Why is it important to know about different methods of sample handling?

For the handling of specific sample types, certain techniques are more effective than others. To receive the best quality spectrum from a sample, it is crucial to establish which handling technique is best for any given sample type.

Securing the best available spectral data possible will boost your confidence in regard to your results.

Sampling techniques

Transmission

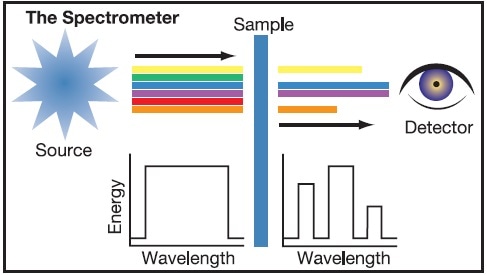

The transmission technique does not necessitate a separate accessory. The user just needs to position the sample directly into the infrared (IR) beam. As the IR beam goes through the sample, the energy transmitted is measured, a spectrum is then generated.

However, the analyst often needs to first prepare the sample into a pellet, mull, film, etc. prior to making the transmission measurement. This process demands expert handling and can be labor-intensive.

Conceptual diagram of the beam path through a transmission sample. Image Credit: Thermo Fisher Scientific – Materials & Structural Analysis

What types of samples can be analyzed?

Excellent quality spectra can be acquired for numerous types of samples using transmission. The transmission technique can be utilized alone or in combination with various accessories such as microscopes and liquid or gas cells to analyze:

- Liquids (free-flowing or viscous)

- Gases (high concentrations to trace amounts)

- Organic powders in pellet or mull form

- Thermoplastic powders

- Soluble polymers

- Dark polymer films (not carbon-filled)

- Thin polymer films

- Regular-shaped polymers (with preparation)

- Irregular-shaped polymers (with preparation)

What are the advantages of transmission?

- Economical: cells and mounts are not too expensive

- Excellent spectral information: perfect for qualitative measurements

- Ideal for quantitative work: several traditional operating procedures are based on transmission

- Well established: most conventionally used form of sample measurement

Attenuated total reflection (ATR)

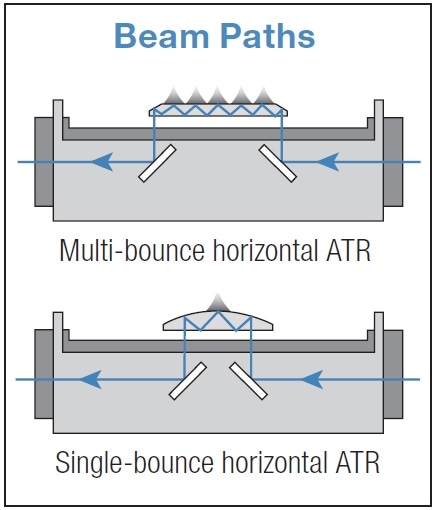

An ATR accessory functions by measuring the changes that take place in an internally reflected IR beam when contact is made between the beam and a sample. An IR beam is guided onto an optically dense crystal with a high refractive index at a specific angle.

This internal reflectance produces an evanescent wave that reaches beyond the surface of the crystal into the sample that maintains contact with the crystal. Where the sample absorbs energy in regions of the IR spectrum, the evanescent wave will be attenuated.

The attenuated beam returns to enter the crystal, departs at the opposite end of the crystal and is guided onto the detector in the IR spectrometer. The detector records the attenuated IR beam as an interferogram signal, which can then be utilized to produce an IR spectrum.

Image Credit: Thermo Fisher Scientific – Materials & Structural Analysis

What types of samples can you analyze?

ATR is perfect for samples that have strongly absorbing or densely thick characteristics which often yield intense peaks when measured by transmission.

ATR functions well for these samples due to the intensity of the evanescent waves that exponentially decay with distance from the surface of the ATR crystal that in general, makes the technique insensitive to sample thickness.

Other solids that are an appropriate fit for ATR include homogeneous solid samples, the surface layer of a multi-layered solid or the coating on a solid. Even irregular-shaped, hard solids can be analyzed utilizing a hard ATR crystal material, for instance, diamond.

Ideal solids include:

- Coatings

- Laminates

- Natural powders

- Paints

- Plastics

- Rubbers

- Solids that can be ground into powder

Additionally, ATR is the preferred method for liquid analysis as it necessitates just a drop of liquid to be placed on the crystal.

ATR can be employed to analyze:

- Biological materials

- Coatings

- Free-flowing aqueous solutions

- Viscous liquids

What are the advantages of ATR?

- Analysis of samples in their natural states – it is not necessary to heat, press into pellets or grind to acquire spectra

- Excellent for thick or strongly absorbing samples – perfect for difficult samples like black rubber

- Fast and easy cleanup – simply remove the sample and clean the surface of the crystal

- Minimal sample preparation – place the sample on the crystal and collect data

Diffuse reflectance (DRIFTS)

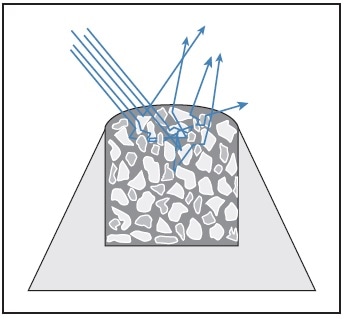

When focusing an IR beam onto a fine particulate material, the incident beam can interface with the particle in one of many ways. First, radiation can reflect off of the top surface of the particle without piercing the particle.

Second, the light can experience multiple reflections off particle surfaces without penetrating the particle. True diffuse reflectance comes from the penetration of the incident radiation into one or more sample particles and ensuing scatter from the sample matrix.

The IR beam interacting with a sample in a diffuse reflectance experiment. Image Credit: Thermo Fisher Scientific – Materials & Structural Analysis

A DRIFTS accessory functions by directing the IR energy into a sample cup that contains a mixture of the sample and an IR transparent matrix (such as KBr).

The IR radiation interacts with the particles and subsequently reflects off their surfaces. This causes light diffusion, or scattering, as it passes through the sample.

The output mirror then guides this scattered energy to the detector in the spectrometer. The detector registers the modified IR beam as an interferogram signal, which can then be utilized to produce a spectrum.

Commonly, a background is collected using the DRIFTS accessory in place and the cup filled with just the IR matrix. First-class quantitative and qualitative data acquisition is possible with the appropriate sample preparation.

However, transmission and ATR techniques are preferred to diffuse reflectance for quantitative data because of pathlength.

What types of samples can you analyze?

DRIFTS is frequently used for the analysis of both inorganic and organic samples that can be ground into a fine powder (less than 10 microns) and mixed in a powder matrix such as potassium bromide (KBr).

Typical sample types include:

- Hard polymers

- Rigid polymers

- Soft powders and powder mixtures

The DRIFTS technique can also be used in conjunction with silicon carbide paper for the analysis of large intractable surfaces. Silicon carbide paper is used to abrase a small amount of a variety of samples for analysis.

This technique is a workable alternative to conventional sampling techniques for paint and varnish surfaces, rigid polymers and tablets.

What are the advantages of diffuse reflectance?

- Fast and simple cleanup – dump the cup and blow or rinse clean

- Little to no sample preparation – just place in the sample cup

- No need for pressed KBr pellets or untidy mulls – samples can be run neat or diluted with KBr powder

True specular reflectance/reflection-absorption

How does it work?

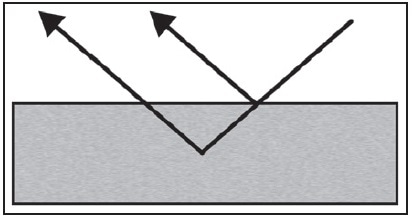

True specular reflectance is a surface measurement method that functions on the principle of reflective efficiencies. This principle establishes the fact that every sample has a refractive index that changes with the frequency of light to which it is subjected.

Diagram of the interaction of the beam using true specular reflectance. Image Credit: Thermo Fisher Scientific – Materials & Structural Analysis

Diagram of the interaction of the beam using reflection-absorption. Image Credit: Thermo Fisher Scientific – Materials & Structural Analysis

Rather than examining the energy that passes through the sample, true specular reflectance measures the energy that reflects off the surface of a sample or its refractive index.

By evaluating the frequency bands in which the rate of change in the refractive index is high, users can build a hypothesis in relation to the absorbency of the sample.

The true specular reflectance technique supplies exceptional qualitative data. Reflection-absorption functions on the same basis, but as a result of sample properties, some of the energy moves through the surface layer, absorbs into the bulk of the sample and then reflects off a substrate beneath the surface layer.

When criteria for both techniques are met, a combination of true specular reflectance and reflection-absorption can appear. If a qualitative comparison to transmission spectra is required, users can apply the Kramers-Kronig correction to the data to eliminate the effects of dispersion.

What types of samples can you analyze?

Specular reflectance is frequently used for the analysis of both organic and inorganic samples that possess large, flat, reflective surfaces. Reflection-absorption can appear when one of the above criteria is jeopardized and, just below the surface, the sample has a reflective substrate present.

This type of analysis is frequently used for laminated materials on metals, metallic surfaces, silicon wafers and thin films on reflective substrates.

What are the advantages of specular reflectance?

- Nondestructive analysis – no contact or sample damage when conducting analysis

- Sensitivity to monolayer samples – can identify Angstrom thick coatings on metal substrates

- Wide range of accessories available – can utilize main spectrometer and microscope accessories contingent on the thickness of the surface layer and the size of the sample

Source: Thermo Fisher Scientific – Materials & Structural Analysis

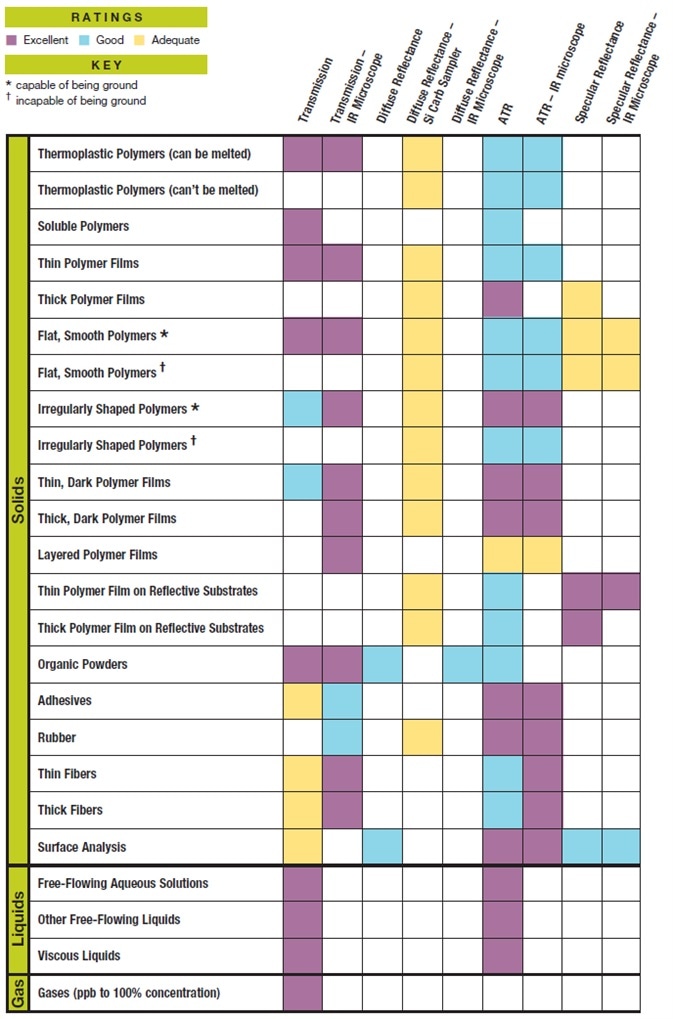

Index of sample types

Powders – solids (organic and inorganic) that can be ground into a powder (2–5 micron particle size); Examples: chemicals, pharmaceuticals, crystalline materials, pigments, fibers, polymers and powders

Thermoplastic Polymers – polymers that can be pressed into free-standing thin films

Soluble Polymers – polymers that can be cast as a thin film or dissolved in a solvent

Thin Polymer Films – free-standing polymer films that are not soluble or thermoplastic and are less than 50 microns thick

Thick Polymer Films – free-standing polymer films that are not thermoplastic or soluble and are more than 50 microns thick

Regularly Shaped Polymers – regularly shaped polymers, plaques and films that are hard or soft with a smooth surface, are not thermoplastic or soluble and are capable of being ground

Regularly Shaped Polymers – regularly shaped polymers, films and plaques that are hard or soft with a smooth surface, not thermoplastic or soluble and are incapable of being ground

Irregularly Shaped Polymers – irregularly shaped polymers that are hard or soft with a rough or irregular surface, capable of being ground, not thermoplastic or soluble. Examples include formed polymers, polymer beads and pellets

Irregularly Shaped Polymers – irregularly shaped polymers that are hard or soft with a rough or irregular surface, incapable of being ground, not thermoplastic or soluble

Thin, Dark Polymers – carbon-filled polymers high in inorganic content that are less than 10 microns thick and are not thermoplastic or soluble, such as carbon black

Thick, Dark Polymers – carbon-filled polymers high in inorganic content that are not soluble or thermoplastic and more than 10 microns thick

Layered Polymer Films – polymers that are comprised of two or more layers or thin or thick films, such as layered paints and packaging materials

Thin Polymer Film on Reflective Substrate – polymer film on any kind of surface that reflects IR energy (usually metal) that is under 15 microns thick, including lubricants on hard disk media and layers on silicon wafers

Thick Polymer Film on Reflective Substrate – polymer film on any kind of surface that reflects IR energy (usually metal) that is more than 15 microns thick. Examples: coatings on containers (such as soda cans)

Adhesives – solid adhesives such as tapes and solid glues

Rubbers – irregular-shaped rubber items that are not thermoplastic or soluble; Examples: o-rings, gaskets and fittings

Thin Fibers – thin and bundled fibers

Thick Fibers – thick and bundled fibers Surface Analysis – for qualitative analysis of the outermost layer of any solid or film

Free-Flowing Aqueous Solutions – liquids that contain any amount of water. Examples: inks, dyes, solvents and paints

Other Free-Flowing Liquids – liquids that do not contain water

Viscous liquids – thick liquids, emulsions and pastes. Examples include greases, polyols and heavy oils

Gases (ppb to 100% concentration) – any sample that is a gas at room temperature or just above room temperature

Smart accessories

Design elements to consider when choosing an accessory

Thermo Scientific appreciates the necessity for efficiency and reproducibility in today’s lab. By conducting extensive research, Thermo Scientific examined the features and benefits of users' demand in their sampling accessories.

This exhaustive process led to the development of unparalleled Thermo Scientific™ Smart Accessories™. These accessories provide the following value-added features:

- Automatic and fast purge – achieves purge up to three times faster than a conventional accessory

- Accessory recognition – identifies the accessory automatically as soon as it is put in place and records its serial number in a non-editable history file

- Accessory performance checks – tests the accessory to ensure that it is performing optimally

- Experiment setup – automatically sets up your experiment parameters so you can start sampling immediately

- Multi-media tutorials and online help – answers any questions you may have while conducting your analysis

- Permanently aligned optics – needs no optical adjustment, so results are reproducible and quantifiable

- Rugged design – protects optics from daily use and dust

- Spectral quality checks – examines data as it is collected and rates the quality of the spectra you have collected, offering suggested improvements when necessary

Thermo Scientific offers an extensive line of both Smart Accessories and basic sampling accessories to meet the needs of your laboratory. Additionally, the company offers a range of microscope objectives to facilitate the analysis of small samples.

About Thermo Fisher Scientific – Materials & Structural Analysis

Thermo Fisher Materials and Structural Analysis products give you outstanding capabilities in materials science research and development. Driving innovation and productivity, their portfolio of scientific instruments enable the design, characterization and lab-to-production scale of materials used throughout industry.

Thermo Fisher Materials and Structural Analysis products give you outstanding capabilities in materials science research and development. Driving innovation and productivity, their portfolio of scientific instruments enable the design, characterization and lab-to-production scale of materials used throughout industry.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.