3D bioprinting is an emerging technology with applications throughout the complete range of biomedical research.

The method directly builds on 3D printing technologies employing a biological substrate or ‘bioink’, made of structural components, growth media, and cells, to produce 3D biological structures that closely imitate the structure of cells in living organisms.

Using the same additive manufacturing model as traditional 3D printing, a number of 2D slices are divided from a 3D model by a computer to print an accurate biological composition layer-by-layer with a precise arrangement of tissues and cells.

3D bioprinting offers an opportunity to solve issues in drug development, regenerative medicine, organ donation, and cancer treatment.

As with all emerging technologies, researchers are also creating solutions to its challenges to enhance the prospects of this innovative tool.

Applications of 3D Bioprinting

Cancer Treatment

Researchers are already showing the future possibilities of 3D bioprinting technology for the biomedical field. Cancer research is one area in which scientists are hoping 3D bioprinting will prove to be beneficial.

The tumor microenvironment, the biological structures and substances surrounding the tumor and not just the cells, is an essential area of cancer behavior that is not yet fully understood.

Animal models and 2D cell cultures have been employed with some effectiveness, but they do not precisely show the behavior of human cancer cells in vivo, which comprises a complicated interaction between tumor cells with both the cellular environment in 3D space and other cells.

Research suggests that 3D models more accurately reflect tumor cell behavior and bioprinting is a promising approach that is being investigated.

One advantage that 3D bioprinting offers compared to alternative approaches is that cells can be directly configured into a 3D model with their extracellular and structural elements.

Image Credit: SunP Biotech

Alternative approaches differ in that they demand self-assembly, which is a much more time-intensive process, or scaffolding, where the support matrix is built independently from the cell culture.

Not only does 3D bioprinting provide the opportunity to print particular tissue and cell structures, but the method can also be specific to patients.

The cells of a patient can be biopsied, grown, and bioprinted into appropriate structures to investigate drug response or to customize the dosage of a drug to enhance its efficacy.

Drug Development

Another key discipline where 3D bioprinting is predicted to thrive is in the drug development field.

The majority of drug testing is currently performed employing 2D cell cultures. Similar to cancer research, these cultures do not support natural cell behavior.

Xenografting (human cell transplantation) to animals is now utilized to help solve this issue, but it has challenges as a result of the biochemical, metabolic, and genetic variations between the species.

It has been suggested that these issues could be contributing factors to the high rate of failure in new drug candidates. The majority of these, all but 1 in 5000, will fail to make it to market at a huge expense to the pharmaceutical industry.

Critically, the use of 3D bioprinted cell structures for pharmaceutical testing rather than in vivo studies does not need regulatory approval, possibly multiplying the throughput of drug development.1

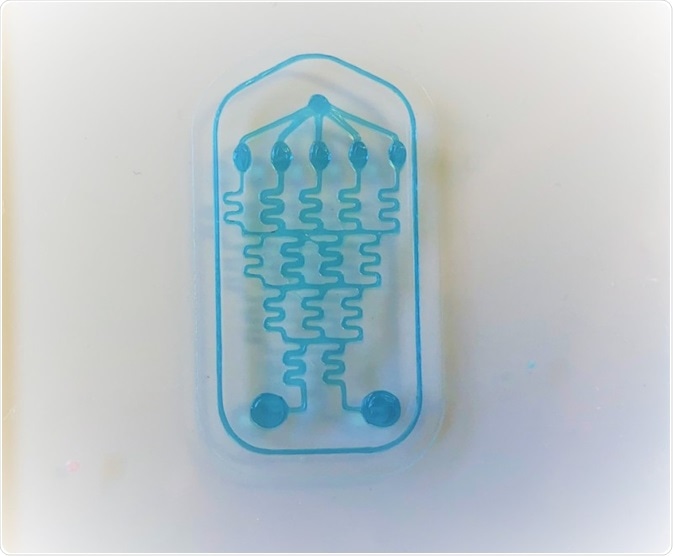

Organ-On-A-Chip Models

Printing 3D structures utilizing several cell types allows researchers to quantitatively investigate complicated biological systems, even those that are not found in nature.

Image Credit: SunP Biotech

3D bioprinting allows for the production and design of miniaturized ‘organ-on-a-chip’ models, which can be employed for quantitative investigations of cell function, metabolism, protein secretion, and gene expression; along with pre-clinical pharmaceutical testing and drug-delivery systems.2,3

Regenerative Medicine

Regenerative medicine may be one of the most exciting applications of 3D bioprinting.

Researchers hope that bioprinting can be employed to directly print tissues such as skin into living patients, and to create organs, tissues, and structures for transplantation.

3D bioprinting is effectively employed for the transplantation and production of multilayered bone, skin, tracheal splints, vascular grafts, cartilaginous structures and heart tissue.4

Researchers anticipate that tissues and eventually complete organs could be transplanted to patients produced from their cells in the future. With the assistance of 3D bioprinting, transplant rejection and time-consuming donor lists could become an issue of the past.

Refining Technology

As a newly-emerging technology, 3D bioprinting still has a host of challenges to solve before its complete potential can be unleashed.

An essential challenge is the requirement to reduce the cell damage throughout the printing process while still keeping the structural integrity of the 3D arrangement intact.

These two aims are conflicting as the hydrogels normally utilized in bioinks that guard the cells against shearing forces throughout the process of printing are structurally weak.

A large number of scientists working in this field are producing technology to perform their research, which automatically reduces the time available for biological enquiry.

For biologists who do not specialize in this field, the requirement to familiarize themselves with new technology could create a challenge when discovering this promising and emerging area.

Delivering Advancements

In response to the demand for user-friendly, fully versatile, and robust 3D bioprinting technology in biomedical research and development, SunP Biotech has produced ranges of bioinks and bioprinters that make 3D bioprinting affordable, accurate, and accessible.

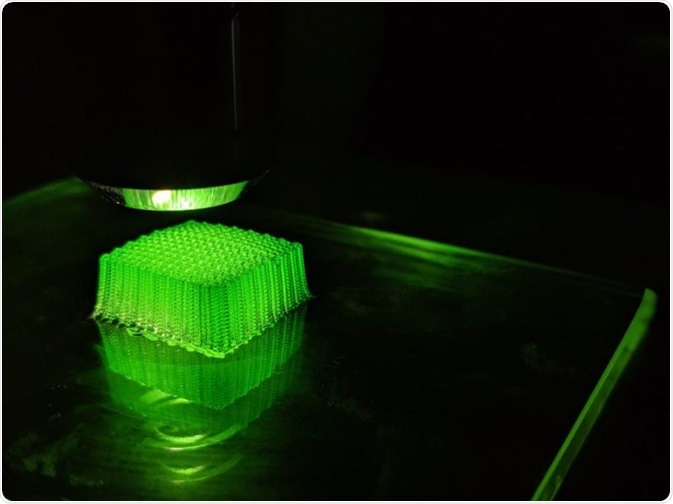

3D Bioprinting of different Bioinks using Biomaker

Image Credit: SunP Biotech

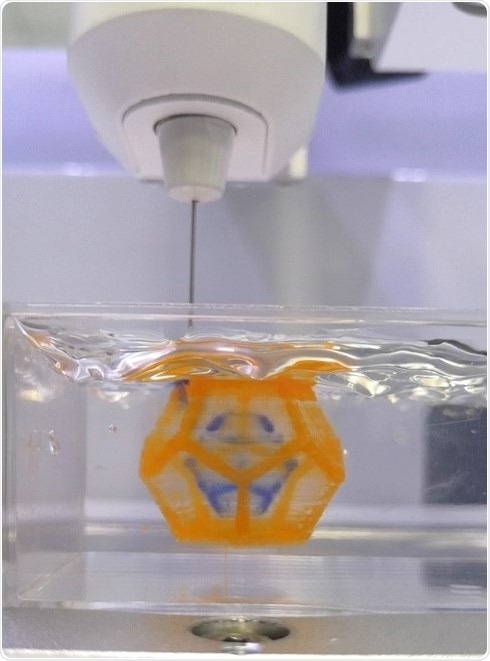

The BIOMAKER is the latest in a range of 3D bioprinters and blends intuitive software and high-performance hardware in a compact desktop unit.

Image Credit: SunP Biotech

The BIOMAKER provides unprecedented versatility with a range of modular nozzle systems, enabling operators to print with cells and alternative media with essentially unlimited biophysical features. Every nozzle has specialized characteristics to enable printing for general and adaptive biomaterials.

Image Credit: SunP Biotech

Not only does this assist in guarding the cells along with upholding structural integrity, it also provides the printing of layered tissues that are seen in nature, for example, the skin.

The temperature of the nozzles and build plates can be adjusted from 10 °C to 40 °C. This allows for the adjustment of the bioinks' viscosity and ensures the viability of cells throughout printing.

Image Credit: SunP Biotech

UV sterilization and an integrated HEPA filter are additional features of the compact printer, which promote a sterile work environment, with no requirement for a bio-safety cabinet. It even has a footprint that is small enough to fit on the workbench.

Founded by biomedical experts, SunP Biotech has the express intention of removing the need for researchers to produce bioprinting equipment.

The versatility of their research-grade bioprinters and bioinks, for example, the BIOMAKER, are helping biomedical researchers around the globe to spend less time on sourcing and creating equipment and more time focusing on their expertise.

References and Further Reading

- Ozbolat, I. T., Peng, W. & Ozbolat, V. Application areas of 3D bioprinting. Drug Discovery Today (2016). doi:10.1016/j.drudis.2016.04.006

- Bhise, N. S. et al. Organ-on-a-chip platforms for studying drug delivery systems. Journal of Controlled Release (2014). doi:10.1016/j.jconrel.2014.05.004

- Park, J. Y., Jang, J. & Kang, H. W. 3D Bioprinting and its application to organ-on-a-chip. Microelectron. Eng. (2018). doi:10.1016/j.mee.2018.08.004

- Murphy, S. V & Atala, A. 3D bioprinting of tissues and organs. Nat. Biotechnol. 32, 773–785 (2014).

- AZoMaterials. 3D bioprinting and its applications (2018). https://www.azom.com/article.aspx?ArticleID=17370

- Harris M (2018) Print me an organ. https://physicsworld.com/a/print-me-an-organ/

- Organovo (2015) 3D Cell Culture: Technologies and Global Market, Robert Hunter, ISBN: 1-62296 -006-8, Pharmaceutical Research and Manufacturer of America.

- Wang C, et al. Three-dimensional in vitro cancer models: a short review. Biofabrication 2014; doi: 10.1088/1758-5082/6/2/022001.

- Yao R, et al. Three-dimensional printing: review of application in medicine and hepatic surgery. Cancer Biol Med 2016; doi: 10.20892/j.issn.2095-3941.2016.0075.

About SunP Biotech

We are a team of pioneers focused on developing solutions in the biotechnology industry. While developing state-of-the-art research in the biomedical industry, the experts at SunP Biotech realized that the amount time and effort spent developing a 3D Bioprinter could be focused on developing new medicine and biomedical devices. The group took this vision and started SunP Biotech in 2014 with the intent to develop and manufacture standardized, compact, and simple 3D biofabrication products. The team designed and created an advanced bioprinting system that uses a patented screw-based extrusion technique that eliminates the need for additional heavy equipment that sometimes accompanies pneumatic systems.

SunP Biotech creates advanced products that push for the highest quality of precision, accuracy, and sterility, so our users can perform research safely and confidently. Our passion and expertise in the industry allows us to create custom products that fit the needs of our clients. Our products have been adopted in areas of tissue engineering, biomimetic design, pharmaceutical research, organ-on-a-chip, and drug testing. SunP’s mission is to streamline companies’ approach into 3D bioprinting with a modern and simple bioprinter that that will help them focus on their objective and accelerate their research.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.