Sponsored Content by LabmanReviewed by Maria OsipovaNov 3 2025

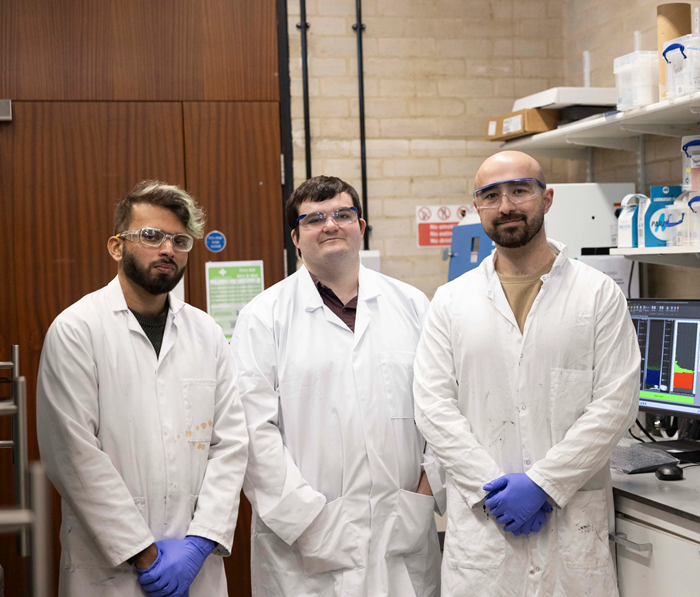

Using TIDAS, the Energy Materials Group at the University of Birmingham has increased productivity in fabricating electrode coatings and cells.

Image Credit: Labman

Challenge

The Energy Materials Group at the University of Birmingham required a probe of agglomerate size to support their fabrication studies. Determining agglomerate size in battery electrode slurries poses a significant challenge due to their high opacity. This opacity limits light scattering techniques, which usually require heavy dilution of the slurry, potentially affecting its structure.

Solution

Labman’s TIDAS provides the research team with an early measure of agglomerate size within the slurry. This is especially advantageous as it prevents the trialing of uncoatable slurries during battery manufacturing and delivers valuable insights into particle dispersion levels. Poorly dispersed slurries can restrict cell capacity and battery lifespan.

Results

TIDAS has enhanced efficiency for The Energy Materials Group, providing a key tool to objectively characterize battery electrode slurries at early production stages. This prevents hours, or even days of wasted time trialing unsuitable slurries and systematically records data for exceptional traceability.

Introduction

At the University of Birmingham’s School of Metallurgy and Materials, scientists are investigating the complete lifecycle of battery materials, from raw material sourcing and selection to manufacturing, performance, and end-of-life recycling. Within this cycle, manufacturing studies play a critical role.

A persistent obstacle involves ensuring slurry mixtures are of high quality, a factor fundamental to effective electrode coating and consistent battery performance. The high opacity of these slurries makes agglomerate size measurement especially challenging when using traditional methods.

Historically, the research team has relied on the manual Hegman gauge test to evaluate slurry quality. However, this approach suffered from poor reproducibility and subjective interpretation of results. Because the slurries are opaque, results were highly inconsistent between users. Meaningful data extraction was restricted to visual breakthrough points, an inadequate metric for research-grade quality control.

To support their manufacturing research, the team required an agglomerate-size probe. TIDAS is the only instrument on the market capable of reproducibly taking readings from completely opaque samples through dark field illumination techniques, thus enhancing the team’s suite of slurry characterization metrology.

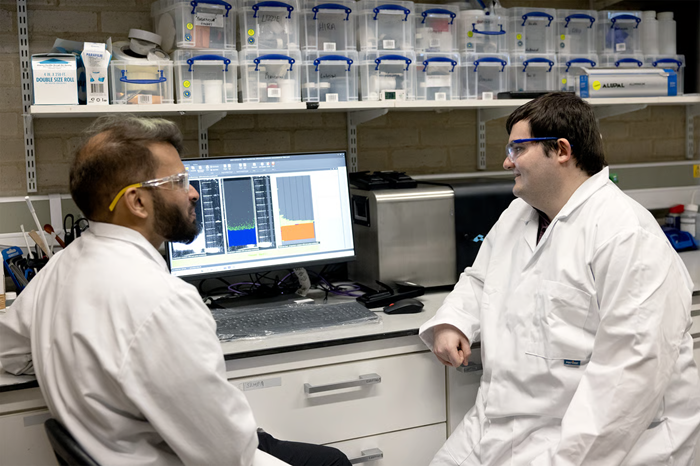

Image Credit: Labman

Saving time and resources

The TIDAS system provides an early indication of whether a slurry is suitable for coating and sufficiently well-dispersed to prevent later issues, such as reduced cell capacity. Since its implementation, the system has delivered substantial time and material savings.

Early detection of an uncoatable slurry (where particle size is too large for calendaring) saves approximately one hour in wasted coating trials. However, the most significant advantage comes from early identification of poorly dispersed slurries where particles are not mixed well or contain agglomerates.

If a slurry that has agglomeration issues is detected early, this saves us up to two hours coating, three hours cell making, and then testing. During testing, issues can take up to one week to show up, so TIDAS prevents significant time wastage.

Carl Reynolds, Researcher, University of Birmingham

In addition to time savings, the laboratory benefits from reduced material waste, preventing unnecessary use of foils, cell casings, and electrolytes. The system also frees up equipment and researcher time by preventing repeat experiments.

Real-world impact

The TIDAS system has proven particularly advantageous across various ongoing research areas. In trials investigating water-based biopolymer binders in electrode formulations, the system provides a critical first check on slurry consistency before full testing begins.

It has also allowed scientists to confidently work on 3D-printed electrode coatings, where the slurry's agglomerate size must be smaller than the nozzle opening to avoid blockages. In addition, TIDAS has strengthened the group’s contribution to the Faraday Institution’s NEXTRODE project, supporting novel metrology for advanced electrode production.

Labman have been great to work with. We’ve used the system for several months with no downtime. Any issues we’ve had were quickly resolved. Harry has been especially helpful, even visiting our lab to assist with troubleshooting.

Image Credit: Labman

Looking forward, the research team recognizes the vast potential of this approach in industry. The ability to measure and trace slurry quality early in the production process could reduce waste during the setup of commercial coating lines. Moreover, it can help manufacturers adopt novel technologies more efficiently by addressing dispersion issues before they escalate.

About Labman

About Labman

Labman is a global leader in creating custom automated laboratory technologies, products, and software that empower and advance scientific discovery. We collaborate across diverse industries, including medical, pharmaceutical, agritech, paints and coatings, and FMCG, to deliver innovative solutions. From our state-of-the-art manufacturing facilities, Labman’s multi-disciplinary teams design, build, and support systems used worldwide, enabling groundbreaking science in leading laboratories every day.

Labman in 2025

Video Credit: Labman

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.