If you’ve ever had to pause a promising experiment while waiting on titer results, you’re not alone. In many labs, samples come off the bioreactor only to sit in line for ELISA or HPLC - and decisions get delayed for days.

There is, however, a more efficient option. By combining the Ambr® 15 Cell Culture system with the Octet® Biolayer Interferometry (BLI) platform, teams can access same-day data, screen more conditions in parallel, and make faster, more confident decisions about what to move forward.

Cell culture setup for clone selection and media optimization. Image Credit: Sartorius Corporation

What changes with this combination?

Ambr® 15 brings true bioreactor control to early-stage development. With up to 48 single-use microbioreactors running in parallel at just 10–15 mL working volumes, scientists can efficiently screen clones, media, and process parameters - all under consistent, bioreactor-like conditions. The result is more informative data, lower material use, and greater confidence that successful conditions will translate at scale.

Octet® BLI complements this workflow with fast, label-free titer measurement. Instead of waiting on ELISA or HPLC queues, users can quantify protein directly from crude supernatants in standard microplates with minimal prep and hands-on time. This enables faster decisions, fewer handoffs, and a smoother path from sample to insight.

Ambr®15 Cell Culture

- Multiparallel microbioreactor cultures

- Clone screening and ranking

- Media screening

- Process optimization

Octet® Label-free Biomolecular Interaction Analysis

- Titer determination

- Evaluate critical quality attributes (CQAs)

- Stability and quality monitoring

Data Collection and Analysis Using MODDE® Software

- Assimilate data from platforms providing enhanced decision-making

- Allows teams to select better clones, screen more media, and optimize processes faster

Together, these platforms streamline the entire screening cycle. Teams can run multi-parallel cultures, sample at key time points, and quantify protein directly, turning tasks like clone ranking, media comparison, and process optimization into a same-day effort rather than a multi-week process. In practice, this approach reveals clear performance differences across media and conditions, highlighting the value of testing many variables in parallel.

A simple path off ELISA

For labs currently relying on ELISA, switching to an Octet® BLI assay doesn’t require starting from scratch. Most existing assays can be adapted with minimal re-optimization. A practical five-step approach supports a smooth transition, giving teams the confidence to make the move efficiently.

- Define what constitutes 'good' performance. Establish explicit objectives for range, sensitivity, precision, and throughput. This approach ensures that optimization remains targeted and prevents unnecessary complexity.

- Select the appropriate biosensor. Streptavidin serves as a flexible option for biotinylated ligands. Aminopropylsilane or amine-reactive chemistries facilitate covalent bonding. For quantifying antibodies, analyte-specific sensors such as Protein A or Protein G are typically the most straightforward choices. Make selections with regeneration and sample matrix considerations in mind.

- Determine the assay format. Direct binding is quick and uncomplicated for various quantification requirements. Sandwich formats enhance specificity and sensitivity in intricate matrices. Enzyme-linked methods offer signal amplification when extremely low detection limits are required.

- Reduce non-specific binding. Passivate the sensor surface, employ suitable blockers, and consider using mild detergents when beneficial. The objective is to achieve a clean baseline and stable signals without obscuring the analyte.

- Refine the buffer. Adjust pH, salt concentrations, blockers, and surfactants to optimize the signal-to-noise ratio and ensure the well-being of the analyte, particularly when dealing with crude samples.

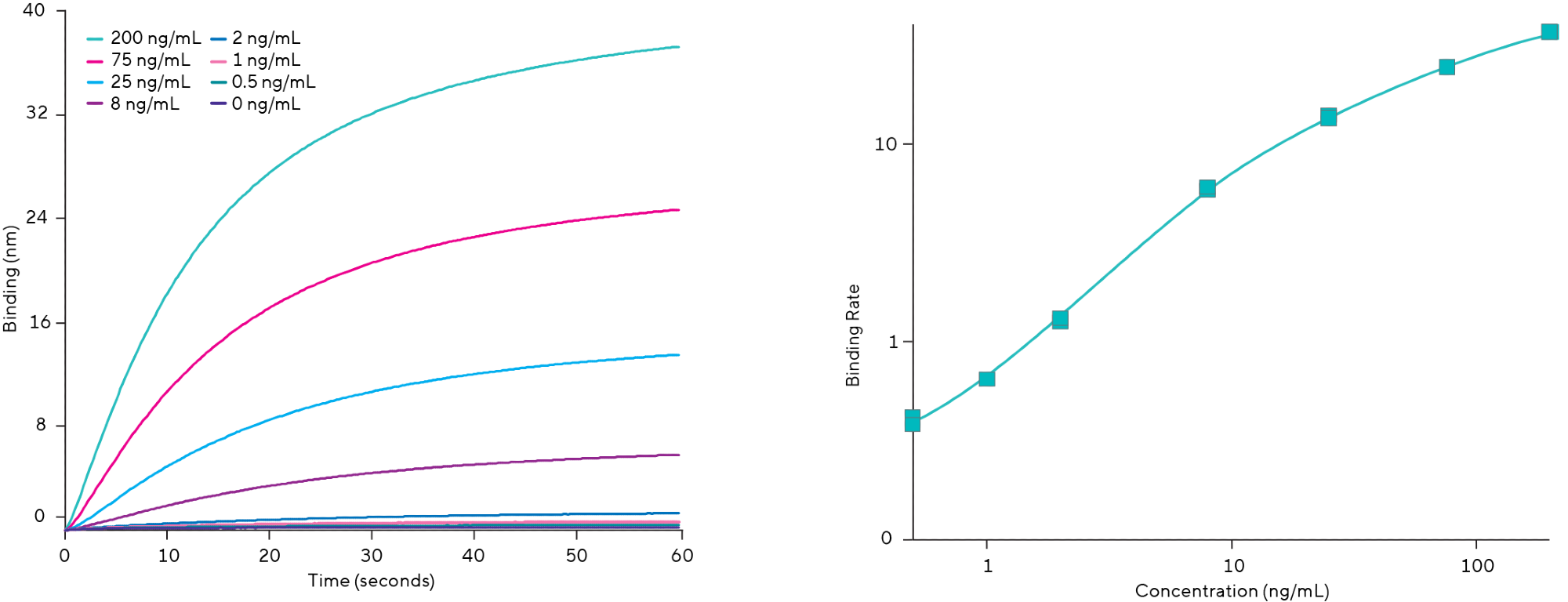

Raw data example and the resulting standard curve (n = 3) with a limit of detection of 0.5 ng/mL. Image Credit: Sartorius Corporation

Why it matters

This pairing delivers earlier, more informative signals without overloading specialized analytical teams. Quantitation stays within the development lab, helping reduce costs and avoid delays from external testing queues. By combining this with the full parallel capabilities of Ambr®, teams can explore more conditions at once. The result is faster, more confident decision-making, with promising candidates advancing sooner and non-viable options eliminated before they consume time and resources.

Who benefits?

- Cell line development teams seeking to enhance screening capabilities without increasing personnel

- Process development teams in search of preliminary indicators that can be scaled up

- Organizations focused on reducing timelines and minimizing the effort required for each sample assay

Getting started

Ambr® experiments should be planned with a specific intention in mind, such as ranking clones across multiple media or comparing a set of process parameters. Then, the Octet® BLI can be used for same-day titer readings directly from crude supernatants.

Implement the five-step conversion method to modify the existing ELISA, standardize workflow, and incorporate swift and consistent decision-making into regular practice.