Sustainability is a widely discussed topic, and for good reason. Long-term environmental responsibility is essential for future generations, and sustainability has been a core principle at Air Products for many decades.

From a practical perspective, sustainability is critical when planning, designing, or managing a cryogenic laboratory. Improving sustainability raises important questions: how can laboratories become more sustainable, why does it matter, and what benefits can be achieved?

Sustainability and why it’s important in the lab

One of the main benefits of sustainability is improved operational efficiency. Actions such as upgrading aging equipment or performing routine checks can reduce liquid nitrogen consumption, lower operating costs, streamline workflows, and improve sample security.

In addition, organizations seeking funding for laboratory improvements or expansion may find that a clear commitment to sustainability is a requirement within funding proposals. When forming partnerships, many organizations now expect collaborators to demonstrate similar environmental values.

For laboratories associated with universities or the National Health Service, sustainability targets must be met. In the case of the NHS, these expectations are outlined in the Sustainable Supplier Assessment. As environmental concerns continue to grow, additional regulations are likely to be introduced, making compliance increasingly important.

This raises an important question: why are more research facilities not making these changes? Beyond limited awareness and a tendency to rely on familiar practices, the primary barrier is often the perceived upfront cost. However, improving sustainability does not necessarily require significant investment and can lead to meaningful cost savings.

The right equipment

As a leading supplier of liquid nitrogen and cryogenic freezing equipment in the United Kingdom, Air Products frequently observes the consequences of poorly designed cryogenic rooms and unsuitable equipment choices.

Having the correct equipment in place is one of the most impactful steps a laboratory can take. Sustainable equipment is generally easier to operate, requires less energy and liquid nitrogen, enhances sample security, and delivers greater long-term value.

The most effective approach is to consider the entire installation and ensure it is appropriately matched to operational needs.

For example, one customer experienced an increase in liquid nitrogen top-ups and initially considered installing a larger external tank. This would have required additional space, increased rental costs, and more frequent deliveries.

Air Products instead recommended addressing the issue at the freezer level by upgrading to the equipment that consumed less liquid nitrogen. This allowed the customer to retain the existing tank, reduce delivery frequency, and improve sample protection.

Freezer upgrades

For laboratories able to specify new equipment or plan upgrades, several options are available, including models from the MVE range:

MVE HEco™ series: High-efficiency, environmentally friendly cryogenic freezers designed for vapor storage at –190 °C. These systems maximize storage density, enhance sample security, and significantly reduce liquid nitrogen usage.

MVE Vario™ series: A widely used alternative to ultra-low temperature freezers, suitable for cryogenic storage and offering extended hold times of up to 96 hours. These freezers provide stable temperature performance and meaningful cost savings compared with mechanical systems.

When evaluating freezers, it is important to consider both storage capacity and liquid nitrogen consumption. Similar to evaluating a vehicle based on fuel efficiency, the same principle applies to cryogenic freezer performance.

How much difference does switching freezers make?

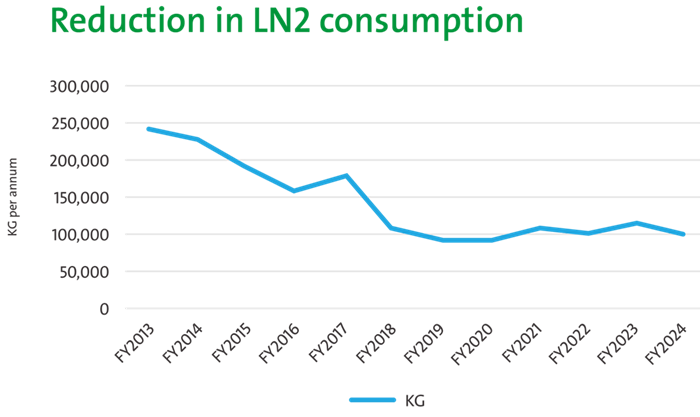

This chart illustrates how one customer, a national blood transfusion service, reduced liquid nitrogen consumption by more than 50 percent. The number of deliveries required was also significantly reduced.

Image Credit: Air Products PLC

Even if upgrading equipment is not currently possible, forward planning is essential. Selecting the right equipment in the future can lower operating costs and support compliance with evolving environmental regulations.

Other measures

There are additional ways to reduce liquid nitrogen consumption and improve sustainability, such as optimizing cryogenic room layout or reducing the distance between freezers and liquid nitrogen storage.

If these changes are not feasible, several other measures can still deliver meaningful improvements.

Small steps to sustainability

Sustainability improvements often result from a series of small, consistent actions. Many of these align with best practice recommendations, and when applied regularly, they can significantly reduce liquid nitrogen usage. This leads to fewer tanker deliveries and lower fuel consumption.

Examples of routine checks and actions include:

Monitoring equipment performance

Understanding how much liquid nitrogen equipment consumes is essential. Support is available from the Air Products team if assistance is needed.

Inspecting seals and lids

Damaged seals and ice buildup are common causes of excess liquid nitrogen loss and should be addressed promptly.

Checking hoses

Braided hoses experience greater stress due to temperature fluctuations. If replacement is required, vacuum-insulated hoses offer improved pressure stability and reduced losses.

Inspecting SIVL lines

SIVL lines may occasionally require re-vacuuming. Condensation on the line indicates reduced vacuum performance.

Inspecting LN2 tanks and freezers

Frost on external surfaces can indicate leakage or vacuum loss and should be investigated.

Optimizing freezer filling

How you fill your freezers can greatly affect how much LN2 is wasted. Filling freezers individually requires repeated cooling of the pipeline. Using a sequential filling approach, known as the daisy-chain method, minimizes liquid nitrogen waste.

Managing manual decant systems

Frequent use of pipeline decant systems increases cooling losses. Filling a 50-liter dewar and decanting from it can be a more efficient alternative.

While each action may appear minor on its own, collectively they can result in substantial savings over time and support long-term sustainability goals.

In conclusion

Although sustainability may not be the highest priority for every laboratory, following the steps outlined above or consulting with a specialist can make it an integral part of cryogenic operations.

From reducing liquid nitrogen consumption and improving efficiency to meeting regulatory requirements, sustainability offers both operational and financial benefits.

Even if major investments are not currently possible, early planning is essential. Sustainability-related upgrades will eventually be required, and delaying preparation can result in suboptimal decisions.

The Air Products team brings extensive experience in sustainability, efficiency improvement, and the supply of high-quality, safe equipment and gases. Air Products is also the only manufacturer in the United Kingdom offering MDR-certified liquid nitrogen.

Acknowledgments

This article was produced using materials originally authored by Jessica Davies at Air Products.

About Air Products PLC

Air Products touch the lives of consumers around the globe in positive ways every day. With approximately 16,000 employees and operations in 50 countries, we serve customers across a wide range of industries from food and beverage to medical, energy, and transportation. We supply a unique portfolio of atmospheric and process gases, equipment, and services.

Founded in 1940, Air Products has built a reputation for its innovative culture, operational excellence, and commitment to safety and the environment. Our passionate, talented, and committed employees from a diversity of backgrounds are driven by Air Products’ higher purpose to create innovative solutions that benefit the environment, enhance sustainability and address the challenges facing customers, communities, and the world.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.net, which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.