The production of beer via brewing involves a multitude of different steps, with control of fermentation being key. The environment that fermentation occurs in must be tightly controlled to ensure that the beer produced is of the intended quality.

The different parameters that must be controlled include the type of yeast used, the sugar composition, the temperature at which fermentation occurs and the solution pH. (Grassi et al., 2013)

Using spectrometers for NIR and full wavelength analysis is of benefit to the brewing process for the following reasons:

- NIR analysis can be used to analyze barley and malt crops, as they are grown, for monitoring of breeding and to screen if a crop is ripe enough. (Halsey, 1987)

- “The analysis of the spectral response of vegetation through remote sensing could be a valid means to rapidly investigate and define overall plant health and nutritional status.” (Fluvià, 2015)

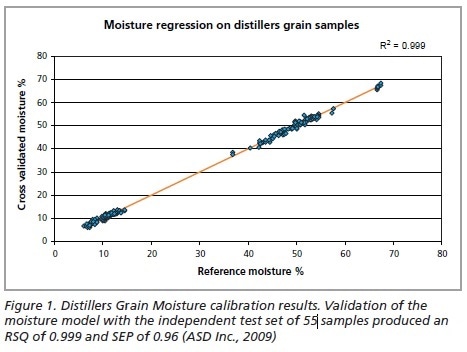

- Grain products used as animal feed can be analyzed using NIR. (ASD Inc., 2009)

- Ground hop samples can be analyzed using NIR to determine their α-acid, β-acid and oil content, moisture levels, and their expected hop storage index. (Halsey, 1987)

- The feedstocks for brewing (hops, yeast, malt, barley) can be tested for quality control using NIR analysis. (Valeria et al., 2012)

- The aging of alcoholic beers can be determined using NIR analysis (Ghasemi-Varnamkhasti et al., 2012)

- The production of ethanol is possible using many different sources of starch including potatoes, corn, barley and wheat. The starch levels of each of these sources can be analyzed using NIR to determine the volume of ethanol they will produce. (Fluvià, 2015)

Multivariate analysis, i.e. chemometrics, through quantitative calibration can also provide a number of advantages when producing beer and ethanol:

- Regression methods can be used to correlate NIR reflectance to different lab processes

- Calibrations can be set up for the analysis of different processes and components

- Unique calibrations can be ran for all stages of fermentation including grain analysis (protein, starch and moisture content), malting (protein content and overall quality), mashing (carbohydrate levels, fermentable carbohydrate analysis and wort parameters), fermentation (acid and soluble sugar content), production of animal feed (protein, fiber, sulfur and moisture content).

- Several different analyses can be ran from one measurement

- Dynamic quantitative analysis can be ran alongside ASD’s LabSpec® analyzer (GRAMS IQ; The Unscrambler®)

Systems for Analysis

Spectrometers provided by Malvern Panalytical are fast and highly sensitive, with a strong signal:noise ratio. With a wide spectral range, which reaches between 350 and 2,500 nm, they can be used for many different processing applications.

Systems from ASD are the perfect solution for the analysis of brewing and ethanol production processes:

Muglight is made for the absorbance and reflectance readings of raw materials.

LabSpec 4 provides high-specification measurements in a compact package allowing it to be used in the field, or on the lab bench. The system is made for quantitative applications.

Turntable is designed for the analysis of non-homogenous samples (where it can provide an average at high-accuracy) or for samples of irregular shape.

Malvern Panalytical ASD instruments are perfect for the brewing industry because:

- They do not damage the sample and are completely non-invasive

- Sample preparation is not required

- Data and analysis can occur in real time, perfect for in the field, and is fast and simple to carry out

- The system can be used in the lab, in the field or at-line

About Malvern Panalytical

Malvern Panalytical provides the materials and biophysical characterization technology and expertise that enable scientists and engineers to understand and control the properties of dispersed systems.

These systems range from proteins and polymers in solution, particle and nanoparticle suspensions and emulsions, through to sprays and aerosols, industrial bulk powders and high concentration slurries.

Used at all stages of research, development and manufacturing, Malvern Panalytical’s materials characterization instruments provide critical information that helps accelerate research and product development, enhance and maintain product quality and optimize process efficiency.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.