Sponsored Content by SCIEXReviewed by Louis CastelSep 25 2025

This article shows a >2x improvement in robustness when analyzing PFAS food extracts on the SCIEX 7500+ system. At the conclusion of the trial, which included approximately 6400 food matrix injections, the majority of PFAS compounds (10 out of 13) retained >70% of their initial sensitivity.

The presence of interfering co-extractables in food matrices complicates residue analysis, potentially resulting in instrument contamination and system downtime.

The robustness of the SCIEX 7500+ and SCIEX 7500 systems was assessed in an accelerated manner using an aggressive sample preparation technique and missing the diverter valve.

The SCIEX 7500+ system includes innovative Mass Guard technology, which improves instrument robustness while retaining optimal sensitivity for longer.1

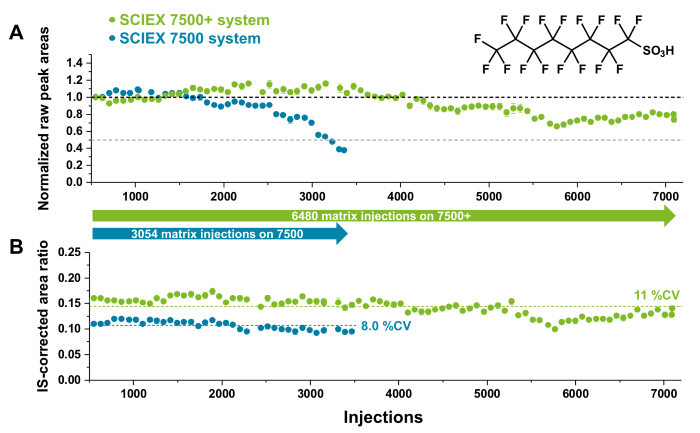

Figure 1. Raw peak areas normalized to initial response (A) and internal standard (IS)-corrected peak area ratios (B) for perfluorooctane sulfonate (PFOS) in solvent quality control (QC) samples on the SCIEX 7500 (blue) and on the SCIEX 7500+ (green) systems. Each datapoint represents the mean with standard error bars. In panel A, the dotted lines represent the 100 % and 50 % raw peak areas relative to the initial response. Robustness was compared based on the total number of injections before the instrument sensitivity declined to 50 % of the maxima. In panel B, the dotted lines represent the overall mean and %CV for each experiment. Food extracts were injected between each solvent QC datapoint. Image Credit: SCIEX

Key benefits of high-throughput PFAS analysis in food using the SCIEX 7500+ system

- Enhanced robustness from Mass Guard technology: The SCIEX 7500+ system has improved hardware components to reduce contamination and maintain instrument uptime.

- Exceptional instrument stability: The SCIEX 7500+ system achieved >2x improvement in robustness, with over 6,400 injections of food matrices compared to over 3000 injections on the SCIEX 7500 system.

- User-accessibility via an extractable DJet+ assembly: Increased flexibility for user cleanup as needed.

Introduction

The complexity of the matrix makes high-throughput analysis of PFAS in food samples challenging. Instrument robustness is critical for ensuring good test performance with minimal downtime.

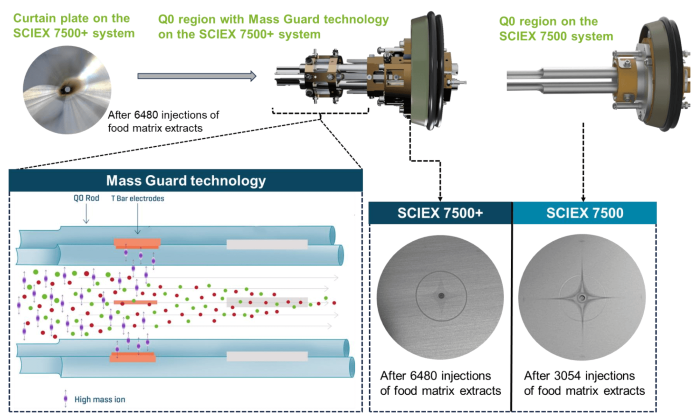

The SCIEX 7500+ system retains the high sensitivity of the SCIEX 7500 system while also providing increased resilience via Mass Guard technology.1 This involves the addition of T Bar electrodes to the Q0 region, which actively filters out contaminated ions and produces a cleaner ion beam (Figure 2).

Visual analysis of the downstream ion optics demonstrates that the SCIEX 7500+ system has fewer pollution deposits than the SCIEX 7500 system on the IQ1 lens. Furthermore, the SCIEX 7500+ system improves customer access to the instrument's front-end DJet+ assembly, allowing for easier cleaning.1

The long-term robustness of the SCIEX 7500+ and SCIEX 7500 systems was tested under accelerated settings.

Figure 2. Hardware components of Mass Guard technology. The added T Bar electrodes in the Q0 region of the SCIEX 7500+ system actively remove contaminating ions (purple symbols), resulting in a much cleaner sample plume (red and green symbols) entering the instrument. Visual comparison of the ion optics downstream of the T Bar electrodes showed less impact from matrix contamination despite significant residue deposited on the source curtain plate (top left), when compared against the same component on the SCIEX 7500 system without this protection, as shown on the bottom right. Image Credit: SCIEX

Methods

To assess the robustness of both systems, the experimental regime was constructed to maximize the matrix load injected over successive weeks, which included:

- A diverse range of food matrices

- More matrix interferences were found in the extracts due to a modified sample preparation method compared to standard optimized methods.

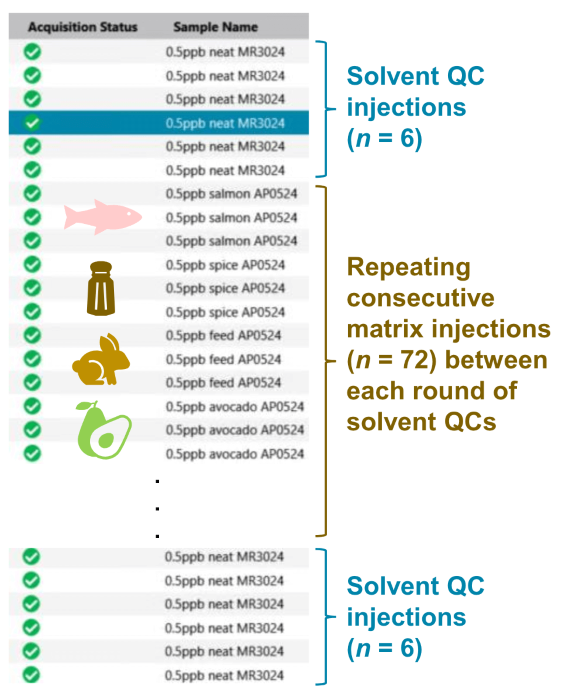

- Short duration allows for more consecutive matrix injections between solvent QCs (Figure 3).

- Acquire continuously without using a diverter valve or doing any maintenance on the mass spectrometer.

Samples and reagents: Wellington Laboratories provided native and mass-labeled PFAS standards for preparing quality control (QC) samples in solvents and matrix post-spikes in food extracts. Salmon fillets, avocado, five-spice powder, and rabbit feed were bought from local supermarkets.

Figure 3. Injection sequence on both systems. Robustness was evaluated by consecutive injections of food matrix extracts that were bracketed by solvent QC replicates at a frequency ratio of 12:1 matrix:solvent, i.e. 72 matrix injections for every 6 solvent QC replicates. Image Credit: SCIEX

Sample preparation: To prepare the samples for extraction, a food processor was used to homogenize the salmon fillet and avocado (~50 g each), and a mortar and pestle was used to grind the rabbit feed (50 g).

The food samples were extracted using a QuEChERS method designed for PFAS measurement in food, but the final solid-phase extraction (SPE) step was skipped to maximize impurities in the final matrix extracts.2

In a 50 mL centrifuge tube, 5 g of homogenized salmon or avocado (or 2 g of feed or spice powder) was mixed with water. This was 5 mL for salmon/avocado or 15 mL for feed/spice powder. This was then followed by extraction with 12 mL of acetonitrile and 150 µL of formic acid.

After adding a QuEChERS packet (6000 mg MgSO4, 1.5 g NaCl; Phenomenex P/N AH0-9044), the sample was vortexed and agitated for 5 minutes at 1500 rpm.

After 5 minutes of centrifugation at 10000 rcf, the supernatant was transferred to a 15 mL dispersive (dSPE) tube (900 mg MgSO4, 150 mg PSA, 45 mg GCB; Phenomenex P/N KS0-9510). After shaking and centrifuging the dSPE tube, the supernatant was evaporated until dry and reconstituted in 10 mL of methanol.

This final methanolic extract was divided into equal 1 mL aliquots with a solvent ratio of 80:20 (v/v) methanol/water.

Solvent QC samples were created by spiking a mixture of native and mass-labeled PFAS standards with the same solvent composition as the food matrix extracts. As shown in Figure 3, the instrument's resilience was assessed by monitoring the solvent QCs between large blocks of successive matrix injections.

Chromatography: The ExionLC AC system was used for chromatographic separation, using a Luna Omega PS C18 analytical column (100 x 3.0 mm, 3 µm, Phenomenex P/N 00D4758-Y0) and a delay column (50 x 3.0 mm, 5 µm, Phenomenex P/N 00B-4753-Y0).

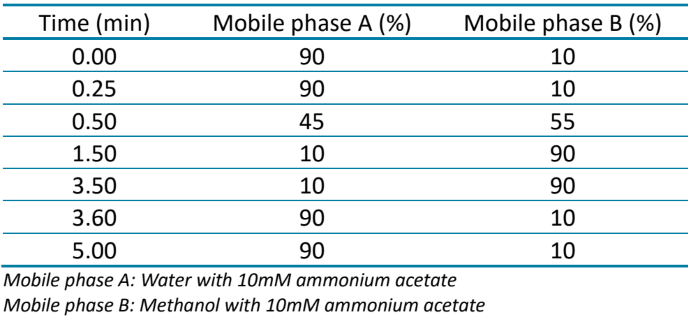

The SecurityGuard ULTRA UPLC Fully Porous PS C18 cartridge (Phenomenex part number AJ0-9508) was utilized. A flow rate of 0.8 mL/min, injection volume of 10 µL, and column temperature of 40 °C were utilized. Table 1 shows the LC gradient used.

Table 1. LC gradient. Source: SCIEX

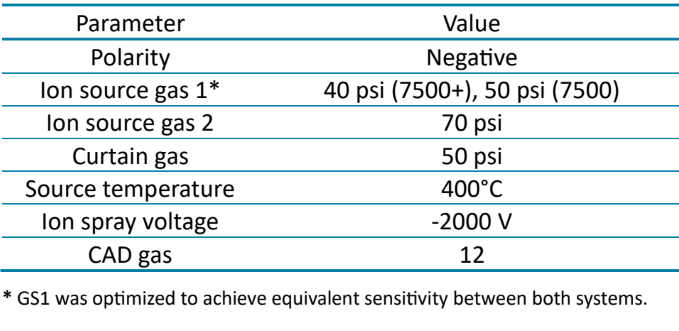

Mass spectrometry: Analysis was carried out utilizing scheduled multiple reaction monitoring (sMRM). Table 2 displays the source and gas characteristics used in both systems. MRM settings were optimized for the target PFAS.

Table 2. Source and gas parameters. Source: SCIEX

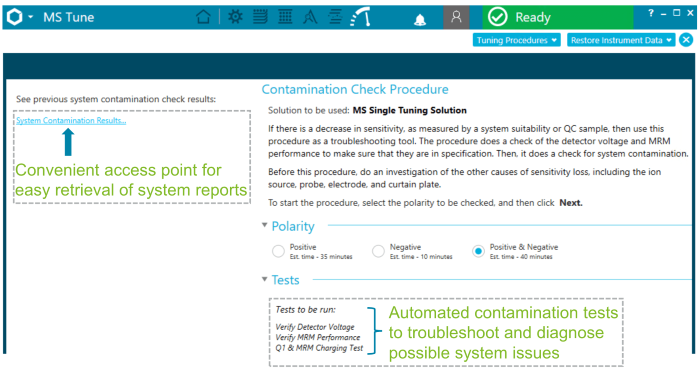

Data processing: Data collection and processing were carried out using SCIEX OS software, version 3.4.0. The SCIEX OS software included built-in automatic checks to monitor instrument contamination for quick and easy troubleshooting.

Comparison of robustness performance between the SCIEX 7500+ system and SCIEX 7500 system

The foods selected for matrix injections (salmon, spice powder, avocado, and rabbit feed) reflect the variety of food samples evaluated by normal testing facilities. Rabbit feed was used as a surrogate for silage, which is known to contain significant amounts of interference.

After more than 3000 injections on the SCIEX 7500 system, preliminary trials employing the entire US FDA extraction and clean-up procedure2 revealed no significant sensitivity decline for any target analyte.

The final SPE clean-up was eliminated to enhance the matrix interference burden on the system. However, these alterations represent demanding conditions, and the optimal extraction and clean-up process should be used for routine food analysis.

Figure 1A demonstrates the robustness performance using the uncorrected raw peak areas observed. Following the initial 500 matrix injections, solvent quality control monitoring commenced. The raw peak regions were normalized to the initial stabilized response, as indicated by the 100% black dotted line in Figure 1A.

To compare robustness, the total number of injections required until the instrument's sensitivity dropped to 50 % of its initial response was used. Both devices displayed excellent robustness, as shown by Figure 1A for perfluorooctane sulfonate (PFOS).

On the SCIEX 7500 system, the raw peak areas of PFOS remained steady for ~2500 injections before decreasing to 50 % after >3000 injections. More remarkably, the SCIEX 7500+ system outperformed this injection count by more than two times, with PFOS sensitivity remaining consistent at 80 % after more than 7000 injections.

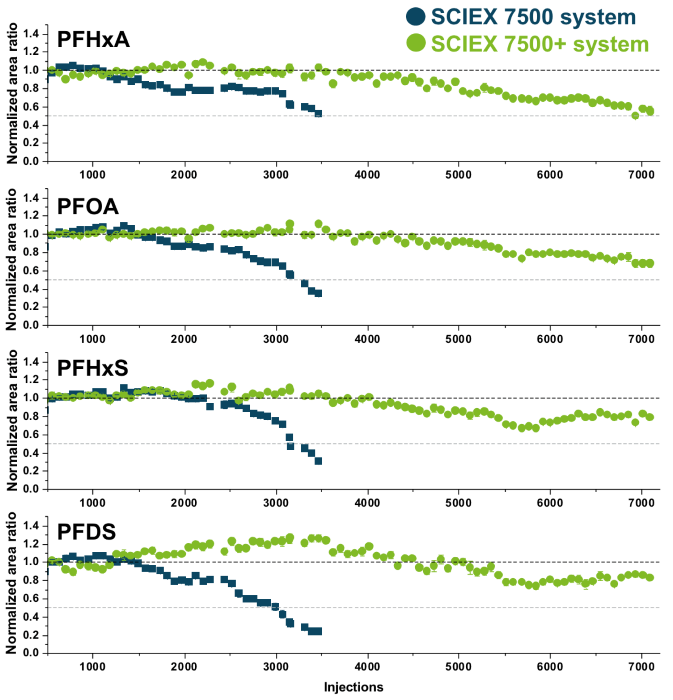

Similar robustness trends were found for the other target PFAS (Figure 4). At about 3400 injections, 11 of the 13 PFAS examined preserved more than 90 % of their initial sensitivity on the SCIEX 7500+ system, while the majority of the analytes had decreased to less than 50 % on the SCIEX 7500 system.

This sensitivity performance remained good on the SCIEX 7500+ system after 7000 injections, with most analytes still responding at 70% of their initial value.

Figure 4 shows a visual comparison of the SCIEX 7500+ system's better resilience to the SCIEX 7500 system for four different representative PFAS: PFHxA, PFOA, PFHxS, and PFDS.

Isotope-labeled internal standards (IS) are widely employed in PFAS food analysis. However, because the native and internal standards respond similarly to the assay environment, IS-corrected peak regions can disguise an instrument's true performance.

For example, the percentage CVs of the IS-corrected area ratios of PFOS were 8 % for more than 3300 injections on the SCIEX 7500 system and 11 % for more than 7000 injections on the SCIEX 7500+ system (Figure 1B).

This consistency indicates that the instrument's performance remained steady throughout the experiment, despite the severe conditions, such as the high matrix load fed continually to the ion source without the protection of a diverter valve or any interim maintenance.

As a result, uncorrected raw peak areas provide a more accurate indication of instrument performance over time and can alert the user when maintenance is required.

Figure 4. Comparison of robustness trends observed for perfluorohexanoic acid (PFHxA), perfluorooctanoic acid (PFOA), perfluorohexane sulfonate (PFHxS) and perfluorodecane sulfonate (PFDS) in solvent QC samples injected on the SCIEX 7500 system (blue) and SCIEX 7500+ system (green) throughout the experiment. Each datapoint represents the average of replicate injections with its associated standard error bars. The black and grey dotted lines represent the initial stable analyte response at 100 % and 50 % of that initial response, respectively. Image Credit: SCIEX

Enhanced software tools for system performance tracking

System suitability tests (SSTs) using QC samples are essential for guaranteeing data correctness and repeatability in long-term experiments. Intermittent infusion-based checks can also offer real-time information about the instrument's functioning across acquisition batches.

SCIEX OS software includes an automatic procedure that allows the user to monitor detector performance and system charging without manual intervention (Figure 5).

Any suboptimal performance determined by the SSTs and contamination tests would necessitate instrument maintenance. The replaceable DJet+ assembly on the SCIEX 7500+ system enhances front-end serviceability by giving the user greater control over maintenance scheduling and system uptime.

Figure 5. Built-in contamination check procedures in SCIEX OS software for easy troubleshooting. The MS Tune module in SCIEX OS software provides an automated contamination check procedure that allows the user to troubleshoot and monitor instrument performance during sensitivity loss. At the end of the procedure, the software generates a summary report of the instrument health based on the tests ran. Image Credit: SCIEX

Conclusion

Mass Guard technology actively removed contaminating ions in complicated matrices, conferring outstanding robustness to the SCIEX 7500+ system.

The SCIEX 7500+ system maintained quantitative performance after over 7000 injections of food extracts and solvent QC samples, with most PFAS analytes retaining more than 70 % of the initial peak area sensitivity.

SCIEX OS software enhancements for system performance tracking and the extractable DJet+ assembly provide enhanced flexibility for user-initiated system maintenance and uptime management.

Building on the renowned sensitivity of the SCIEX 7500 system, the SCIEX 7500+ system delivers exceptional data stability to provide a robust and high-performance platform for PFAS analysis in food.

References and further reading

- Build resilience with the 7500+ system. SCIEX brochure, MKT-31468-A.

- Genualdi, S., et al. (2023). Analyte and matrix method extension of per- and polyfluoroalkyl substances in food and feed. Analytical and Bioanalytical Chemistry, 416(3), pp.627–633. https://doi.org/10.1007/s00216-023-04833-1.

Acknowledgments

This article was produced using materials originally authored by Holly Lee1, Ian Moore1, Craig M. Butt2, and Elliott Jones.2

1 SCIEX, Canada

2 SCIEX, USA

About SCIEX

The mission of SCIEX is to deliver solutions for the precision detection and quantitation of molecules, empowering our customers to protect and advance the wellness and safety of all.

SCIEX has led the field of mass spectrometry for 50 years. From the moment we launched the first ever commercially successful triple quad in 1981, we have developed groundbreaking technologies and solutions that ensure global food safety today.

Today, as part of the Danaher family of global life science and technology innovators, we continue to pioneer robust solutions in mass spectrometry and capillary electrophoresis. But we don’t just develop products. It is what we do together with our customers that sets them apart. That’s why thousands of food experts around the world choose SCIEX to get the answers they can trust and keep running - day in and day out with consistent performance.

We proudly stand behind our tagline: The Power of Precision.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.