Solenoid pumps and Fluid Metering pumps are two popular options for microfluidic management. This article examines their key differences across various application scenarios, highlighting which is better suited to different project requirements.

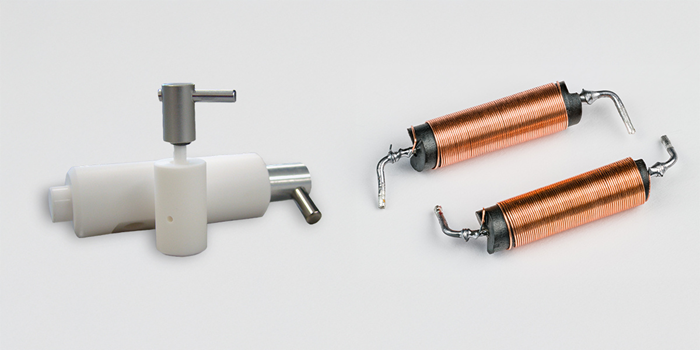

Image Credit: Fluid Metering, Inc.

Round 1: Precision and Reliability

The key difference between solenoid pumps and Fluid Metering pumps lies in their operating mechanisms.

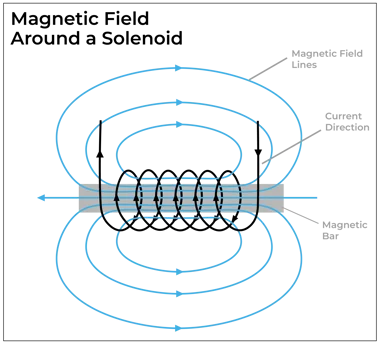

Solenoid pumps are driven by an electromagnet made up of a copper wire coil wrapped around a metal plunger. When electrical current flows through the coil, it creates a magnetic field that moves the plunger up and down, assisted by a spring.

In contrast, Fluid Metering pumps use a motor to drive a rotating, reciprocating piston to deliver fluid.

Image Credit: Fluid Metering, Inc.

Results

A solenoid pump’s internal valves are predisposed to clogging, resulting in pump seizures and compromised precision. The solenoid’s springs can also weaken and break with wear and tear, or they trap debris and contaminants. These factors adversely affect pump performance over time as the springs lose their tension.

Fluid Metering's pumps feature simpler, valveless designs able to prevent clogging while ensuring long-term reliability.

Their high-precision Cerampump® construction and patented adjustment method also afford Fluid Metering pumps the necessary boost to achieve more precise fluid delivery while enabling more accurate and consistent fluid dispensing versus solenoid pumps.

Round 2: Flow Rate Ranges

Solenoid pumps can achieve a range of flow rates depending on their size, typically from a few milliliters per minute to a few liters per minute. Fluid Metering pumps generally offer flow rates ranging from a few milliliters per minute to just over 1 liter per minute.

Results

When it comes to flow rate ranges for microfluidic applications, solenoid and Fluid Metering pumps may seem evenly matched at first glance. However, solenoid pumps need to be manufactured in different sizes to accommodate various flow rates.

In contrast, Fluid Metering pumps can cover a wider range of flow rates with a single pump, eliminating the need to use multiple pumps for different flow requirements.

Round 3: Pulsation Levels

Solenoid pumps inherently produce significant pulsation due to their spring-plunger design. While Fluid Metering pumps also generate some degree of pulsatile flow, there are several effective system modification strategies that can be used to help minimize this pulsation.

Results

The high and unavoidable pulsation levels produced by solenoid pumps make them unsuitable for certain applications. In contrast, the pulsation levels in Fluid Metering pump systems can be significantly reduced, allowing for smoother operation.

Round 4: Fluid Compatibility

Solenoid pumps are generally manufactured from standard plastics and rubber diaphragms, while Fluid Metering pumps boast a ceramic construction that is chemically inert.

Results

Solenoid pumps offer only limited chemical compatibility. They typically struggle with viscous fluids due to increased flow resistance and internal valve clogging. Fluid Metering pumps, however, can handle harsh chemicals more effectively, including fluids of varying viscosities.

Round 5: Long-Term Maintenance

Solenoid pumps require regular valve inspections and frequent diaphragm replacements to maintain proper operation and prevent clogging. Fluid Metering pumps, by comparison, deliver 0.5 % precision over millions of cycles without the need for maintenance or recalibration.

Results

Solenoid pumps tend to have a lower initial cost, but their ongoing maintenance requirements and potential for downtime increase costs while yielding a lower lifespan of just a few years.

Fluid metering pumps require little to no maintenance; however, they have an extended lifespan generally equal to or longer than the life of the instrument in which they are installed. This makes Fluid Metering pumps a more cost-effective option in the long run.

Summary

Solenoid pumps can be designed to accommodate similar flow rates, but Fluid Metering pumps can handle wider ranges with the same pump, making them the ideal choice for applications requiring reliable precision, high accuracy, long life, chemical inertness, and the ability to pump viscous fluids at high pressure.

Acknowledgments

Produced from materials originally authored by Thomas Breitenstein from Fluid Metering, Inc.

About Fluid Metering, Inc.

Fluid Metering, Inc. (FMI) is a worldwide leader in life science pumps and dispensers, having pioneered the first valve-less piston pump over 64 years ago. With specialized expertise in fluidics and applications, Fluid Metering, Inc. supports instrument developers in tackling complex fluidic challenges.

Committed to innovation through collaboration, Fluid Metering, Inc. advances health, sustainability, and quality of life. ISO 9001:2015 certified.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.