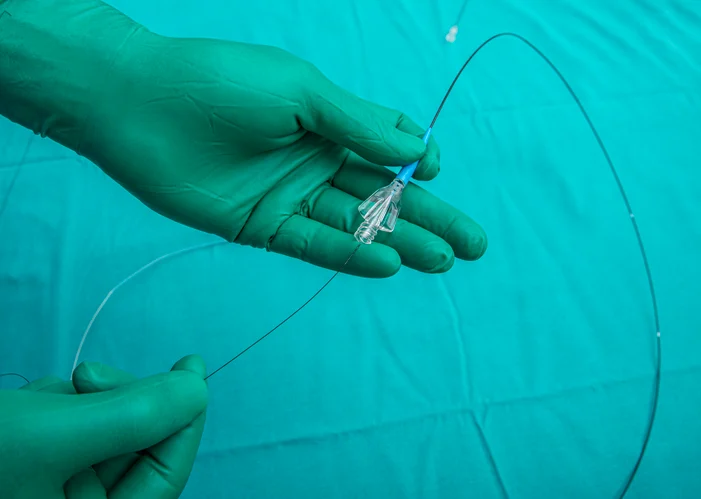

Catheters play an essential role in modern medicine, serving as vital tools for diagnosing and treating various medical conditions. In the pursuit of more precise and accurate measurements of physiological parameters, the integration of sensors into catheters has become increasingly common.

Image Credit: Amphenol Sensors

Incorporating sensor technology into catheters is not a simple plug-and-play process. Rather, it requires careful planning and consideration of several key variables that can significantly impact performance and accuracy. Thus, catheter design and material considerations become crucial when it comes to integrating sensors.

Design consideration for sensors in catheters

Certain fundamental principles apply when designing catheters with integrated sensors, regardless of the catheter type, whether that be Foley catheters or intracranial catheters. The following design considerations should always be taken into account:

- Torque: The catheter should be able to withstand the torque generated during guide wire insertion, navigating through arteries, and twisting of the catheter tubing.

- Adhesion: The catheter material should resist adhesion to tissue to prevent discomfort or damage.

- Flexibility: The catheter tube should possess sufficient flexibility to allow for movement without compromising its overall integrity.

- Strength: The chosen catheter material should be strong enough to endure repeated insertions and removals from the body without experiencing deformation or damage.

- Infection prevention: The catheter should be designed with infection prevention in mind, utilizing materials that resist bacteria and other microorganisms.

- Kink resistance: The catheter should withstand sharp bends without sustaining permanent damage.

However, when incorporating sensors into the catheter design, additional factors come into play. During the design process, every catheter manufacturer should consider the following:

- Size

- Real estate

- Environment

- Housing

- Lead length

- Supply voltage

- Calibration accessibility

1. Size

One of the fundamental aspects to consider is the size of the catheter.

The sensor technology employed in catheters should be able to fit safely and comfortably within the devices, allowing them to maintain their integrity and effectiveness. Additionally, the size of sensor components must be compatible with other parts of the device, such as tubing, connectors, valves, and so on, ensuring proper functionality.

2. Real estate

While sensor size is important, having sufficient space inside the catheter to incorporate the sensor into its design without compromising other features and functionality is equally crucial.

Space is at a premium in catheters, especially in miniature devices, and managing the available real estate for sensors and other components is a critical aspect throughout the design and manufacturing process. This is particularly true for miniature devices.

3. Environment

When catheters are inserted into the body, they encounter various environmental factors, such as pressure, temperature, and chemicals, which directly influence the performance of the device and its components. For sensors, this entails ensuring that their materials and design can withstand these external conditions, which can sometimes be extreme.

It is also important to consider how the sensor interacts with other components in the device, as temperature changes caused by environmental pressures can affect the effectiveness of neighboring components.

4. Lead length

The lead length refers to the distance from the device body or connector to the point where it interfaces with the signal conditioning circuit board. The lead length needs to be long enough to capture the signal effectively but short enough to avoid interfering with the movement of other components or parts of the device.

It is essential to strike a balance, as longer lead lengths can introduce electrical noise, signal attenuation, and a degraded signal-to-noise ratio, while shorter lead lengths can offer better signal quality but increase the risk of mechanical damage.

5. Sensor housing

Sensor housing is a critical consideration, particularly for pressure sensors. The housing serves to protect the monitoring device, providing durability and reliability against environmental factors and vibrations.

Inside a catheter, a pressure sensor's housing serves an additional role, acting as a shield against electromagnetic interference (EMI) signals that may pass through the device.

EMI signals can cause inaccurate readings, incorrect measurements, reduce the accuracy of the output, and even lead to sensor malfunctioning. Moreover, they can disrupt communication between other components in the device.

6. Supply voltage

Maintaining a consistent supply voltage is crucial for monitoring devices, especially for pressure sensors. Pressure sensors convert pressure signals into electrical signals, which are then processed to obtain pressure measurements.

The accuracy of this conversion process is heavily reliant on a stable and consistent supply voltage. Fluctuations in the supply voltage can introduce errors in pressure readings obtained from the sensor.

Sudden spikes or decreases in a pressure sensor's supply voltage directly impact the accuracy and reliability of its readings.

7. Calibration accessibility

Whether it is a MEMS pressure sensor or a medical temperature sensor, catheter sensors are typically uncalibrated. The catheter's manufacturer is responsible for fine-tuning and testing the sensor to ensure proper functionality.

To accomplish this, direct access to the sensor is necessary, which requires the catheter to have a channel or opening that allows users to easily adjust, test, and calibrate it.

Depending on the sensor type, different openings may be required. Once calibration is complete, it is crucial to seal the access points properly to prevent unintentional breaches that could render the device useless.

Material considerations for catheters and their components

Biocompatibility is a key consideration that applies to all material types used in catheters.

It refers to the property of materials being compatible with insertion into the body. This is particularly important for catheter manufacturing, as the device and its components need to function within the body without causing harm or irritation to the patient.

The materials used for catheter components must be resistant to environmental factors such as temperature and pressure while ensuring accurate readings for the sensors.

Manufacturers need to consider not only the compatibility of materials but also how they interact with each other, especially when components are sourced from different suppliers. Thorough testing of individual components and their collective compatibility is essential to determine the optimal material choices for the catheter design and use case.

Catheter design for optimized sensor performance

It is crucial to have well-designed and properly manufactured components to ensure the expected performance of catheters used for patient treatment.

Successful integration of body sensors into catheter designs requires careful consideration at every stage, from development to production. By attentively addressing all these factors, catheters can be designed to deliver optimal performance with consistently reliable readings.

About Amphenol Sensors

Amphenol Sensors, with its portfolio of industry-leading brands - Thermometrics, NovaSensor, Telaire, Protimeter and Kaye - is an innovator in advanced sensing technologies and innovative embedded measurement solutions customized for regulatory and industry driven applications, creating value by providing critical information for real-time decisions.

We offer domain expertise, rapid customization, world-class manufacturing capability and lasting customer relationships deliver the greatest value in cost of ownership to their customers.

Amphenol Sensors is a member of the USA-based Amphenol Corporation. With our own global presence we offer our customers exceptional technical support and service in the areas of development, production and distribution.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.