In this interview, Richard Chung, Product Manager at Wyatt Technology, discusses the development of the DynaPro Plate Reader 4, a next-generation system designed to bring powerful light scattering capabilities to standard well-plate formats. He explains how the instrument’s intuitive DYNAMICS Touch interface, integrated camera, and automation compatibility are helping streamline workflows, improve data quality, and support advanced applications in biotherapeutic development and nanoparticle formulation.

Can you tell us about your role at Wyatt Technology and your involvement in the development of the DynaPro Plate Reader 4?

I’ve been with Wyatt Technology for about nine years now. I started my journey in customer support, helping scientists and our users with method development and troubleshooting. All of that customer feedback and interactions gave me a deep understanding of how people use our instruments in the real world. When I transitioned into product management, I brought that perspective with me. With the DynaPro Plate Reader 4, I worked closely with engineering, customer beta testers and early adopters to modernize the platform, improve usability, and align it with our broader vision of accessible, high-performance instrumentation.

Image Credit: Wyatt Technology

Could you give us an overview of dynamic and static light scattering and why they’re useful in biotherapeutic development?

Light scattering is incredibly versatile. Dynamic light scattering (DLS) measures fluctuations in light intensity caused by particles undergoing Brownian motion, which we use to calculate hydrodynamic size. Static light scattering (SLS) gives us molecular weight and interaction parameters. These techniques are powerful tools across the drug development pipeline, whether screening for aggregation, assessing thermal or colloidal stability, or optimizing formulations. Aggregation often impacts immunogenicity, so detecting it early is critical.

What unmet needs did you want the DynaPro Plate Reader 4 to address?

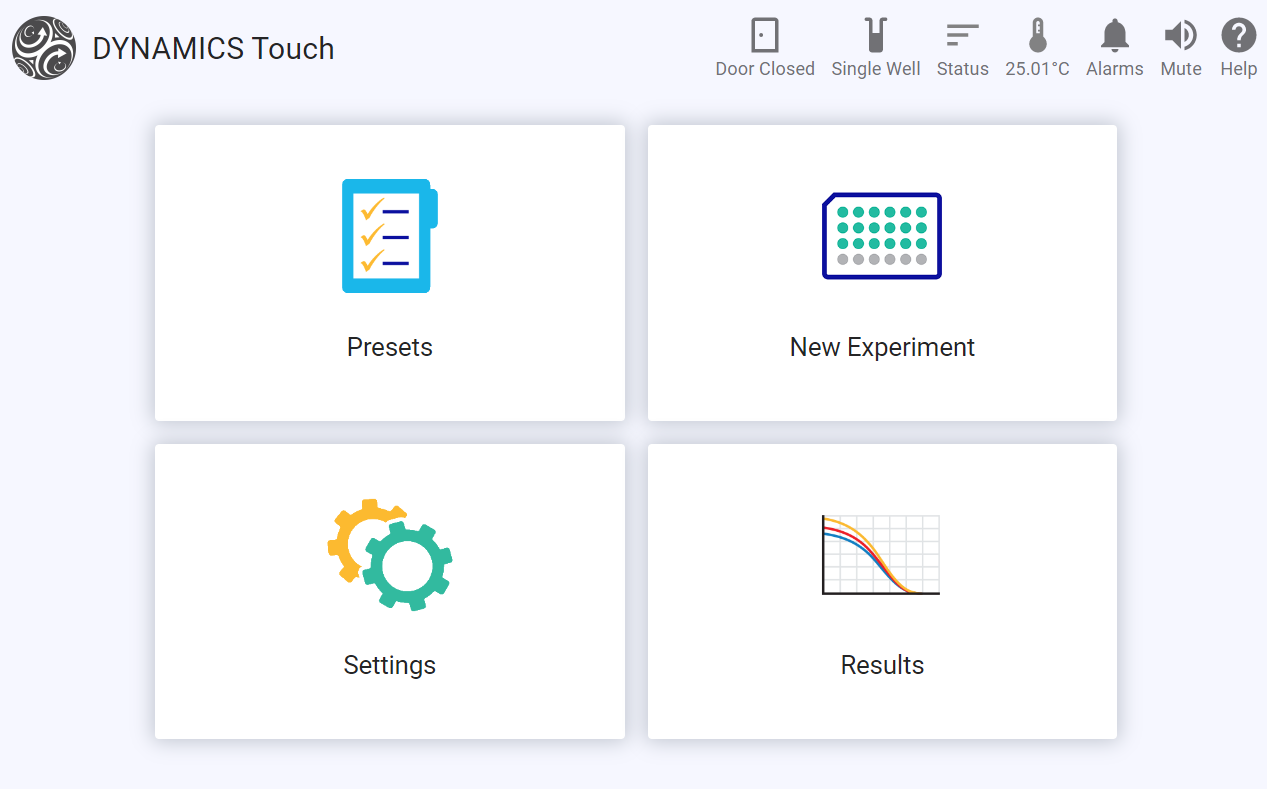

We wanted to modernize the instrument and make it easier to use, especially for newer or infrequent users. The DYNAMICS Touch interface was a big part of that - offering walk-up usability and simplified experiment setup. One of our beta testers runs a core lab that serves academic and pharma scientists to do their own proof-of-concept experiments. They told us the walk-up analysis was a game-changer and made it incredibly easy to set up experiments and get results immediately. That kind of feedback reinforced our focus on usability and helped shape features like customizable presets and real-time data quality checks.

Compared to competing technologies, our ability to measure DLS and SLS in industry-standard well plates (96, 384, and 1536 formats) really sets us apart. It makes the system ideal for high-throughput workflows and easy to integrate into existing lab setups. Since light scattering is a non-destructive test, a user can probe samples for size and polydispersity on an industry-standard plate and then move them to another instrument for additional characterization.

What are some of the key applications of the Plate Reader 4 in biotherapeutic development and nanoparticle formulation?

The Plate Reader 4 is a flexible platform that adapts to various research needs. It has DLS and SLS capabilities and a wide temperature control range, supporting a wide range of applications. We can assess aggregation under different conditions to optimize formulations, run colloidal stability studies with a concentration series using kD and A2, and perform thermal stability and freeze-thaw analysis thanks to our broad temperature range (4 °C to 85 °C). You can gain insights into unfolding and aggregation by analyzing molecular weight and hydrodynamic diameter across temperature ranges. We’ve even seen customers use the system for time-based studies for vaccine stability and viscosity estimation by spiking samples with known standards.

Can you explain the role of the DYNAMICS Touch interface and how it simplifies the user experience?

DYNAMICS Touch has a touchscreen interface that lets you build experiments from scratch directly on the touchscreen for walk-up measurement. You can also load a preset built by an expert user in the DYNAMICS desktop software. This makes it a lot easier for more novice users to run a method, or for a more experienced scientist to design a method and have it executed by a junior scientist. It’s also easy to change which wells you select in a preset with just a few taps of the touchscreen. We’ve also incorporated several new features that help users assess data quality in real time with live autocorrelation function monitoring and an integrated camera view. For example, if there are large particles in a sample, they will often cause high count rates or baselines. The system flags those samples so the user can look at them more closely. It’s all about making the system intuitive and reducing the learning curve.

Image Credit: Wyatt Technology

What role does the onboard camera play in ensuring data quality and diagnostics during measurements?

Combined with software diagnostics and data quality indicators, the camera helps users trust their data and troubleshoot issues more effectively. The onboard camera visualizes each well, helping identify bubbles, dust, or extremely large aggregates or precipitation that could interfere with measurements. Users can save these images and review them later if the system flags a measurement as suboptimal.

How does the instrument support GMP compliance and regulated environments?

Our desktop software, DYNAMICS, is 21 CFR Part 11 compliant. It includes audit trails, customizable user groups, and permission controls. We typically stabilize the platform for new instruments like the Plate Reader 4 before rolling out compliance features. We expect to roll out full GMP support for the Plate Reader 4 in early 2026.

How important was compatibility with robotic liquid handlers and lab automation systems during development?

It was extremely important. Labs are under pressure to increase productivity and analyze more samples in less time; automation is a key part of that. The Plate Reader 4 has an API available for purchase that allows integration with systems from companies like HighRes Bio, Hamilton, Labman automation and Waters’ Andrew + to name a few. Since Waters acquired Wyatt in May 2023, we’re also exploring ways to expand our automation capabilities even further and bridge the integration beyond what we’ve offered for automation packages in the past.

How do you see the future of light scattering evolving, and where does Wyatt Technology fit into that vision?

The goal is always to get the safest, most effective drugs to patients sooner. We’re seeing a push toward automation, cloud-based data environments, and multi-attribute analysis, always driving towards better efficiency and more data. A few of our customers are experimenting with self-driving labs using AI and machine learning, and we want our platforms to be part of that evolution. That kind of customer feedback is key to shaping the future of Waters | Wyatt. On the hardware side, we’re focused on smart integration - adding capabilities that complement existing workflows and provide a more complete picture of sample stability. It’s about maximizing the platform’s capabilities and enabling seamless data transfer across systems in a scientifically sound and user-friendly way.

About Richard Chung

Richard Chung is a Product Manager at Wyatt Technology, bringing years of expertise in light scattering and analytical instrumentation. Since joining Wyatt in 2016, he has held key roles, including Application Scientist and Customer Support Manager, where he worked closely with researchers to solve complex analytical challenges. Now, as a Product Manager, Richard bridges the gap between scientists and better instruments - gathering insights from the field and collaborating with internal research teams to develop cutting-edge solutions that empower laboratories worldwide.

About Waters | Wyatt Technology

Wyatt Technology Corporation, acquired by Waters Corporation in May 2023, develops instrumentation, software and techniques for the characterization of macromolecules and nanoparticles, in solution, based on light scattering and related technologies. The physical properties determined by Wyatt’s products include absolute molar mass of proteins, polymers and other macromolecules; size and charge (zeta potential); protein-protein and other biomolecular interactions; composition of conjugated proteins and co-polymers; and macromolecular conformation.

Waters Corporation, a global leader in analytical instruments, separations technologies, and software, focuses on accelerating the benefits of pioneering science to improve human health and well-being. For over 65 years, we have partnered with our customers to ensure the safety of the medicines we take, the purity of food we eat and the water we drink, and the quality and sustainability of the products we use every day.

Products and services

Wyatt’s product line includes instruments and software for:

- on-line multi-angle light scattering (MALS), used in conjunction with size-exclusion chromatography to quantify absolute molar mass, size, conformation, conjugation and aggregation

- traditional (cuvette-based) and high-throughput (microwell plate-based) dynamic light scattering (DLS) to determine size (radius) and size distributions, protein melting temperature and stability-indicating parameters

- electrophoretic mobility (PALS) to determine molecular charge/zeta potential

- composition-gradient light scattering for label-free analysis of biomolecular interactions

- field-flow fractionation for separation of macromolecules and nanoparticles from 1-1000 nm, used in conjunction with on-line light scattering and other detection technologies to quantify molar mass and size

Wyatt also offers, on a limited basis, sample analysis services utilizing its unique technologies.