Sponsored Content by TecanReviewed by Olivia FrostFeb 9 2026

From powering artificial intelligence models to maintaining reproducibility across sites, modern laboratories are demanding more than precision alone: They require reliability, adaptability, and confidence in their data.

Hal Wehrenberg Vice President of Digital Transformation. Image Credit: Tecan

This is precisely where Tecan Trading envisions the future of automation.

With nearly twenty years in the field, Hal Wehrenberg, Vice President of Digital Transformation at Tecan, has played a pivotal role in steering the evolution of lab automation from engineering-centric systems to researcher-focused solutions.

According to him, “What really matters is whether your team can understand the interface, adjust methods, troubleshoot issues, and keep things running without constantly relying on external support.”

This article examines how liquid handling automation is evolving to meet the demands of new scientific and operational requirements. Why do intuitive design, system adaptability, and user experience now hold equal importance to pipetting accuracy?

The constant priority: Data quality and reproducibility

Throughout Wehrenberg’s two decades in automation, one principle has remained unwavering: data quality. Whether supporting clinical research or developing proprietary AI models, consistent and accurate data remain the foundation of every laboratory’s success.

Manual handling, Wehrenberg explains, inevitably introduces human error – especially when working with miniaturized assays on 384- or 1536-well plates. By contrast, automation safeguards precision and ensures that today’s assays are comparable to those performed last week or even last year.

Scalability is equally important. Many researchers are generating increasing volumes of data each year, but human capacity has limits. Instruments that can operate continuously, across variable conditions, and without fatigue, enable throughput to expand exponentially while maintaining consistency.

Rising complexity and the demand for smarter design

The laboratory landscape has become more complex, with scientists now managing multiple instruments and digital systems simultaneously. In earlier years, automation was primarily within the domain of engineers.

Today, researchers and technicians often operate as many as fourteen different software interfaces daily, ranging from automation control to LIMS, ELNs, and scheduling platforms.

Researchers today often manage complex workflows across multiple platforms. Simpler interfaces help them get it right. Image Credit: Tecan

Wehrenberg notes that this has shifted the focus of design. “When the people pressing ‘Go’ are provided with straightforward interfaces, it is not just about convenience. It ensures that processes are executed correctly and compliantly,” he explains.

Simplified design, therefore, directly contributes to reliability, safety, and data integrity.

Usability: The cornerstone of effective automation

For laboratories adopting automation for the first time, usability should be a primary consideration. According to Wehrenberg, teams must “feel at home” with their instruments. While technical specifications often attract the most attention, day-to-day operability is what defines long-term value.

He advises laboratories to experience live demonstrations or, ideally, test the software themselves. If a vendor requires an expert to operate the system during a demo or discourages direct interaction, that may reveal more than specifications ever could.

When automation isn’t accessible, it becomes a bottleneck. Intuitive interfaces help research teams stay self-sufficient. Image Credit: Tecan

The real value, he emphasizes, lies in whether a team can independently adjust methods, identify errors, and sustain operations with confidence.

Designing interfaces that reduce cognitive load

An effective user interface, Wehrenberg says, must serve multiple operators with varying levels of expertise. In many laboratories, several users share the same instrument, and new personnel are routinely trained. This makes clarity and simplicity essential.

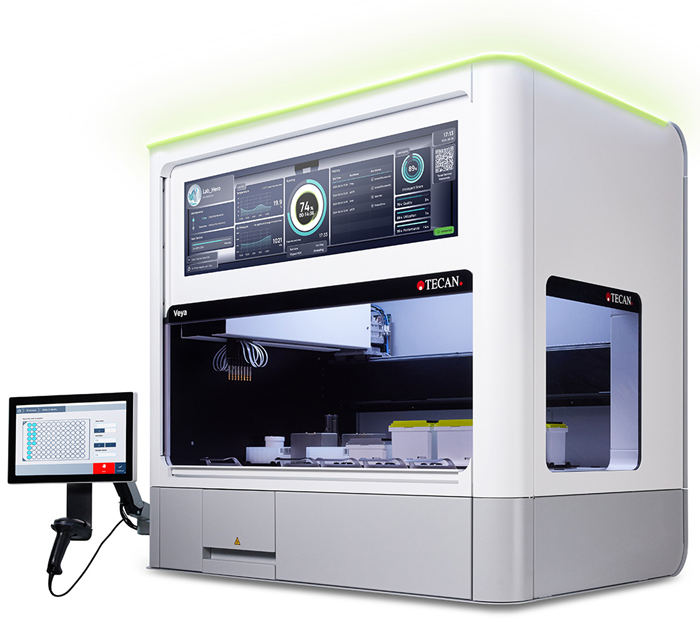

Tecan’s latest liquid handling system, Veya®, exemplifies this philosophy. The system includes a distinct status light that provides instant visual feedback on instrument activity.

Its OneView™ dashboard functions like a vehicle’s control panel, displaying system performance, recent runs, and maintenance schedules at a glance. The intuitive touchscreen guides users through methods in a clear, customizable, and visual format.

OneView provides real-time visibility into instrument status, performance, and environment. Image Credit: Tecan

Wehrenberg contrasts this with traditional SOP binders, which users often abandon after a few weeks. By embedding instructions directly within the interface, Veya reduces dependence on memory, minimizes error potential, and enhances reproducibility across users.

Supporting compliance through thoughtful interaction design

In regulated environments, even small interface choices can influence compliance and audit outcomes.

One example within Veya is the confirmation mode on the touchscreen: the “Next” and “Confirm” buttons are placed separately, compelling users to pause and acknowledge each instruction before proceeding.

Veya includes a wraparound status light and an intuitive touchscreen interface for guided operation. Image Credit: Tecan

This design encourages deliberate interaction, whether confirming that a vacuum pump has been activated or samples have been scanned, and automatically records every step. Such logs create a complete trace of who performed each action and when, providing valuable transparency for both compliance audits and troubleshooting.

Engineering consistency: Smarter hardware for variable conditions

Hardware innovation plays an equally important role in maintaining accuracy across varying environments. Veya incorporates Air Restriction Pipetting (ARP) technology, which allows volumes from 1.0 µl to 5.0 ml to be handled using a single arm without hardware changes, an uncommon capability in the market.

Traditional systems often require separate modules for different volume ranges, increasing calibration points and potential error sources. In contrast, Veya’s integrated sensors continuously monitor air pressure and temperature, automatically compensating for environmental fluctuations such as altitude or humidity.

Complementing this is Pressure-Monitored Pipetting (PMP AI), a neural network–driven system that monitors every aspiration, detects anomalies such as clots or blockages, and responds in real time. This ensures that errors are identified immediately rather than after an entire batch is compromised.

Veya’s smart pipetting combines ARP and PMP AI for precise, reliable liquid handling across volumes, conditions and sites. Image Credit: Tecan

AI-driven data integrity: A new expectation

As laboratories generate data to train AI-driven discovery models, the emphasis has shifted from mechanical precision to long-term data trust. “The question is no longer whether we can pipette accurately,” says Wehrenberg. “It is whether we can rely on the data across time, across instruments, and across sites.”

Automation, in his view, is essential to maintaining this level of reproducibility. Beyond technical performance, instruments must facilitate structured, traceable data flow between systems – enabling seamless input and output with AI models, analytical software, and other instruments within the workflow.

Choosing the right platform: Flexibility and future-readiness

When evaluating automation systems, laboratories should seek solutions that not only meet their current requirements but also scale with future needs. Tecan’s Veya Suites embody this philosophy by combining predefined scripts, optimized layouts, and adaptable configurations.

Your needs may change. Veya is designed to evolve with them - flexible, adaptable and ready for what’s next. Image Credit: Tecan

Research environments evolve rapidly: new sequencing kits, assay formats, and workflows emerge regularly. Systems must therefore allow operators to modify protocols without waiting for vendor intervention. Compatibility with third-party devices, such as heaters or shakers, further ensures operational flexibility.

Wehrenberg encourages decision-makers to consider their roadmap carefully: “Some laboratories know exactly what they will run for the next decade, while others, especially in drug discovery, must stay agile. Choosing a one-purpose system limits your ability to adapt.”

The future of liquid handling: Integration over isolation

Looking ahead, Wehrenberg believes that automation’s true value lies in integration rather than raw performance.

“Most modern assays already fall well within the technical capabilities of liquid handling systems,” he notes. “What matters now is how data flows, connects, and maintains integrity over time.”

As data increasingly underpins AI-driven innovation, its provenance and consistency are paramount. Automation platforms must therefore support interoperability, accommodate diverse users, and ensure that every result can be trusted.

For Tecan, this focus on usability and digital integration is not new; it reflects the company’s ongoing mission to build systems that empower scientists, streamline workflows, and advance the pursuit of reliable data.

The future of automation will be shaped by the need for both quality and connectivity across end-to-end lab workflows. Image Credit: Tecan

Veya: Tecan’s next-generation solution for liquid handling automation

Image Credit: Tecan

Developed for scientists seeking more from their automation systems, Veya offers:

- Effortless throughput: Run more samples with minimal manual intervention

- Consistent results: Reproducibility across users, sites, and time

- Smart simplicity: Intuitive touchscreen interface and customizable workflows

- Rapid setup: Veya Suites provides predefined scripts and optimized layouts

- Built-in intelligence: Real-time pipetting feedback and continuous process monitoring

- Future-ready integration: Seamless connection with existing systems and evolving protocols.

From the first day of installation, Veya delivers the performance, usability, and adaptability that define effortless automation.

About Hal Wehrenberg

Hal Wehrenberg is the Vice President of Digital Transformation at Tecan Trading. With nearly two decades of experience in laboratory automation, his expertise spans service, product development, and strategic leadership.

He has played a key role in the development of Tecan’s liquid handling software and now leads initiatives to integrate advanced digital technologies into Tecan’s life science and clinical laboratory solutions.

About Tecan

Tecan is a leading global provider of automated laboratory instruments and solutions. Its systems and components help people working in clinical diagnostics, basic and translational research, and drug discovery bring their science to life.

In particular, the company develops, produces, markets, and supports automated workflow solutions that empower laboratories to achieve more. Its Cavro-branded instrument components are chosen by leading instrumentation suppliers across multiple disciplines.

Tecan works side by side with a range of clients, including diagnostic laboratories, pharmaceutical and biotechnology companies and university research centers. Its expertise extends to developing and manufacturing OEM instruments and components, marketed by its partner companies. Whatever the project – large or small, simple or complex – helping its clients to achieve their goals comes first.

The company holds a leading position in all the sectors it works in, and has changed the way things are done in research and development labs around the world. In diagnostics, for instance, it has raised the bar when it comes to the reproducibility and throughput of testing.

In under four decades, Tecan has grown from a Swiss family business to a brand that is well established on the global stage of life sciences. From pioneering days on a farm to the leading role the business assumes today, Tecan empowers research, diagnostics and many applied markets around the world.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.