Most of the time, only minimal volumes of the sample are available for particle size analysis. Typically, in catalysis and pharmaceutical industries, particle size analysis needs to be conducted at initial stages of product development, when the available quantity of the material to be analyzed is only a few milligrams. In such cases, reliable measurements on minute sample volumes are required, and the sample needs to be retrieved for further analysis.

Method Development for Small Sample Volumes

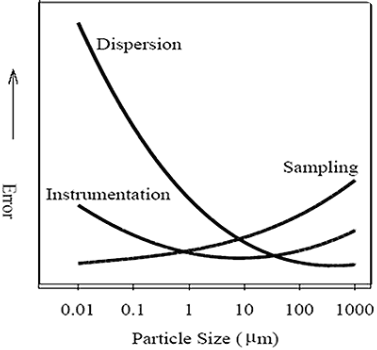

Obtaining repeatable results is the main challenge faced in laser diffraction measurements using small sample volumes. It is important to control the sampling of the material and dispersion so as to acquire relevant data. Achieving control, especially when only a minute quantity of material is available for method development and analysis, can be challenging. Users usually control sampling by choosing a representative sample. This often results in erroneous results in the measurement of large particles, as shown in Figure 1.

Figure 1. Sources of error as a function of particle size in laser diffraction

A representative result can be acquired only when a minimum number of particles are measured. For instance, a minimum of 400 particles need to be measured to achieve 5% standard error on the Dx (90). This sets an upper limit of approximately 200µm for the particle size that can be determined using small volume dispersion units like the Hydro SV.

Selecting an appropriate dispersant and stir rate and applying external sonication, control over dispersion can be achieved. The major source of error in fine particle measurements is dispersion

(Figure 1). The Hydro SV consists of a 6-7ml cuvette with magnetic stirrer. This wet dispersion unit allows continuous circulation of the sample through the measurement zone in order to perform multiple measurements. Direct observation of the suspension of the sample in the cuvette is possible. The sample suspension can also be determined by analyzing the data trends. The sample can be recovered by decanting the contents of the cuvette at the end of the analysis.

Case Studies

In order to highlight the capabilities of the Hydro SV, the dispersion of a fine sample as well as the sampling of a comparatively coarse material need to be tested. To test the dispersion of Hydro SV, a micronized lactose sample was considered, as it was fine and so dispersion was challenging. Quantification of a pigment consisting of larger particles was performed in order to show that a small volume dispersion unit is capable of producing reproducible results with good sampling.

Dispersion Results

Measurement of the micronized lactose sample was performed in its as-received condition and after being subjected to sonication. Due to lack of an internal ultrasound, an external ultrasound by means of a sonic bath was applied to reduce the volume of the cuvette in the Hydro SV.

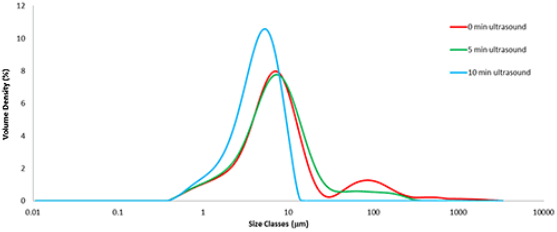

The as-received micronized lactose sample was observed to be agglomerated, which is shown in Figure 2. A decrease in the particle size was observed after the first period of sonication; however, agglomerates continued to be present. In order to disperse agglomerates completely and obtain stable results, the sample was sonicated further.

Figure 2. Particle size distributions from fine grade lactose measured with 0, 5 and 10 minute applications of ultrasound

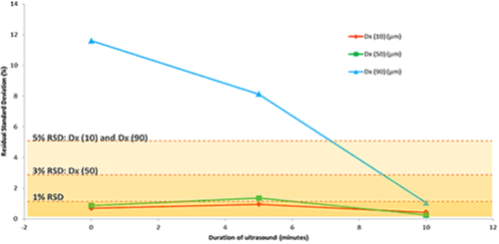

Figure 2 depicts the average particle size distributions resulting from five repeat measurements taken at individual points in the dispersion process. Figure 3 shows that as the period of sonication is increased, the relative standard deviation is decreased.

The instability of the dispersion is indicated by the variations before and after a five-minute period of sonication. After a ten-minute period of sonication, the variation falls between the acceptable ranges, as per the ISO standard. The reduction in variability and the narrowed particle size distribution indicate the complete dispersion of the sample.

Figure 3. Relative standard deviation, %, vs duration of ultrasound, minutes. The measurement repeatability is less than 1% for the Dv10m Dv50 and Dv90 once the sample is fully dispersed.

Reproducibility and Repeatability of Hydro SV

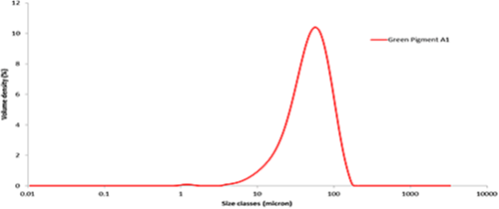

In order to demonstrate that a small volume dispersion unit can produce reproducible results with good sampling, a green pigment consisting of larger particles was chosen for measurement. The characteristic particle size distribution of the pigment is depicted in Figure 4. The chosen sample was large enough to be quantified in the Hydro SV, with a Dx (90) of nearly 100µm. In materials with such particle sizes, incidences of error occur mostly during sampling, as illustrated in Figure 1.

Figure 4. The average particle size distribution obtained from aliquot A1 of green pigment.

The stir speed for the Hydro SV should be chosen appropriately for samples consisting of larger particles in order to maintain the sample in suspended condition and to pass a representative sample of the material through the cuvette’s measurement zone.

The recommended stir speed for most of the powder samples ranges between 1500 and 1800rpm. Based on the size distribution statistics acquired from six measurements of one aliquot of the pigment, the repeatability of the measurements is observed to be within the limits prescribed by the ISO for laser diffraction.

The reproducibility of the measurements is illustrated by the size distribution statistics acquired from six aliquots of the pigment. The quality of the chosen sampling method has a profound effect on the reproducibility of the results. As per the data, the reproducibility obtained using the Hydro SV is well within the ISO limits, which is a result of good sampling.

Conclusion

A number of chemical and pharmaceutical applications require routine measurements to be carried out on small sample volumes during the initial stages of product development. The Hydro SV is a suitable system for such measurements due to its ability to produce repeatable and reproducible results using very small sample volumes.

References

- Dr Henk Merkus “Quality Assurance in Particle Size Measurement” from Improving Standards in Particle Size Distribution Measurement, February 17-19, 1997, at the Engineering Research Centre for Particle Science and Technology.

- ISO 13320:2009 “Particle Size Analysis – Laser Diffraction Methods”.

About Malvern Panalytical

Malvern Panalytical provides the materials and biophysical characterization technology and expertise that enable scientists and engineers to understand and control the properties of dispersed systems.

These systems range from proteins and polymers in solution, particle and nanoparticle suspensions and emulsions, through to sprays and aerosols, industrial bulk powders and high concentration slurries.

Used at all stages of research, development and manufacturing, Malvern Panalytical’s materials characterization instruments provide critical information that helps accelerate research and product development, enhance and maintain product quality and optimize process efficiency.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.