One of the primary responsibilities of a fertility clinic is the safe storage of collected samples. However, many clinics rely on backroom spaces where every available square inch is occupied by dewars holding valuable samples.

It has become clear that situations like those shown in the images below are not uncommon in fertility clinics across the United Kingdom.

Image Credit: Air Products PLC

Dewars are often stored in ways that increase risk due to poor access, manual liquid nitrogen filling, and random monitoring. With narrow walkways, numerous trip hazards, and alarm wiring running across limited space, staff health and safety can also be compromised.

Image Credit: Air Products PLC

At the heart of the issue is that many fertility clinics are running out of space.

The rapid growth of fertility clinics in the United Kingdom

Fertility clinics are under increasing pressure due to the growing demand for their services.

Approximately one in seven couples in the United Kingdom, representing around 3.5 million individuals, experience difficulties conceiving naturally. The number of fertility treatment cycles has continued to rise, reaching 80,000 cycles in 2023, representing a 13 percent increase from 2022.

At the same time, National Health Service-funded IVF cycles in England declined by 17 percent between 2019 and 2022, with a 36 percent reduction in Wales. As a result, more patients are turning to private fertility clinics.

Social factors have also contributed to increased demand. The freezing of eggs, sperm, and embryos has risen significantly as individuals choose to have children later in life or preserve fertility for medical reasons. In July 2022, regulations were updated to allow storage periods of up to 55 years, compared with the previous limit of 10 years.

Image Credit: Air Products PLC

While this growth presents significant opportunities for fertility clinics, it also places substantial pressure on facilities to find additional cryogenic storage space.

Finding space where there is none

For many clinics, finding additional space is increasingly challenging. Town and city center locations, while convenient for patients, often restrict expansion due to limited physical space and high rental costs.

Many clinics continue to rely on traditional dewar-based storage methods, which may have been suitable in the past but are no longer adequate for the volume of samples now being handled. In addition, splitting samples across multiple dewars to reduce the risk of catastrophic loss can further strain already limited capacity.

As a result, situations arise where rooms are filled with manually filled dewars, each capable of holding only a limited number of samples. With a continued growth forecast, this problem is expected to intensify.

In such circumstances, a fundamental rethink is required to enable more samples to be stored within the same footprint. This is where specialist support can prove invaluable, drawing on broad knowledge of available options and how they can be adapted to individual clinic requirements.

Ways to increase capacity

Many clinics are surprised by how much additional storage capacity can be achieved within the same floor space. There are now far more solutions available to maximize sample storage than many clinic teams realize.

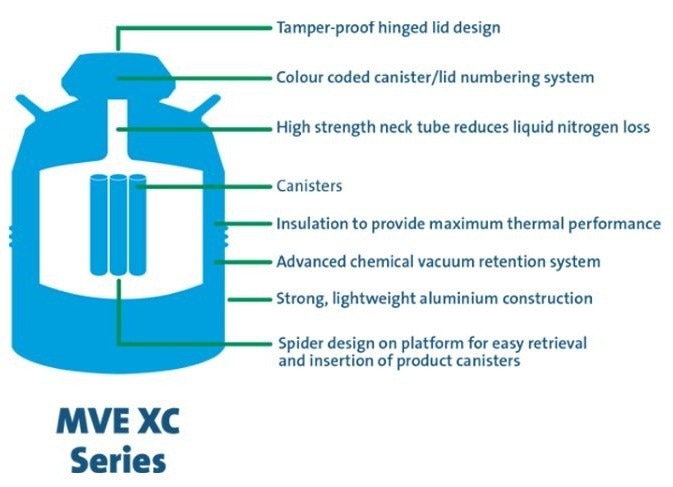

Features XC-series

- Portability

- Low liquid nitrogen consumption

- Convenient lightweight package

- Optional Roller Base

Image Credit: Air Products PLC

For example, switching to high-capacity dewars can allow clinics to store significantly more straws than before. Air Products often recommends the MVE XC Series, which offers capacities of up to 5,000 straws.

Moving to larger freezers is generally preferable, and several options are available. Recent installations include the MVE CryoSystem 6000FA in a Scottish hospital that previously used cryoboxes for sperm storage.

This system can also be adapted with racks suitable for straw storage. The MVE 816P-2T, designed specifically for the IVF market, uses a two-level configuration to store thousands more straws, while the MVE 616 can accommodate up to 63 taller canisters to increase goblet storage capacity.

These larger systems are typically more efficient and feature integrated alarms and automatic filling. This eliminates exposed wiring and removes the need to transport liquid nitrogen through rooms, corridors, elevators, or stairwells. Most importantly, these systems are designed to make optimal use of available space.

Image Credit: Air Products PLC

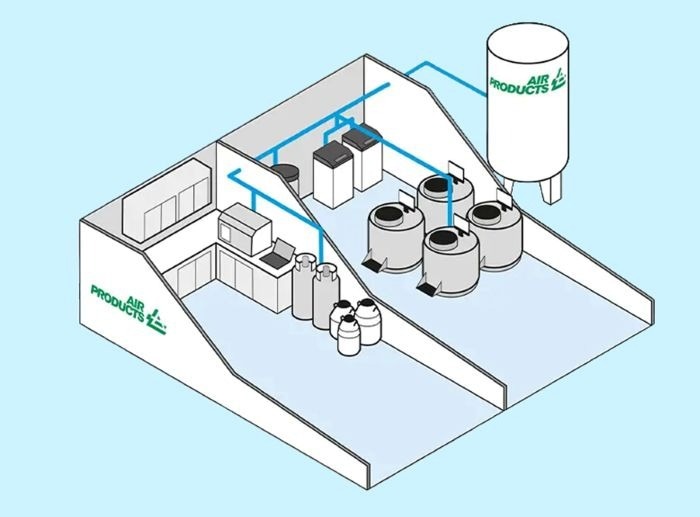

While relocating to larger premises may not be feasible, reassessing the layout of an existing facility can deliver meaningful improvements.

Relocating a cryogenic storage room closer to an external liquid nitrogen tank with suitable delivery access can support a more efficient installation. This enables the use of larger, high-efficiency freezers, reduced pipework, and storage solutions suited to both current and future needs.

Changing your cryoroom layout or moving it to another room in the same premises can significantly improve efficiency. Image Credit: Air Products PLC

The example shown illustrates a recent installation that demonstrates how appropriate MVE freezer selection can increase capacity while improving the working environment.

Image Credit: Air Products PLC

Ask the experts

Although increasing demand points to a strong future for fertility clinics, it is essential to act now to ensure cryogenic storage systems can scale effectively.

Every clinic is different, and there is no one-size-fits-all solution. Air Products works closely with leading manufacturer MVE to provide a wide range of cryogenic freezers in multiple configurations.

This enables a thorough assessment of premises, location, and both current and future requirements, ensuring the most effective solution is recommended to optimize space utilization and operational efficiency, as has been done for IVF clinics across the country.

Acknowledgments

This article was produced using materials originally authored by James Ryan at Air Products.

About Air Products PLC

Air Products touch the lives of consumers around the globe in positive ways every day. With approximately 16,000 employees and operations in 50 countries, we serve customers across a wide range of industries from food and beverage to medical, energy, and transportation. We supply a unique portfolio of atmospheric and process gases, equipment, and services.

Founded in 1940, Air Products has built a reputation for its innovative culture, operational excellence, and commitment to safety and the environment. Our passionate, talented, and committed employees from a diversity of backgrounds are driven by Air Products’ higher purpose to create innovative solutions that benefit the environment, enhance sustainability and address the challenges facing customers, communities, and the world.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.net, which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.