Researchers reveal that edible, fast-dissolving pouches made from food byproducts could transform packaging, cutting plastic waste while keeping food fresher for longer.

Study: Edible Pouch Packaging for Food Applications—A Review. Image credit: bigacis/Shutterstock.com

Study: Edible Pouch Packaging for Food Applications—A Review. Image credit: bigacis/Shutterstock.com

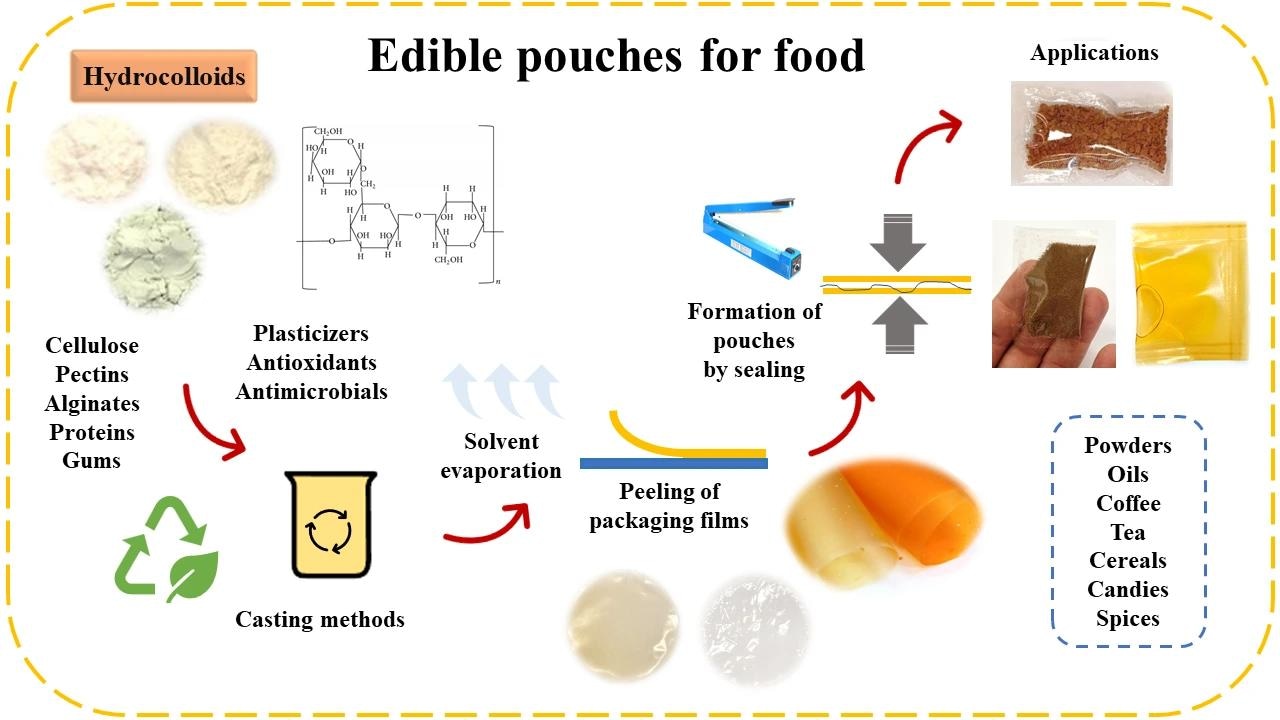

A recent review in Processes presents various aspects of edible food packaging, focusing on single-use, fast-dissolving edible pouches. Plastic food packaging, typically non-biodegradable, is a significant source of environmental pollution. Newer packaging systems are being developed, primarily based on biopolymers or multifunctional materials, to replace plastics and other synthetic polymers. Such edible coatings and films keep food fresh, intact, flavorful, and aromatic while maintaining their shelf life.

Introduction

About one-third of global food production goes to waste each year, amounting to roughly 1.3 billion tons valued at over $1 trillion. Better food packaging could help minimize spoilage, a major cause of food waste.

As practiced in ancient human history, natural food packaging included leaves, gourds, shells, and biodegradable grass, bamboo, or wood baskets. Later, pottery and glass jars came into use, and then paper.

About 150 years ago, plastic packaging was developed and has remained prominent until today. It is used in multiple methods of food preservation, such as modified atmosphere packaging, vacuum packaging, aseptic packaging, and active packaging. This keeps food from being contaminated and spoiled, locks in flavor, and maintains its appearance. It can also increase the attractiveness of the product.

However, the environmental cost of plastic has led to its fall in popularity among some consumers; hence, bioplastics are being developed. According to the European Bioplastics Organisation (EBO), these are plastics that are either bio-based (derived from renewable biomass) or biodegradable, though not always both.

Edible food packaging

Edible coatings are made of compounds Generally Recognized as Safe (GRAS) and produced through Good Manufacturing Practices (GMP). These are regulated under European and U.S. food safety frameworks, and edible packaging is subject to the same standards as food products.

Edible packaging aligns with aspects of the European Union’s Green Deal and related regulations, such as the EU’s 2020 Green Deal and Regulation 1935/2004, focusing on better local waste management, recycling, and reduced reliance on non-biodegradable plastics.

Edible coatings and films are either preformed or formed by drying the material on the food. These films may be made from edible polysaccharides, lipids, and proteins. The former (like cellulose and starch) are readily biodegradable, resist moisture, and provide an effective barrier against gases. Both polysaccharide and protein films (composed of gelatin or whey protein) make strong, flexible barriers, especially the latter.

Fats (such as waxes and fatty acids) also resist water entry but may feel greasy or fail to provide continuous films. Thus, it is important to choose the right polymer for the right application and the type of food to be protected.

Such packaging is also used for sachets that absorb moisture, carbon dioxide, and ethylene, preventing spoilage, puffing or rupturing of the packaging, and fruit over-ripening. The review notes that such systems contribute to a circular economy, and while EU strategies envision potential benefits for rural development, the direct impact of edible packaging remains unclear.

Other advantages include:

- Convenient dosing of foods, supplements, and medicines

- Compliance with dietary or medical recommendations

- Reduced packaging needs

- Easy storage and transportation

- Sustainability

- Environmental health

- Ease of administration

Edible packaging must be thick enough, resistant to light, moisture, and gases, and heat-stable. This is achieved by manipulating parameters like material concentration, plasticizer type, solvent composition, pH, temperature, and film thickness.

Data-driven methods could help design high-performing and more durable food coating materials more efficiently. Nanotechnology has led to the production of extremely thin protective coatings (on the scale of nanometers). Encapsulation is another method where hydrophilic or hydrophobic materials keep the substance of interest away from the exterior. This includes macro-, micro-, and nano-encapsulation.

Benefits of edible food packaging

Food packaging provides a barrier against gases and microbial contamination, inhibiting bacterial spoilage, rancidity, and other biochemical changes.

Additionally, edible packaging lowers the packaging-associated carbon footprint and reduces dependence on non-renewables. It also reduces the need to manage food packaging waste and lowers emissions of harmful products like chlorine, dioxins, and furans from plastic packaging material.

When made from byproducts of food production, they enhance manufacturing efficiency and profits. Compostable packaging is another advance, though this often requires specific conditions for complete breakdown.

The review highlights consumer perception and acceptance as critical factors. Concerns about flavor changes or contamination must be addressed, and some synthetic additives (like sulfites) used in packaging or preservation raise health concerns.

Examples of edible pouches for instant coffee, oil, seeds and dried cherry tomatoes

Water-soluble food coatings

One promising edible packaging format comprises disposable fast-dissolving food pouches made from renewable plant- or animal-origin materials. These may come as films, wraps, sachets, or coatings. They are applied directly to the food's surface, protecting it from environmental contact.

Thin, fast-dissolving films have been shown to perform well in various foods, from oils to meats. The review cites case studies: whey protein isolate films for instant coffee, soybean polysaccharide/gelatin films for coconut powder, corn zein films for cheese, and gelatin/chitosan blend for shrimp oil. These examples show both promise and technical trade-offs.

Three types of fast-dissolving technology are described, from oral thin films to compressed tablets and lyophilized systems.

Active vs intelligent packaging

Newer packaging is not just a mechanical coating but much more. Both active and intelligent packaging are designed to monitor the product's condition and protect against adverse outcomes.

Active packaging incorporates compounds for a controlled food environment, without adding them to the food itself. These molecules may remove oxygen, water vapor, ethylene, carbon dioxide, and certain odors. They may also release regulators like antioxidants or preservatives, or maintain an acceptable temperature range. Importantly, these substances are not added to the food itself.

Intelligent packaging is the outcome of biosensors and other sensors incorporated into the packaging to monitor food quality and safety, through parameters like the pH, carbon dioxide, oxygen, bacterial compounds, or toxins.

Download your PDF copy now!

Conclusions

While current policies discourage single-use forms of conventional plastics, environmentally friendly single-use biodegradable fast-dissolving edible packaging is a promising avenue, especially when produced from underutilized food components.

Active packaging goes beyond preventing contamination. It monitors oxidation, temperature, packaging conditions, and expiry dates to improve the food's consumer profile.

Using fast-dissolving food pouches, especially those that dissolve in contact with water, may introduce a scalable food packaging revolution. These can serve single servings of dry foods and instant drinks. Such packaging is also friendly for oils and powders, exploiting the efficiency of packaging, package removal and disposal, and the convenience of this formulation.

However, the review stresses that challenges remain, such as improving mechanical strength, ensuring moisture and oxygen barriers, gaining regulatory approval, and convincing consumers of safety and quality.

“Edible pouch packaging, made from safe and edible materials, provides a biodegradable option that decomposes naturally, thereby reducing pollution and the need for disposal.”