The Xevo TQ-S micro offers outstanding analytical versatility and great performance per square inch from the naturally reliable Xevo line of tandem quadrupole instruments. Discover how the Xevo TQ-S micro, which was created with your quantitative analysis and sample throughput in mind, can help the lab produce high-quality analytical data, injection after injection, in accordance with your accreditation, quality, and regulatory criteria.

Reliable instrument functioning provides exceptional sensitivity for such a small device and maximizes laboratory efficiency.

Xevo TQ-S micro visor. Image Credit: Waters Corporation

Specifications

System hardware specifications. Source: Waters Corporation

| . |

. |

| API sources and ionization modes |

High-performance ZSpray dual-orthogonal API sources:

1) Multi-mode source – tool-free ESI/APCI/ESCi™* (standard)

NB – Dedicated APCI requires an additional probe (optional)

2) UniSpray™ ion source (optional)

3) Tool-free APCI probe (optional)

4) nanoFlow™ ESI source* (optional)

5) ASAP* (optional)

6) APGC ion source* (optional)

7) ionKey™/MS™ source* (optional)

Optimized gas flow dynamics for efficient ESI desolvation

Tool-free source exchange

Vacuum isolation valve

Tool-free access to customer serviceable elements

Plug-and-play probes

De-clustering cone gas

Software control of gas flows and heating elements |

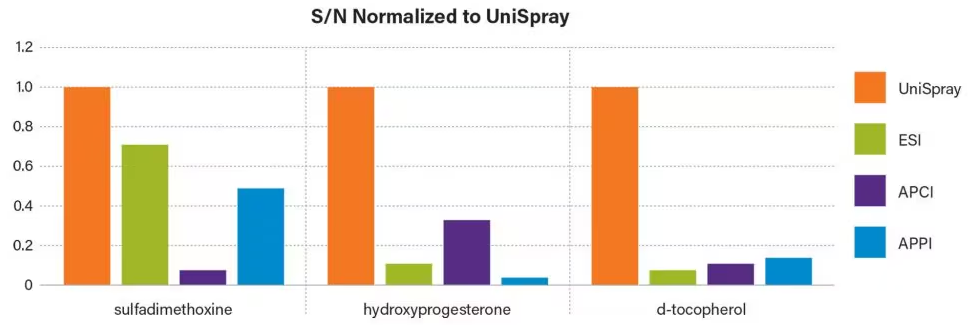

| UniSpray ion source option |

UniSpray is an ionization technique designed to broaden the scope of compounds that can be analyzed in a single run, including those that typically optimize in ESI, APCI, or APPI. Enhanced ionization efficiency and desolvation allow the potential to combine several methodologies into one, or simply enable the operator to keep the same source for multiple methods, requiring less time performing set-up and routine maintenance, and more time delivering results. |

| Ion source transfer optics |

StepWave ion transfer optics delivering class-leading UPLC™-MS/MS sensitivity. The unique off-axis design dramatically increases the efficiency of ion transfer from the ion source to the quadrupole MS analyzer at the same time as actively eliminating undesirable neutral contaminants. |

| Mass analyzer |

Two high-resolution, high-stability quadrupole analyzers (MS1/MS2), plus pre-filters to maximize resolution and transmission while preventing contamination of the main analyzers |

| Collision cell |

T-Wave™ enabled for optimal MS/MS performance at high data acquisition rates |

| Detector |

Low noise, off-axis, long-life photomultiplier detector |

| Vacuum system |

One split-flow air-cooled vacuum turbomolecular pump evacuates the source and analyzer

One vacuum backing pump |

| Dimensions |

Width: 35.6 cm (14 in)

Height: 60 cm (23.6 in)

Depth: 93 cm (36.6 in) |

| Regulatory approvals/marks |

CE, CB, NRTL (CAN/US), RCM |

System software specifications. Source: Waters Corporation

| . |

. |

| Software |

Systems supported on waters_connect and MassLynx™ version 4.2 or later |

| System setup and method development |

System parameter checking and alerts

Integrated sample/calibrant delivery system + programmable divert valve

Automated mass calibration

Automated sample tuning

Automated MRM method development

UPLC-MS/MS System Check – automated on-column performance test |

Automated MRM scheduling

(acquisition window assignment) |

Dwell time, inter-channel delay time, and inter-scan delay time for individual channels in a multiple MRM experiment can be automatically assigned (using the Auto-Dwell feature) to ensure that the optimal number of MRM data points per chromatographic peak is acquired. The Auto-Dwell feature can dynamically optimize MRM cycle times to accommodate retention time windows that either partially or completely overlap. This greatly simplifies MRM method creation, irrespective of the number of compounds in a single assay, while at the same time ensuring the very best quantitative performance for every experiment. |

| waters_connect Software |

The waters_connect Software provides a modern user experience with a HUB design and apps that provide a consistent connected user experience across all applications. It is built for applications with convenient access to scientific apps, allowing accelerated time-to-results and result quality. There are common utilities that complete the end-to-end workflow and help increase productivity and efficiency. Confidently report results with accurate, reliable, regulation-standard data from application-focused quantitative workflows with built-in traceability for utmost integrity. |

Performance capabilities. Source: Waters Corporation

| . |

. |

| Acquisition modes |

Full scan MS

Product ion scan

Precursor ion scan

Constant neutral loss

Multiple reaction monitoring (MRM)

Simultaneous full scan and MRM (RADAR) |

| RADAR |

An information-rich acquisition approach that allows you to collect highly specific quantitative data for target compounds while providing the ability to visualize all other components |

| Mass range |

2 to 2048 m/z |

Overview

- Reliable performance: Reach goals in full while providing operational performance that users can rely

- Maximize uptime: Make the most of the device and steer clear of lengthy repair visits

- Achieve more with less: Increasing productivity helps the lab reach its full potential. Boost the capacity and analytical capabilities while preserving the desired bench space

- Optimum productivity with flexible software options: With the versatile quantitation software solutions, the waters_connect and MassLynx software platforms, users can have the utmost flexibility in selecting the best solution for the lab

- Flexibility to meet analytical needs: To increase the analytical capacity and satisfy changing demands, alter the ionization sources or chromatographic inlets

Recommended Use: Laboratory workhorse that provides unparalleled flexibility to address evolving, expanding, or unforeseen analytical demands while providing the finest value performance per square inch of benchspace.

Reliable performance

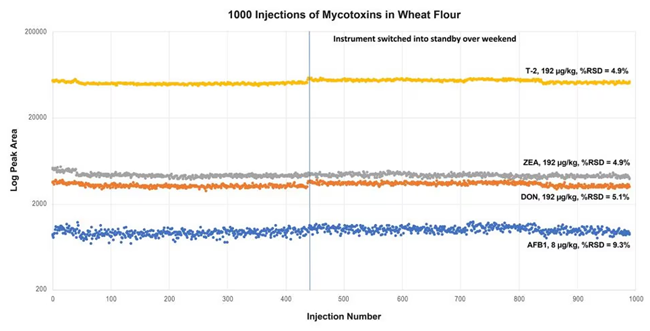

Reach the objectives in full with reliable operational performance. With 1,000 injections and a 5-9% relative standard deviation (RSD) for peak areas, a Xevo TQ-S micro research that examined mycotoxins in wheat flour—a complex matrix that can contaminate LC-MS equipment—showed steady performance over five days of continuous operation.

Image Credit: Waters Corporation

Maximize uptime

Make the most of the instrument and avoid lengthy repair trips. On average, customers who use the Xevo TQ-S micro won’t require an unscheduled service visit for three years after the warranty expires.

Make sure the lab operates effectively and is prepared to take advantage of future opportunities with Waters’ comprehensive analytical solutions with expert training (APS) and adaptable and affordable ways to grow the company through trade-ins, system service (FlexCHOICE), and technology advancements (FlexUP).

Xevo TQ-S micro tandem quadrupole mass spectrometer. Image Credit: Waters Corporation

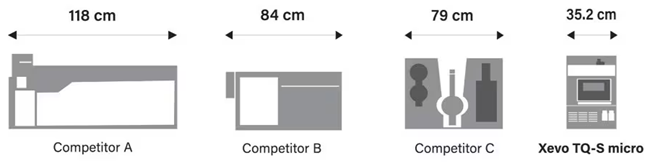

Achieve more with less

The Xevo TQ-S micro is 2-3 times narrower, which lowers the overhead expenses associated with laboratory space. Compared to comparable devices in its class, the Xevo TQ-S micro can reduce energy power consumption and related heat production by up to 34%.

With benchspace at a premium, choose an instrument designed to maximize performance per square inch. Image Credit: Waters Corporation

Ensure optimum productivity with flexible software options

With the versatile quantitation software solutions, the waters_connect and MassLynx software platforms, users can have the utmost flexibility in selecting the best solution for the lab.

The Exception Focused Review (XFR) feature, which may save up to 50% of your data review time and guarantee the lab is as productive as possible, is one of the efficiency and usability advantages of the cutting-edge, app-based software platform waters_connect. In the meantime, the tried, well-established MassLynx software package offers exceptional adaptability and flexibility in every application domain.

Convert data into meaningful results with waters_connect and MassLynx. Image Credit: Waters Corporation

Flexibility to meet the analytical needs

With the most often used atmospheric pressure ionization source of ESI as the standard, simply adjust the chromatographic input or ionization source to increase analytical capacity and meet changing needs.

UPLC/MRM data on Xevo TQ-XS with UniSpray ion source showing improved sensitivity for three compounds that would typically require a change in ionization technique for optimal analysis. Image Credit: Waters Corporation