A compressor fails. A sensor does not trigger an alarm. Even just a simple power cut. For many sample storage centers or laboratories, this presents the nightmare scenario of vital samples deteriorating in just a few hours.

It can be easy for laboratory or storage center workers to think that this will not happen to them. In Massachusetts in 2012, however, the Harvard Brain Tissue Resource Center lost 147 samples because of a freezer failure; in 2019, a Los Angeles hospital similarly lost 56 stem cell samples from child cancer patients; and in December 2023, the Karolinska Institute in Sweden lost decades worth of research samples due to their freezer malfunctioning.

These are only a few examples of how quickly and easily things can go wrong. What many people in the lab sector do not realize is that there are solutions available that help to significantly mitigate the risks, greatly improving the safety of samples.

The role of the lab freezer

Air Products takes the view that the company sells insurance, rather than freezers. For medics, patients, and research teams, the security of vital samples is of utmost importance. The choice of lab freezers plays a crucial role in this. It is essential, therefore, to consider several key factors – not just opting for what has always been used or what is recommended – which can impact not only sample security but also the sustainability, efficiency, and operational costs of a laboratory.

Mechanical vs cryogenic

For temperatures as low as -20 °C, mechanical freezers are highly reliable and the least complicated method. At temperatures as low as -80 °C, Ultra Low Temperature (ULT) mechanical freezers can be used; however, they become increasingly complex and unreliable. If storage is required at temperatures of -135 °C or lower, ULT freezers are complex and prone to failure; liquid nitrogen storage proves to be the simplest and most reliable option.

Rethinking your sample storage

When considering different options, it is essential to view the larger picture rather than focusing solely on the temperature capabilities of the various types of freezers. In terms of infrastructure, ULT storage requires a complex electrical distribution system (high voltage, with emergency power generation potentially provided by an expensive backup generator, which also requires ongoing maintenance); a highly enhanced HVAC system; backup specimen storage in case of emergencies; and highly qualified service technicians.

Conversely, liquid nitrogen storage requires only standard electricity, low-level room extraction rather than HVAC, and battery backup power. It does, however, require a supply of liquid nitrogen (whether derived from dewars or a bulk pipeline), and oxygen depletion alarms.

The option Air Products recommends

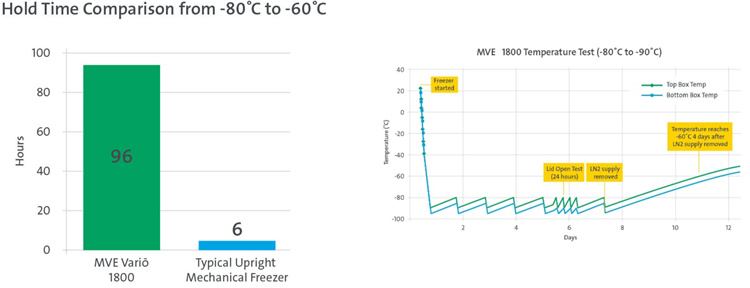

Many lab technicians may be used to using mechanical ULT freezers in their lab. When comparing the two, however, it is clear that liquid nitrogen storage has multiple advantages over ULT. Its simplicity, with minimal moving parts, no compressors, and no additional HVAC requirements, makes it a highly reliable system. Most importantly, its long freezer hold times of up to 96 hours increase safety margins, ensuring uninterrupted preservation and providing users with significantly more time to act if anything goes wrong.

Image Credit: Air Products PLC

If one decides to opt for liquid nitrogen, further questions emerge as to which freezer should be chosen. Air Products has found that MVE’s Variō series offers multiple benefits, as well as improved sample security. It is best suited to facilities with multiple freezers in one room (ideally on the ground floor next to an external wall).

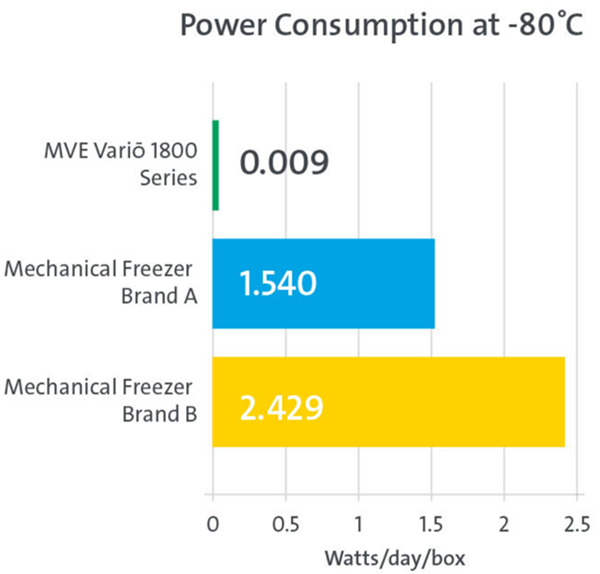

The most energy-efficient ULT freezer available

To begin with, it is highly energy-efficient, using just 1 % of the power required for mechanical freezers, thereby reducing users’ carbon footprints and saving approximately 70 % in operating costs.

Image Credit: Air Products PLC

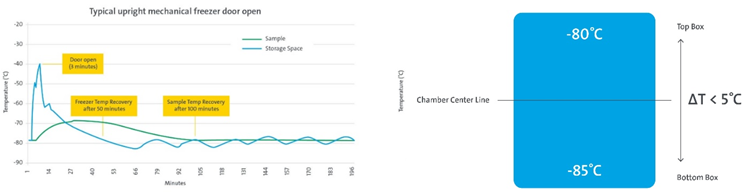

The Variō also offers an exceptionally uniform temperature profile, providing stable and consistent conditions throughout the freezer with no hot spots, even when the lid is opened, thanks to advanced insulation technology and rapid temperature recovery. In addition, storing liquid nitrogen in the freezer ensures that samples are stored in a dry, inert atmosphere, with a far lower chance of icing, when compared to mechanical freezers.

Image Credit: Air Products PLC

Versatility, efficiency, and capacity

Unlike mechanical freezers, the MVE Variō series is designed to operate over a wide temperature range, from -20 °C to -150 °C, with a conversion kit available to transform it into a high-efficiency freezer capable of temperatures as low as -190 °C. This flexible temperature control, combined with reduced energy consumption, and no need for special HVAC systems, make it an extremely cost-effective and versatile solution.

In many clinics, labs, and biobanks, space can be scarce. Variō freezers, however, offer much higher sample storage capacity per cubic meter when compared to mechanical designs, maximizing storage efficiency with an innovative design that optimizes internal storage configuration to store more samples in the same footprint.

In summary

Mechanical freezers have been the industry standard for many years, and it is clear to see why. However, when one considers just how many components have the potential to fail – not to mention the extra strain they can put on electrical systems and HVAC – these freezers cannot match the reliability and simplicity of liquid nitrogen ULT freezers when considering sample security. When considering running costs, sustainability, lab efficiency, and storage space, choosing the correct option becomes simple.

Acknowledgments

Produced from materials originally authored by Stephen Robinson from Air Products.

About Air Products PLC

Air Products touch the lives of consumers around the globe in positive ways every day. With approximately 16,000 employees and operations in 50 countries, we serve customers across a wide range of industries from food and beverage to medical, energy, and transportation. We supply a unique portfolio of atmospheric and process gases, equipment, and services.

Founded in 1940, Air Products has built a reputation for its innovative culture, operational excellence, and commitment to safety and the environment. Our passionate, talented, and committed employees from a diversity of backgrounds are driven by Air Products’ higher purpose to create innovative solutions that benefit the environment, enhance sustainability and address the challenges facing customers, communities, and the world.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.net, which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.