in Biomedical Applications: A Review. Makara Journal of Science, 26(1). https://doi.org/10.7454/mss.v26i1.1271.

- Verbeek, C. ed., (2012). Products and Applications of Biopolymers. InTech. https://doi.org/10.5772/1802.

- Yesudass, S. (2020). Biopolymers-Applications in Various Fields: A Mini Review. Polymer Science: Peer Review Journal, 1(3). https://doi.org/10.31031/psprj.2020.01.000514.

- Thomas S, Gopi S, Amalraj A. Biopolymers and Their Industrial Applications: From Plant, Animal, and Marine Sources, to Functional Products. 1st ed. Elsevier; 2021.

- IndustryARC. Biopolymers Market Report, 2022-2027. (online) Available at: https://www.industryarc.com/Report/11739/biopolymers-market.html.

- Parker, L. (2023). Microplastics are in our bodies. How much do they harm us? (online) National Geographic. Available at: https://www.nationalgeographic.com/environment/article/microplastics-are-in-our-bodies-how-much-do-they-harm-us.

- Lim, X.Z. (2021). Microplastics are everywhere — but are they harmful? Nature, 593(7857), pp.22–25. https://doi.org/10.1038/d41586-021-01143-3.

- McArdle, R. and Hamill, R. (2011). Utilisation of hydrocolloids in processed meat systems. Processed Meats, pp.243–269. https://doi.org/10.1533/9780857092946.2.243.

- Asghar, A., et al. (2023). Food gels: Gelling process and new applications. Advances in Food Rheology and Its Applications, pp.365–384. https://doi.org/10.1016/b978-0-12-823983-4.00002-9.

- Aaliya, B., Sunooj, K.V. and Lackner, M. (2021). Biopolymer composites: a review. International Journal of Biobased Plastics, 3(1), pp.40–84. https://doi.org/10.1080/24759651.2021.1881214.

- PlasticsToday. (2020). Present and Future Trends in Biodegradable Polymers. (online) Available at: https://www.plasticstoday.com/biopolymers/present-and-future-trends-biodegradable-polymers.

About Himedia Laboratories Private Limited

With a presence in more than 150 countries, HiMedia is amongst the top three brands in the Bioscience Industry.

HiMedia Laboratories Private Limited is world renowned for manufacturing high quality culture media for microbiology. Additionally, we provide advanced media and products in the fields of Molecular Biology, Cell Biology, Plant Tissue Culture, Chemicals and Lab Aids/Equipment. As a Top Tier Global player, we are not only dedicated towards products but also striven towards introducing technologies such as Genomics Sequencing Services and Hydroponics.

HiMedia has managed to do this over decades as we have our own in-house bulk raw materials manufacturing plant. This enables us to deliver consistent quality products that conform to ISO 9001:2015 and ISO 13485:2012 and WHO: GMP.

HiMedia Labs. caters to one of the broadest Biosciences product categories: our premier established line of Microbiology products and newer promising products in Molecular Biology, Automated and Molecular Instruments, Cell Biology, Chemicals, and Premium Grade Lab Consumables, amongst others. The COVID-19 pandemic revolutionized not the clinical industry’s thought process regarding the significance of Molecular Diagnostics products.

The ‘Molecular Biology and Virology Division’ of HiMedia Laboratories Pvt. Ltd. Also called as HiGenoMB® is a One Stop Solution Provider churning out potential Research and Industry oriented Molecular biology products for the past glorious decade. About 2000 different products such as Nucleic Acid Extraction and Amplification (PCR) Kits, Cloning Reagents, Buffers & Chemicals for proteomics studies, Automated Molecular Instrumentation including RT PCR machines and PCR thermal cyclers and DNA/RNA Extraction platforms are being produced. The Proficient researchers in this department are spear heading the challenging field of Molecular Diagnostics to provide a complete solution for clinical diagnosis, agriculture, veterinary sciences, food industry, drug discovery and forensic medicine with the use of Real Time PCR or quantitative PCR kits and thermal cyclers. Our Molecular Biology Division-has established an in-house Advanced Sequencing and Bioinformatics facility which marks HiMedia’s entry into the Services space.

Our Cell Biology segment contributes with technologies which have brought in Serum free media for biopharma applications, Viral Vaccine Production Platform, Multicompendial grade chemicals, cultivated meat, and 3D bioprinting.

Moving from conventional to advanced automated methods like MALDI-TOF (Autof MS 1000) has been our newest endeavour for Microbiology.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.