In this interview, News Medical speaks with Guillaume Bentzinger, Project Manager at Novalix; Luis Carrillo, Managing Director at De Dietrich France; Philippe Robin CEO of Alysophil; and Alejandro Bara-Estaún, Solution Product Manager at Bruker about how flow chemistry, artificial intelligence (AI), and nuclear magnetic resonance (NMR) are being integrated to transform the production of active pharmaceutical ingredients (APIs).

Can you please introduce yourself and your role in the PiPAC project?

Guillaume Bentzinger: I’m a Project Manager at Novalix in the Flow & Process department, with a background in medicinal chemistry.

My role in the PIPAc project is to develop and optimize the synthetic routes for producing APIs under continuous flow conditions with focus on fentanyl and propofol.

What was the driving motivation behind the PIPAc initiative?

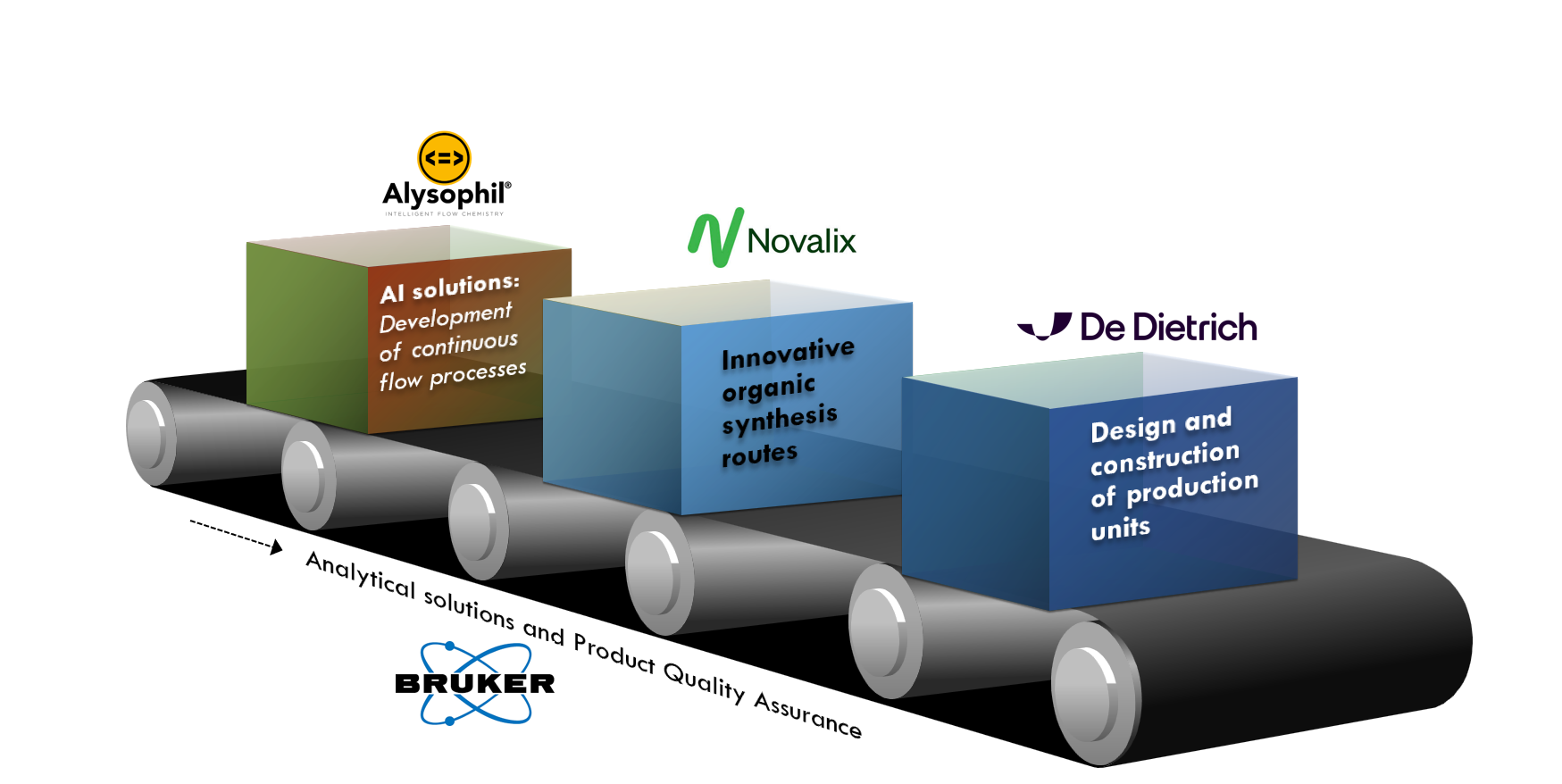

Guillaume Bentzinger: PIPAc stands for “Smart Production of APIs” in French. The initiative came about in response to the shortages highlighted during the COVID-19 pandemic. Our goal was to develop autonomous, continuous-flow systems that could relocate essential API production towards France and Europe. We formed a consortium of four partners, including Novalix, Alysophil, Bruker, and De Dietrich. They each contributed specialized expertise, from synthesis to analytics and automation.

Watch the full webinar

What specific challenges did you encounter during the synthesis of propofol and fentanyl?

Guillaume Bentzinger: For propofol, one major challenge was working with sulfuric acid in flow systems where we had to ensure compatibility with pumps and materials. Another challenge was the stability and solubility of starting materials in solution and in the reaction conditions. We also experimented with heterogeneous acid catalysis. The results were encouraging but the conversion and the selectivity towards propofol were not sufficient. For this reason, we decided to focus on the synthesis of fentanyl.

For fentanyl, we explored both conventional and novel synthesis routes. We obtained interesting results for both strategies but for time and industrial plan size reasons, we decided to focus only on the last step for the final industrial demonstrator. One constraint was working under regulatory constraints, which required us to build a restricted-area facility and initially explore non-regulated intermediates. Another was to find conditions avoiding precipitations in order to run the synthesis under flow conditions.

Image Credit: Novalix

How did De Dietrich approach scaling up the lab flow chemistry processes into a functional industrial demonstrator unit?

Luis Carrillo: Our role was to translate lab-scale chemical processes into a working demonstration unit. This involved conventional process engineering steps:

- Feasibility study

- Process definition

- Basic and detailed engineering

- Final construction

The challenge was combining a regulated pharma environment, ATEX compliance, and new continuous flow chemistry processes, all within a 15-square-meter lab footprint.

Can you tell us more about the 3D-printed flow reactor and its development?

Luis Carrillo: We partnered with FLONOAdditive to design and fabricate stainless steel reactors using metal additive manufacturing. The reactors were engineered via CFD and finite element simulations, ensuring accurate flow dynamics and heat transfer. The demonstrator includes two reactors that operate with a 50-minute residence time at 80 °C and 6 bar at optimal conditions. The reactor design allows easy cartridge swapping to adjust residence times.

How did De Dietrich ensure the successful integration of AI and process automation?

Luis Carrillo: A key challenge was enabling seamless communication between systems from different partners – Bruker’s synTQ platform, Alysophil’s AI engine, and our control systems.

We implemented a market-standard OPC UA communication protocol. Siemens PCS 7 managed the control architecture, with WinCC for supervision. Our instrumentation streams real-time data, coming from advanced NMR analytics and AI use to adapt process parameters, fully automated workflows in line with Pharma 4.0 principles.

Could you explain how Alysophil applied AI to optimize API production in this project?

Philippe Robin: We use deep reinforcement learning to train AI agents that can interpret real-time data from the process, such as temperature, pressure, and NMR readings, and take corrective actions. These agents are trained using a digital twin of the system, simulating hundreds of runs. The selected agents are then deployed to control flow rates autonomously, react to deviations, and even anticipate future trends in yield or conversion.

What makes this AI system different from traditional process control methods?

Philippe Robin: Traditional control relies on fixed recipes and operator oversight. Our AI reacts to deviations and predicts them. For example, if there is a drop in temperature, conditions can be adjusted before there is any impact on yield. It continuously learns from new data and improves over time, making the process more robust, adaptive, and autonomous. This level of predictive correction is relatively new and very promising.

What do you envision for the future of flow chemistry and AI integration in pharmaceutical manufacturing?

Philippe Robin: The future leans toward smarter, more autonomous production. AI combined with flow chemistry offers unmatched precision and scalability. With real-time analytics from NMR and automated control, we can enhance efficiency, minimize waste, and respond more quickly to supply chain disruptions. This is especially relevant for essential APIs, where global demand and reliability are critical.

Image Credit: Bruker BioSpin Group

How do you see the role of in-line NMR evolving further in combination with continuous-flow chemistry and AI for API production?

Alejandro Bara-Estaún: In-line NMR plays a crucial role in making flow chemistry processes more robust, traceable, and controllable. With instruments like the Fourier 80 integrated into orchestration PAT softwares like synTQ, we can measure the concentration of products like fentanyl and also track conversion, yield, and concentration in real-time.

The advantage of NMR lies in its inherent quantitative nature, providing concentration information proportional to the peak area, and its multi-attribute capability. With a single experiment, we can quantify multiple analytes simultaneously, achieving excellent resolution without sample destruction. Combined with AI, this enables a self-regulating, predictive manufacturing environment where quality and performance are consistently maintained without the need for constant manual oversight.

As this technology matures, I believe we'll see in-line NMR becoming the cornerstone of Pharma 4.0 facilities.

What were the key integration challenges you faced when connecting the benchtop NMR system with the flow reactor and AI architecture, and how were they overcome?

Alejandro Bara-Estaún: One challenge was making sure the data from the NMR was effectively transmitted to both the control system and the AI. We addressed this by integrating the Fourier 80 NMR system directly into the PAT orchestration software, synTQ. Through synTQ, we were able to push quantitative NMR data directly to the AI layer, enabling real-time decision-making. We also had to ensure temperature control of the flow cell using heated capillaries, as stability in flow chemistry is vital. Collaborating closely with the other partners, especially De Dietrich and Alysophil, helped overcome these challenges and ensured smooth data and process communication across the entire architect.

Watch the full webinar

About the speakers

Guillaume Bentzinger is a Project Manager at Novalix, where he leads synthetic chemistry development in Process Chemistry. He holds a PhD in medicinal chemistry from the University of Amiens (Université de Picardie Jules Verne) and conducted postdoctoral research at Almac Discovery and Queen’s University Belfast. His expertise spans both academic and industrial research, with a focus on continuous flow chemistry and scalable synthesis, mainly for pharmaceuticals.

Luis Carrillo is the Managing Director of De Dietrich Process Systems France. He holds a chemistry degree from the University of Barcelona and an executive MBA from IESE Business School. With over a decade of experience in chemical engineering and process systems, he specializes in designing and implementing industrial-scale solutions for regulated sectors like pharmaceuticals and fine chemicals.

Philippe Robin is the CEO and Co-Founder of Alysophil, a company that merges AI with chemical process control to enable autonomous manufacturing. A graduate of Chimie ParisTech (formerly ENSCP), he has more than ten years of experience in sustainable chemical production and innovation. At Alysophil, he has led multiple projects focused on real-time optimization of flow chemistry using artificial intelligence.

Alejandro Bara-Estaún is the Solution Product Manager for (bio)Process and Process Analytical Technology within Bruker BioSpin. He obtained his Ph.D. in Inorganic Chemistry at the University of Bath (UK) in collaboration with Bristol University and Evonik (Germany). He then undertook a two-year postdoctoral position at Bruker, leading the PIPAc project in collaboration with Alysohpil, Novalix, and De Dietrich.

About Bruker BioSpin Group

The Bruker BioSpin Group designs, manufactures, and distributes advanced scientific instruments based on magnetic resonance and preclinical imaging technologies. These include our industry-leading NMR and EPR spectrometers, as well as imaging systems utilizing MRI, PET, SPECT, CT, Optical and MPI modalities. The Group also offers integrated software solutions and automation tools to support digital transformation across research and quality control environments.

Bruker BioSpin’s customers in academic, government, industrial, and pharmaceutical sectors rely on these technologies to gain detailed insights into molecular structure, dynamics, and interactions. Our solutions play a key role in structural biology, drug discovery, disease research, metabolomics, and advanced materials analysis. Recent investments in lab automation, optical imaging, and contract research services further strengthen our ability to support evolving customer needs and enable scientific innovation.