3D bioprinting involves the precise deposition of biocompatible materials, cells, growth factors, and essential support materials to create functional, intricate living tissues. This technology has been applied successfully to fabricate various tissue types, including skin, bone, vascular grafts, and cartilage structures.

Figure 1. Printed Fibers using a G30 needle; scale bar represents 500 μm. Image Credit: Merck

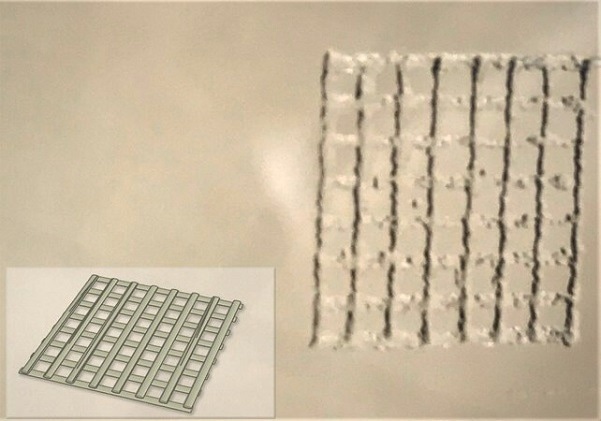

Figure 2. 3D printed grid-like structure using TissueFab® GelMa UV; CAD design (inset). Image Credit: Merck

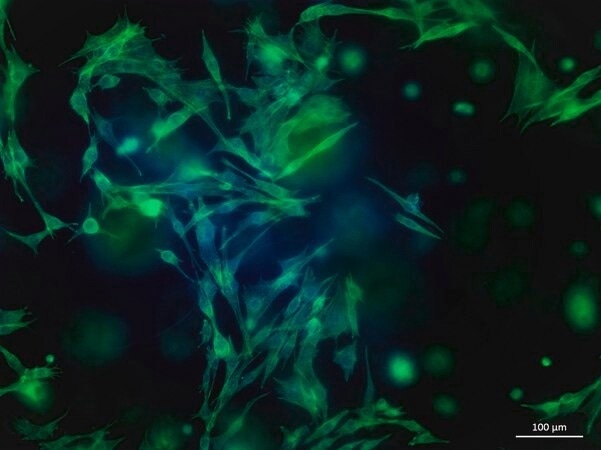

Figure 3. Morphology of C2C12 after 7 days post-printing with TissueFab® GelMa UV. Cell cytoskeleton stained with F actin (green) and nuclei DAPI (blue). Image Credit: Merck

The choice of materials and formulations is tailored to achieve specific tissue properties, encompassing both rigid and flexible tissues. While several 3D printing methods are available, extrusion-based techniques using bioinks are commonly preferred due to the delicate nature of the materials involved.

Properties

Source: Merck

| . |

. |

| Description |

0.2 μm sterile filtered, Suitable for 3D bioprinting applications |

| Form |

Viscous liquid |

| Impurities |

≤5 CFU/g Bioburden (Fungal)

≤5 CFU/g Bioburden (Total Aerobic) |

| Color |

Colorless to pale yellow |

| pH |

6.5-7.5 |

| Application(s) |

3D bioprinting |

| Storage temp. |

2-8 °C |

Application

Gelatin methacryloyl (GelMA) is a polymerizable hydrogel material derived from components found in the natural extracellular matrix (ECM). Its popularity in tissue engineering applications stems from its cost-effectiveness, abundance, and the preservation of natural cell binding motifs.

Furthermore, the incorporation of photocrosslinkable methacrylamide functional groups into GelMA enables the production of biocompatible, biodegradable, and non-immunogenic hydrogels that remain stable under biologically relevant conditions. These hydrogels not only provide structural support but also foster crucial cellular processes such as adhesion, spreading, and proliferation.

The methacrylamide functional group offers not only rapid gelation but also the ability to regulate hydrogel physical properties, including pore size, degradation rate, and swell ratio. By modifying the degree of functionalization and polymerization conditions, precise temporal and spatial control of the crosslinking reaction can be achieved, enabling the creation of hydrogels with distinctive patterns, 3D structures, and morphologies.

Bioinks based on gelatin methacrylate (GelMA) have found application in the bioprinting of a wide range of tissues and constructs, including osteogenic, chondrogenic, hepatic, adipogenic, vasculogenic, epithelial, endothelial, cardiac valve, skin, tumor, and various other tissue types.

Packaging

10 ml bioink contained within a glass bottle.

Other notes

Some important tips for achieving optimal bioprinting results:

- Optimize printing: Customize printing parameters such as nozzle diameter, printing speed, printing pressure, temperature, and cell density to align with the specifications of your 3D printer and the requirements of specific applications.

- Reduce bubble formation. Air bubbles within the bioink can impede the bioprinting process. To prevent this, exercise careful handling of the bioink during mixing and transfer to minimize bubble formation. Avoid using vigorous vortexing or shaking techniques.

- UV light Crosslinking. For effective crosslinking, position the light source directly above the printed structure. It is important to note that lower-intensity light sources will necessitate shorter distances and longer exposure times to ensure thorough crosslinking. For optimal results, consider the following recommended conditions: Place an 800 mW/cm2 light source approximately 8 cm above the printed structure and expose it for 30 seconds.

Procedure

- Prepare bioink solution: To prepare TissueFab® - GelMA-UV bioink, warm it in a water bath or incubator set to 37 °C for approximately 30 minutes or until the bioink attains a fluid consistency. Afterward, gently invert the bioink to ensure it forms a homogeneous solution. It is crucial to avoid using vigorous vortexing or shaking techniques.

- Prepare bioink-cell solution: To prepare the bioink-cell solution, resuspend the cell pellet in the bioink solution at the desired cell density by gently pipetting it up and down. For extrusion-based bioprinting, a typical cell density ranges from 1 to 5 x 106 cells/mL. Once prepared, load the bioink-cell solution into the desired printer cartridge for the bioprinting process.

- Bioprint: To induce gelation, cool the filled printing cartridge to 15–19 °C using a temperature-controlled printhead or place the cartridge in a 4 °C environment for 10–15 minutes. If the 3D printer has bed temperature control, set it to 15 °C. Follow the instructions provided by the 3D printer manufacturer. Load the print cartridge onto the 3D printer and proceed to print directly onto a Petri dish or into multi-well plates. Make necessary flow adjustments based on nozzle diameter, printing speed, printing pressure, and temperature.

- Crosslink: Position the UV light source directly above the 3D-bioprinted structure and subject the structure to UV light at a wavelength of 365 nm. Ensure to adjust the distance settings and exposure times as specified by the specific bioprinter's requirements.

- Culture cells: Cultivate the bioprinted tissue using the suitable cell culture medium, adhering to standard tissue culture procedures.