Precisely controlling microbial growth is essential during bioprocess development, continuous manufacturing, and microbial physiology studies. Turbidostats enable stable and reproducible culture conditions by adjusting the inflow of fresh medium in response to real-time turbidity feedback, maintaining cultures at a consistent cell density.

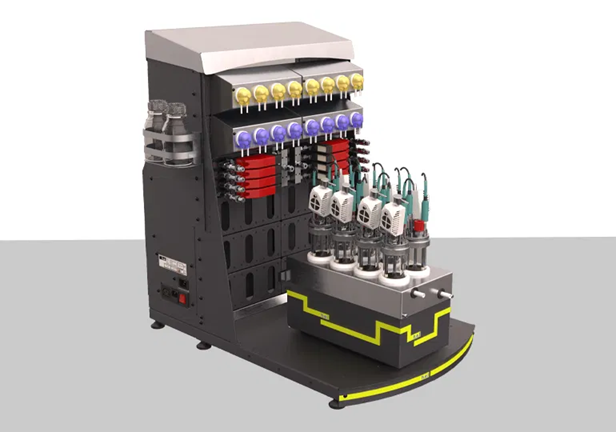

Figure 1. H.E.L BioXplorer 100, bench-top parallel 8 bioreactor platform. Image Credit: H.E.L Group

This article outlines how the BioXplorer 100 (Figure 1) can be operated as a turbidostat by using its integrated BioVIS probe (Figure 2) and WinISO software-controlled pumping system to maximize high-density Escherichia coli (E. coli) cultivation.

Optical scattering effects can cause non-linearity; to allow accurate correlation between cell density and probe output at high biomass, a non-linear calibration curve was developed.

Following calibration, the BioXplorer 100 successfully maintained a consistent E. coli cell concentration at the defined set point under continuous growth conditions. This supports consistent physiological states, high-productivity process development, and controlled experimental evolution.

Figure 2. BioVIS probe for online monitoring of total cell growth and biomass within a bioreactor. Image Credit: H.E.L Group

Key benefits

- Consistent high-density operation with self-operating dilution control

- Stable cell physiology for comparative or long-lasting experiments

- Parallel cultivation capability for optimization and screening workflows

- External optical monitoring equipment is not necessary

BioXplorer 100 operated as a turbidostat

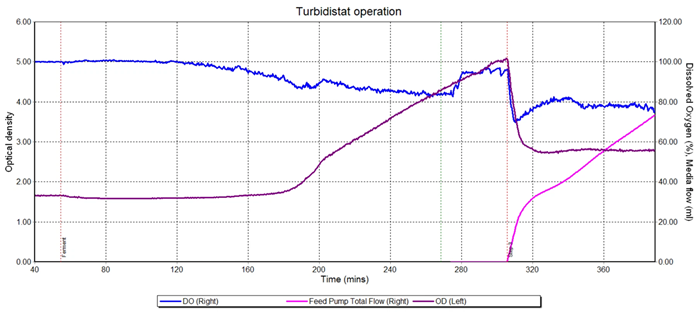

- Initial growth (∼0 to 155 minutes): The culture grows from time of inoculation (approximately 55 minutes). After a lag phase, OD increases and DO decreases as cells use up oxygen.

- Exponential phase (∼155 to 300 minutes): The biomass quickly increases, with continued DO decline reflecting high metabolic activity, until 275 minutes, at which point DO rises sharply, probably as a result of media exhaustion.

- Turbidostat control activated (∼300 minutes): After reaching the OD setpoint, the system automatically begins dilution.

- Feed pump flow increases as fresh medium is added.

- OD stabilizes at the defined target.

- Steady-state metabolic response: The addition of a fresh medium dilutes cell concentration to the set-point level, causing DO to increase before returning to a stable level.

Figure 3. Turbidostat control profile of BioXplorer 100. Image Credit: H.E.L Group

Conclusion

The BioXplorer 100 can be operated effectively as a turbidostat when supported by a non-linear turbidity calibration, delivering controlled, stable, and reproducible high-density cultivation.

Maintaining a consistent, high-density E. coli culture under consistent growth conditions allows the system to perform reproducible steady-state operation with limited human intervention.

The combination of real-time biomass monitoring, automated dilution control, and flexible parallel bioreactor configuration makes the BioXplorer 100 suited for applications including process optimization, adaptive evolution studies, strain development, and high-value biomolecule production.

Overall, the BioXplorer 100 provides a reliable and scalable platform for process developers and researchers who seek sturdy continuous cultivation capabilities. This performance enables reproducible continuous culture, supporting strain development, process optimization, and high-value biomolecule production with less manual intervention and higher confidence in experiments.

Introduction

Controlling microbial growth in liquid culture is crucial to industrial bioprocessing and biotechnology research. Traditional batch cultures exhibit dynamic shifts in metabolic state and nutrient availability, reducing their suitability when consistency and reproducibility are paramount. By automatically diluting the culture when turbidity exceeds a specific threshold, turbidostats provide continuous cultivation under steady growth conditions, preserving a consistent biomass. This allows:

- Steady-state metabolism and physiology

- Greater reproducibility between experiments

- Greater contribution to strain development research and microbial physiology

- Long cultivation times with no manual intervention

- Higher productivity levels for protein expression and biosynthesis

The BioXplorer 100 is a parallel, small-scale bioreactor system created for flexible bioprocess development. Its merged BioVIS probe gives continuous, in situ optical attenuation measurements that can be configured in WinISO to return calibrated OD-equivalent values in real time for automated growth regulation. However, accurately operating a turbidostat requires vigilant calibration between optical density (OD600) and probe signal, especially at high cell densities, where turbidity and OD no longer have linear correlation.

Materials and methods

Microbial culture growth conditions

- Organism: Escherichia coli

- Culture volume: 50 mL in BioXplorer 100 vessel*

- Temperature: 37 °C

- Agitation: 200 and 400 rpm

- Biomass Set Point: 2.75 g/L

- Control software: WinISO

Equipped with its BioVIS probe, the BioXplorer 100 was inoculated with E. coli culture and allowed to grow until reaching the necessary biomass setpoint. Once this point was reached, WinISO automatically started dilution control, introducing fresh medium and getting rid of liquid waste to preserve the consistent volumes and biomasses of cultures.

*A 50 to 150 mL culture volume can be used with the Bioxplorer 100, and a 120 to 400 mL culture volume with the BioXplorer 400.

The system consistently monitored turbidity and adjusted medium feed in real time, preserving the target cell density with no need for manual intervention. Extra culture volume was taken out automatically through a dip tube attached to an independent peristaltic pump for each vessel, controlled and preserved by the WinISO software.

Results and discussion

Calibration performance

Dilution is routinely performed when assembling offline samples for OD600 measurement by UV–Vis spectrophotometry, but it is not possible to perform when using an in situ optical probe. As a result, a non-linear calibration model was required to precisely relate the BioVIS attenuation signal to true cell density at high biomass. This calibration ensures that the BioVIS signal can be used reliably as the feedback input for continuous culture control.

Non-linear calibration of BioVIS probe

To create a calibration curve, samples were taken at progressive culture densities and measured offline at OD600 using a spectrophotometer. These OD values were related to the raw probe signal (transmitted light intensity).

The calibration curve below presents the relationship between the BioVIS probe output and the offline-measured OD600 of the E. coli culture. At low cell densities, the absorbance signal and OD600 are almost proportional, meaning the BioVIS output can be interpreted directly when OD600 is below ∼1.0.

At low OD600, the probe response was approximately linear. At higher densities (OD600 at 1.5), increasing light scattering caused non-linearity, thus necessitating a non-linear calibration model for precise biomass interpretation.

As cell density increases, the relationship becomes non-linear. Above ∼OD600 ≈ 1.5, the BioVIS signal increases less quickly than the true OD600. This is a result of dense cultures causing multiple scattering, reducing the amount of detected transmitted light, and breaking the proportionality assumed by the Beer-Lambert law in dilute solutions.

Applying the non-linear calibration model allows the BioXplorer 100 to precisely determine biomass across the full range of operation, enabling robust turbidostat control at high cell densities.

Summary

H.E.L’s BioXplorer 100 and BioXplorer 400 parallel bioreactor systems offer beneficial turbidostat capabilities, allowing the real-time control of culture density for a vast array of media and high-density microbial applications. When combined with the in situ BioVIS optical attenuation probe and WinISO-controlled automated dilution, these platforms maintain a steady biomass setpoint under continuous cultivation – ideal for long-running, steady-state processes.

With reliable long-duration operation, true parallel cultivation, and consistent cell physiology, the BioXplorer platform is exceptionally well-suited for strain optimization, screening studies, process development, and the production of high-value biomolecules.

Alongside the 100 and 400 systems, the BioXplorer 400P further extends the range by offering a reliable, scalable option for advanced pressurized bioprocessing applications. Together, the BioXplorer line provides comprehensive solutions for continuous microbial cultivation with flexible control strategies and integrated optical monitoring.

About H.E.L Group

H.E.L develops and manufactures innovative scientific instruments and software designed to optimize the efficiency, safety, and productivity of key processes in chemistry and biology applications.

The H.E.L team of 70 includes highly skilled process and software engineers, based at their extensive research and manufacturing facilities in the UK, as well as sales and support offices around the world.

H.E.L has a long history of solving complex challenges for customers. Since 1987, the Company has worked with businesses and laboratories globally, providing proprietary automated solutions for the pharma, biotechnology, chemical, battery and petrochemical sectors.

We continue to extend the reach of our products and services to support and enable R&D and process optimization further across Europe, the US, China, and India.

H.E.L is accredited with ISO 9001: 2015

Our mission

To help create a Healthier, Sustainable, Safer world for everyone.

Our vision

We equip scientists with the right tools and knowledge to develop safe, efficient new processes and molecules that benefit the world and its population.

Our values

- Insightful through experience. With over 30 years of in-house expertise and experience, we know how to overcome a challenge

- Collaborative by design. Dedicated to listening, learning, and working closely with industry experts, we empower others to fulfill potential

- Tenacious in spirit. Always looking for new and innovative solutions, we don’t stand still; instead, we are focused on reaching the next success

- Proud of progress. Fueled by our ability to make a real difference, while celebrating the achievements of others

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.net, which is to educate and inform site visitors interested in medical research, science, medical devices, and treatments.