In the biopharmaceuticals sector, engineers have to precisely regulate the gases utilized in bioreactors to improve microbial growth and assure accurate mixing and distribution of biomass.

Moreover, precision burner control is required to create bottles, vials, and glass ampules that are used to package the resulting biopharmaceuticals properly.

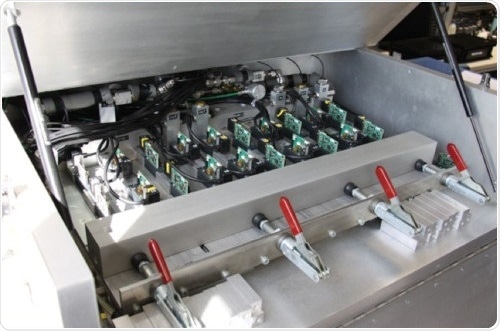

Image Credit: Sierra Instruments

The RedySmart™ is different from other competitive systems since it offers high reliability, excellent physics, and unprecedented flexibility. In addition, the RedySmart™ thermal mass flow meters and controllers are micro-electro-mechanical system (MEMS)-based technology specifically developed to complement the SmartTrak® capillary-based mass flow meters and controllers available from Sierra Instruments.

The RedySmart™ thermal mass flow devices are not affected by pressure fluctuations and upstream temperature, and do not contain any moving parts. These features lead to excellent repeatability and accuracy.

The RedySmart™ offers a true OEM mass flow control solution to customers, thanks to its modular design, versatile digital communications options (Modbus included without any additional charge), cabling system, and effortless incorporation into a gas mixing block.

Lifetime No-Drift Sensor Warranty

Sierra Instruments offers lifetime no-drift sensor warranty because the RedySmart™ employs high-precision MEMS (Micro-Electro Mechanical Systems) technology using a state-of-the-art, ultra-stable no-drift complementary metal-oxide semiconductor (CMOS) sensor.

In addition, the MEMS no-drift sensor warranty provides a huge competitive benefit in OEM applications, where it is important to have long-term stability. Sierra Instruments defines no-drift as less than 1% of full scale across the lifespan of the instrument.

This means, if a drift of greater than 1% of full scale takes place over the sensor’s lifetime, the sensor and/or the whole instrument will be replaced or repaired, and recalibrated without any additional charge.

Using MEMS methods, both mechanical devices and electronic circuits can be produced on a silicon chip, just like the process employed for built-in circuits.

Product Benefits

- MEMS-based technology with ultra-stable no-drift CMOS sensor

- Lifetime no-drift sensor warranty — in the case of drift, the instrument will be either replaced or repaired without any extra cost

- Modular-customized to meet customers’ requirements — the communication and power cable system can be effortlessly connected, providing ultimate flexibility

- Optimized for OEM applications — ideal for burner control/biopharmaceuticals

- Integrated display — totalizer, units, mass flow and set point

- Precision valve — through a precision electromagnetic control valve, the valve seat assumes the accurate height above the valve orifice needed to sustain a flow to the set point

- Rapid set point control — response times are as fast as +/–80 ms

- Human and Systems Interface — local display readout; enables in-field configuration

- Communications (human and system interface) — an available local display readout communicates important flow data, while a free software app allows in-field configuration of each device

- NIST-traceable, advanced calibration — all units are calibrated across their entire flow range by utilizing real gas to ensure repeatability and precision across the device’s lifetime

Specifications

- Precision of +/–1.0% of full scale

- Repeatability of +/–0.2% of full scale

- High accuracy of up to ±0.3% of full scale ±0.5% of reading

- O2, N2, and air are standard; other non-corrosive and non-toxic gases are provided on request

- Pressure of 3–160 psia (0.2–11 bara)

- Flow ranges between 0 and 500 slpm (nlpm)

- Gas/ambient temperature 32 °F–122 °F (0 °C–50 °C)

- CE approved

- All devices include a digital Modbus RTU and analog interface, as standard

- 24 Vdc (18–30 Vdc), but 15 Vdc is also available on request

- Response time — controller (GSC): ±500 ms (3), and meter (GSM): ±80 ms (3)

The Ultimate OEM/MFC Lifetime No-Drift Sensor Warranty

- Ultimate OEM MFC — modular and small footprint with an easy-to-connect power cable communication system

- Competitive OEM pricing — low-cost solution

- Precision electromagnetic valve control

- Direct mass flow with thermal technology — pressure or temperature compensation is not included

- MEMS sensor stability — lifetime no-drift sensor warranty

RedySmart Meter. Image Credit: Sierra Instruments

RedySmart Modular Design. Image Credit: Sierra Instruments

RedySmart Industrial Ethernet. Image Credit: Sierra Instruments

RedySmart Digital Communications. Image Credit: Sierra Instruments

Precision Control Valve. Image Credit: Sierra Instruments

RedySmart in OEM Bioreactor Application. Image Credit: Sierra Instruments

RedySmart in Gas Mixing System. Image Credit: Sierra Instruments

MEMS Sensor- No Drift Guarantee. Image Credit: Sierra Instruments

Calibration System. Image Credit: Sierra Instruments

Thermal Mass Flow Meters & Controllers for BioPharm OEMs. Image Credit: Sierra Instruments