Sponsored Content by Vitrek LLCReviewed by Maria OsipovaSep 18 2025

Nuclear and particle physics, often referred to as high-energy physics, is a fundamental category of experimental physics. Various experiments in this field are classified as scattering experiments, where an incident particle strikes a target and the resulting scattered particles are studied. Scattering processes can involve particle creation or annihilation.

Image Credit: Vitrek LLC

A contemporary approach to researching scattered particles employs particle detectors, which detect individual particles impinging upon them.

This device provides an efficient and economical solution for performing particle experiments by combining high-speed data acquisition with signal processing.

This article first reviews common instruments used for data collection in particle-counting applications and then explains how the GaGe RazorMax Express CompuScope digitizer/oscilloscope can be used to create and store resulting data.

Figure 1. Examples of photo-multiplier tubes, or PMTs. Image Credit: Hamamatsu

Gathering the data

Researchers typically utilize photomultiplier tubes (PMTs) and semiconductor detectors in modern particle-counting applications. This is a fundamental first step in data collection for particle experiments.

As shown in Figure 1, PMTs are sensitive detectors of light photons that impinge upon their photocathode. When detecting photons, a scintillator material is usually placed in front of the PMT. The scintillator transforms sub-atomic particles into light photons, which the PMT then detects. This allows the PMT to act as a detector for a broad range of particles.

Semiconductor detectors (Figure 3) are employed in numerous applications instead of PMTs. Like PMTs, they generate an electrical pulse when struck by a particle. Pulse durations range from several nanoseconds to a few microseconds, with pulse amplitude proportional to the particle’s incident energy.

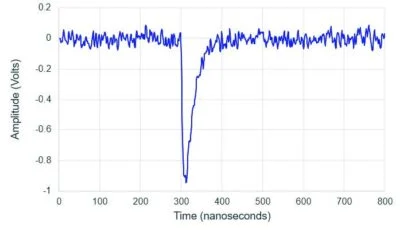

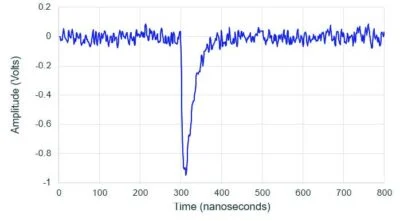

Fig 2. The graph depicts a typical negative-polarity sub-microsecond pulse that is output by a PMT. Image Credit: Vitrek LLC

Analyzing the data

The multichannel analyzer (MCA) is the primary tool for PMTs and semiconductor detectors that generate energy-proportionate output pulses.

In pulse height analysis (PHA) mode, the MCA displays a histogram (Figure 4) showing the number of detected particles versus pulse amplitude, which is proportional to particle energy.

The histogram in Figure 4 depicts pulse numbers (counts), similar to those of Figure 2, that have been detected at a given amplitude, plotted as “Channel Number.” The diagram exhibits a peak at just under Channel 1500, with a rising count at low channels, corresponding to background noise.

Beyond complex processing such as coincidence detection, particle experiments inherently demand versatile, reconfigurable instrumentation compared to other applications. This need from nuclear and particle physics led to the development of modular instrumentation, which refers to instruments that fit into a platform providing common electrical power, compactness, and streamlined interconnection.

Fig 3. Example of a semiconductor detector. Image Credit: Leybold

The nuclear instrumentation module (NIM) was an early standardized modular platform, supplying common AC and DC power to NIM instrument modules. Subsequent platform standards, including CAMAC and VXI, added digital communication between instrument modules and a host computer, enabling instrument configuration, control, and data recovery. Modern PCs with PCI Express (PCIe) slots for modular device cards are the successors of modular platforms such as CAMAC.

GaGe RazorMax express compuscope: Advantages

The GaGe RazorMax Express CompuScope digitizer/oscilloscope (Figure 5) provides functions equivalent to those of MCAs and other conventional modular instruments — but at a more affordable price. All particle-processing algorithms can be executed as digital signal processing (DSP) on digital waveform data captured by the instrument’s CompuScope.

A key advantage of the GaGe RazorMax Express CompuScope digitizer/oscilloscope, when compared with an MCA or conventional instrument module, is that the digitizer can preserve all raw particle pulse waveforms. For instance, this data can be utilized to detect and eliminate multi-pulse events.

Fig 4. Diagram of a typical display output from a multi-channel analyzer. Image Credit: Vitrek LLC

The RazorMax Express also offers a “Complex Triggering” mode, a unique advantage for particle experiments. In this mode, trigger events from all channels are Boolean “OR”ed together to create the final trigger event. This allows triggering to occur whenever a particle enters any one of multiple detectors connected to the CompuScope. The scheme can be extended across multiple CompuScope boards by linking their Trigger Out and Trigger In connections.

Fig 5. Vitrek’s GaGe RazorMax Express Compuscope 161G4. Image Credit: Vitrek LLC

The RazorMax Express can be operated with GaGeScope, GaGe’s flagship software. This software provides an oscilloscope-like interface from which the CompuScope can be operated without computer programming.

Although GaGeScope does not provide the particle counting display, analysis, or the control of other devices needed for a complete particle counting system, it offers robust Software Development Kits (SDKs). These kits enable users to develop custom software applications in C, LabVIEW, MATLAB, Python, and other languages on Windows and Linux platforms.

Application example: Digitizer operation in a nuclear and particle system

For instance, consider a user with four PMTs and associated conditioning electronics. The PMTs generate broad pulses approximately 1 microsecond wide, but require the system to operate with faster detectors. The system will be used for multiple experiments with unique configurations and count rates.

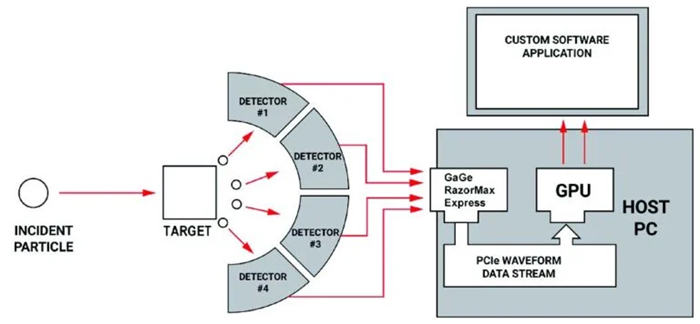

Fig 6. Atomic particle counting system uses a GaGe RazorMax Express to acquire the detector pulses. Image Credit: Vitrek LLC

The user selects the GaGe RazorMax Express CompuScope 161G4, which provides four input channels to digitize the four PMT signals. Additional RazorMax Express cards can be included for higher channel counts. When an incident particle strikes a target, the resulting particles enter four detectors located at certain angles.

The four channels on the RazorMax Express card in the host PC acquire these pulses. Data from the four channels is then streamed to a GPU card for rapid processing and reduction, then transferred to a custom software application via a Gage SDK sample program.

At 1000 MS/s, the RazorMax Express captures one sample per nanosecond, supporting pulse widths as short as 10 nanoseconds. Its 16-bit vertical ADC resolution allows operation in “Multiple Record Mode,” which acquires short ~1 microsecond records. An interval shorter than 1 microsecond is required to re-arm the RazorMax Express, enabling count rates as high as 500 kHz.

In “Streaming Mode,” data is directly transmitted to the PCIe bus and streamed into PC RAM memory. When sampling continuously across all four channels, the RazorMax Express generates an 8 GB/s data stream, equal to the theoretical maximum of a Gen 3 X8 PCIe bus. In practice, users will acquire no more than half the time, resulting in a data maximum of 4 GB/s.

Waveform data can be streamed to DSP algorithms on the host PC, stored on high-speed drives for later analysis, or streamed to a GPU card. To yield optimal results, algorithms can reduce raw waveform data in real time, and the DSP can be monitored and modified.

In various applications, triggers are generated at known intervals. “Time Stamp” values are critical in particle physics experiments for determining inter-particle detection intervals or average count rates.

Time Stamps are appended to the end of each Multiple Record waveform within the data stream, providing the arrival time of each particle pulse with nanosecond-level precision. The counter frequency can be disciplined with an external 10 MHz reference frequency if absolute timing is required.

Conclusion

With its robust streaming software and triggering capabilities, the Gage RazorMax Express CompuScope digitizer/oscilloscope enables researchers to build an affordable measurement system for various nuclear and particle experiments.

About Vitrek LLC

Since 1990, Vitrek has provided innovative global solutions for high voltage test and measurement including electrical safety compliance testers, multi-point high voltage switching systems and graphical power analyzers. The recent acquisition of MTI Instruments expands their test and measurement portfolio to include non-contact measurement devices, portable signal simulators and calibrators, semiconductor/solar metrology systems and turbine engine/rotating machine balancing. The acquisition of DynamicSignals’ portfolio adds a wide array of board-level data acquisition and integrated real-time RF record/playback system solutions from GaGe, KineticSystems and Signatec. Vitrek also supplies precision high voltage measurement standards to national laboratories and calibration labs around the world. This unique and complementary combination of product and engineering capabilities positions Vitrek as a leading provider of test solutions serving the photovoltaic, medical equipment, power conversion, electrical/electronic component, semiconductor, aerospace and appliance industries. Vitrek is an accredited ISO 17025 Calibration Laboratory.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.