Introduction

What Are Ultra-Processed Foods?

Key Ingredients in UPFs

Industrial Techniques Used in Manufacturing

Why Are UPFs Made This Way?

Global Supply Chain and Distribution

Health and Environmental Considerations

Regulatory and Industry Oversight

Final takeaways

Related Video

References

Behind every packet of snacks and instant noodles lies a story of engineered palatability, global supply chains, and rising chronic disease, understanding UPFs is critical for protecting health and the planet.

Introduction

In the United States, over 70% of the average adult's daily calories come from ultra-processed foods (UPFs).1,2 Ubiquitous in supermarkets, vending machines, and fast-food menus, UPFs are widely consumed by populations across both high-income and low-to-middle-income countries.

The growing association between UPFs and adverse health outcomes, their contribution to environmental degradation, and their reshaping of global dietary patterns emphasize the importance of elucidating what constitutes UPFs and how they are manufactured.

Image Credit: retan / Shutterstock.com

Image Credit: retan / Shutterstock.com

What Are Ultra-Processed Foods?

The widely used NOVA food classification system categorizes foods based on their nutrient content and the level of processing involved in their production.3 NOVA Group 1 includes unprocessed or minimally processed foods, such as whole grains, fruits, vegetables, and fresh meats with no or minimal alterations.

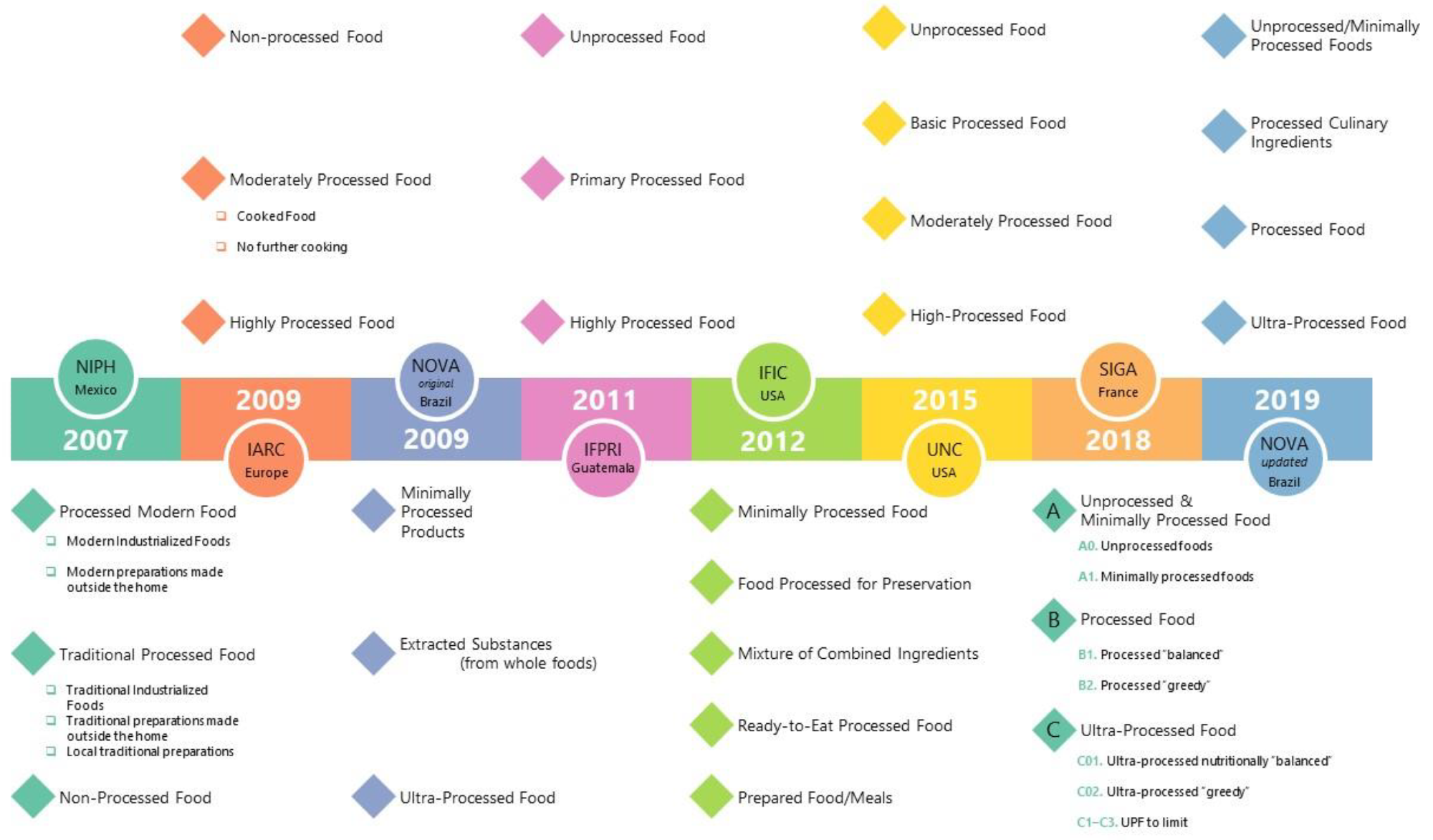

The timeline and summary of primary UPF food classification systems.10

The timeline and summary of primary UPF food classification systems.10

NOVA Group 2 foods include processed culinary ingredients, comprising substances extracted from foods, such as oils, sugars, and salt, used for cooking. Comparatively, Group 3 comprises processed foods that undergo some processing, such as cheese, canned vegetables, and baked goods.

Group 4 includes UPFs, which are industrial formulations manufactured using preservatives, artificial flavors, emulsifiers, and other additives that enhance taste and shelf life.3 Some examples of UPFs include sugar-sweetened beverages, packaged snacks, ready-to-eat meals, instant noodles, reconstituted meat products, and many breakfast cereals.

As compared to other types of processed foods, UPFs undergo more processing steps. Furthermore, the industrial intent behind the production of UPFs is to create products that are hyper-palatable, cost-effective, and designed for overconsumption.4

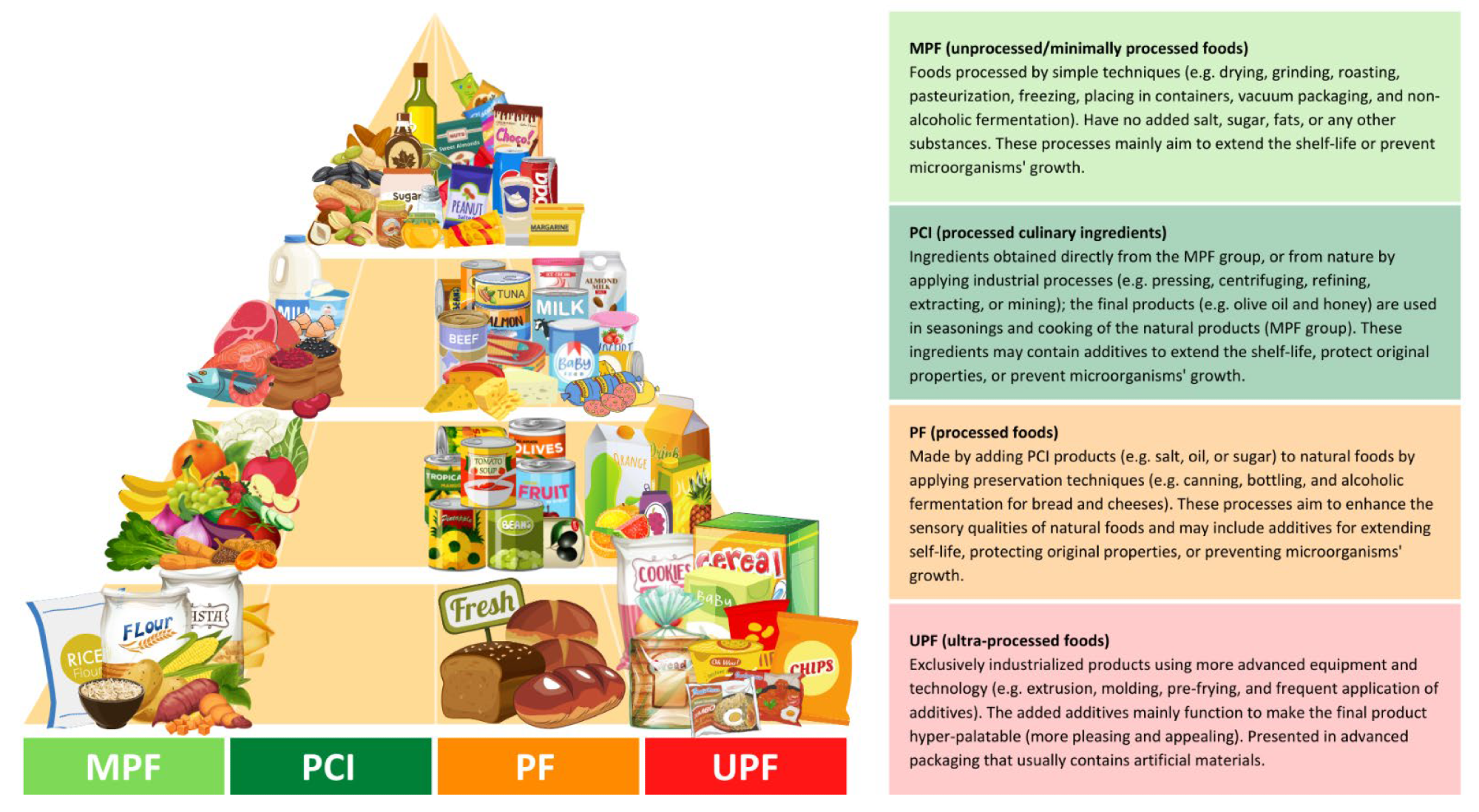

Distributed food examples in the food pyramid based on the NOVA classification. The different colors (light green, green, orange, and red) represent the degree of the processing; green colors (MPF and PCI) have the least level of industrial processing, orange (PF) has a modest level, and red (UPF) has the most extensive level. 11

Distributed food examples in the food pyramid based on the NOVA classification. The different colors (light green, green, orange, and red) represent the degree of the processing; green colors (MPF and PCI) have the least level of industrial processing, orange (PF) has a modest level, and red (UPF) has the most extensive level. 11

Key Ingredients in UPFs

UPFs consist of a wide range of industrial ingredients rarely found in home kitchens, some of which include refined starches and sugars such as maltodextrin, high-fructose corn syrup, and glucose syrup. These bulk ingredients and sweeteners are easily digested but devoid of fiber or micronutrients.1,5

Industrial fats and oils are also often incorporated into UPFs. Some examples of these include hydrogenated or interesterified oils, which contribute to texture and extend shelf life but may introduce trans fats and other compounds linked to cardiovascular disease into the body.5

Additives are also frequently used to produce UPFs and serve diverse roles, such as preservatives that extend shelf life, flavor enhancers like monosodium glutamate (MSG) that increase palatability, emulsifiers such as carboxymethylcellulose to help maintain texture and consistency, and food colorants to enhance visual appeal.

Many additives are lab-derived and approved for use within regulatory limits. For example, synthetic compounds, including artificial sweeteners, modified starches, and texturizers, are also typically used to create sensory profiles that resemble natural foods while allowing for low-cost mass production.5,6 Importantly, the long-term health effects of consuming these artificial ingredients remain unclear.6

Industrial Techniques Used in Manufacturing

The creation of UPFs involves a series of complex, mechanized techniques rooted in food engineering and sensory science.

Fractionation

Fractionation involves the deconstruction of whole foods into individual components such as proteins, fibers, and sugars. For example, soybeans may be fractionated into soy protein isolate, soy oil, and lecithin, each of which is used in different product lines.4

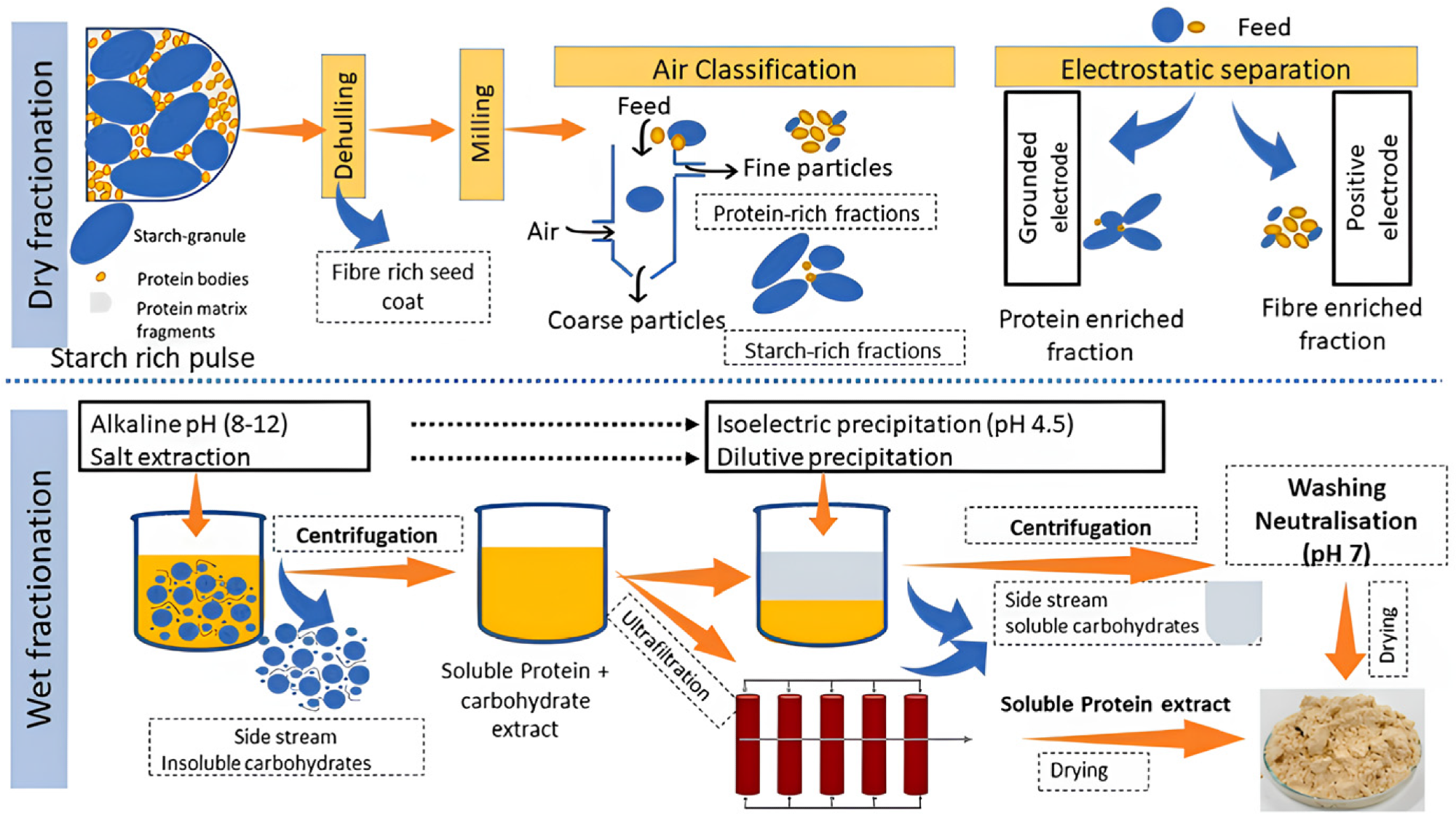

An overview of wet and dry fractionation techniques12

An overview of wet and dry fractionation techniques12

Reconstitution and formulation

Reconstituting fractionated components with additives and water is also used to form food-like substances. This process often involves precise formulations to achieve desired taste, texture, and appearance, thereby enabling consistency across massive production scales.1

Extrusion

Extrusion is a high-temperature and high-pressure process in which raw materials are forced through a die, then rapidly expanded and shaped to produce snacks and breakfast cereals. These processes determine product form while also affecting their digestibility and glycemic response.4

Hydrogenation and texturization

Both hydrogenation and texturization alter the physical properties of fats or proteins, such as converting vegetable oils into semi-solid forms for spreads or shaping plant proteins into meat analogs.1

Flavor science

Food technologists use algorithms and chemical modeling to mimic the flavor and mouthfeel of traditional foods. Food scientists often use ‘flavor pyramids’ that deconstruct flavor into distinct levels such as emotional perceptions, visual appearance, aromas, and textures to maximize consumer appeal and encourage repeat consumption.2

Read the latest research on ultra-processed foods

Why Are UPFs Made This Way?

The engineering involved in the production of UPFs is determined by interrelated economic, technological, and behavioral factors such as scalability and shelf stability, cost efficiency, consumer appeal, and targeted marketing.7

UPFs are designed to withstand long transportation and storage periods without spoilage, facilitating their global distribution and minimizing logistical costs. Moreover, the ingredients used in UPFs are typically derived from cheap agricultural commodities such as corn, soy, and wheat, which allows companies to produce high-profit-margin items at low cost.7

UPFs are also engineered to deliver ideal combinations of salt, sugar, and fat that stimulate dopamine-driven reward pathways and encourage habitual consumption. The packaging, branding, and convenience of UPFs further increase their marketability, especially among time-constrained consumers.

Children and adolescents are often the focus of aggressive advertising strategies for UPFs, which may exploit their psychological vulnerability to branded characters, cartoons, and social media influencers.8,9

Global Supply Chain and Distribution

The ingredients used to produce UPFs are sourced through a complex international supply chain of monoculture farms, industrial processors, and global trade networks. Large agribusiness and multinational food corporations dominate this industry and benefit from subsidies and the scale of the UPF economy.1

Once formulated, UPFs are packaged using advanced materials that limit oxygen and moisture exposure. These products are subsequently distributed through vast logistics networks, facilitated by efficient transportation and centralized warehousing systems. Retail partnerships and aggressive marketing ensure product visibility and placement of UPFs in both urban and rural markets worldwide.1

Health and Environmental Considerations

Numerous studies have linked high UPF consumption to a wide range of non-communicable diseases, including obesity, type 2 diabetes, cardiovascular diseases, and some cancers. These associations are largely due to nutrient dilution, such as loss of fiber, vitamins, and minerals, as well as high levels of added sugars, fats, sodium, chemical preservatives, and other additives.2

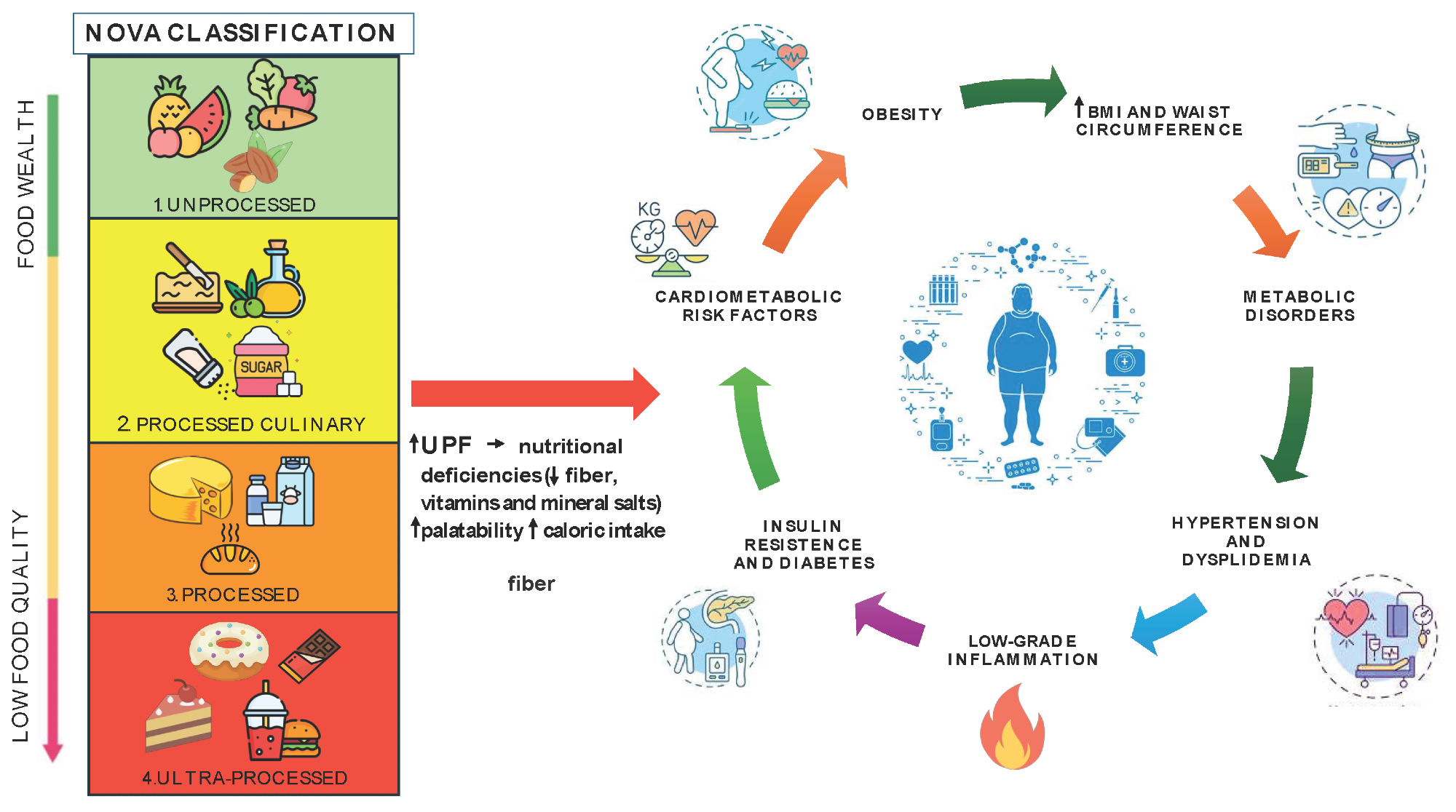

The relationship between UPF foods and obesity.13

The relationship between UPF foods and obesity.13

UPFs often have higher glycemic loads, lower satiety indices, and altered food matrices, all of which can disrupt normal satiety signaling and ultimately lead to passive overconsumption.4

The demand for commodity crops like corn and soy incentivizes unsustainable farming practices such as monoculture, which increases the risk of biodiversity loss and soil degradation. Furthermore, most UPFs are often stored in multilayered plastic packaging, which further contributes to environmental pollution and landfill overuse.8

Regulatory and Industry Oversight

Despite their known health implications, UPFs may escape stringent regulatory oversight due to gaps in labeling laws and the fragmented nature of food governance systems. For example, most modern nutrition labels highlight macronutrient content without providing details on the degree of processing of food products, which is a key determinant of health outcomes.1

Notably, the food industry has a long history of influencing public policy and research through lobbying and funding. This often results in delayed or weakly enforced regulations and consumer confusion around what constitutes “healthy” food.7

Final takeaways

UPFs are the result of sophisticated industrial processes that transform cheap agricultural inputs into highly palatable, long-lasting, and profitable products. Growing evidence confirms the direct relationship between UPF consumption and a wide range of chronic and life-threatening diseases. Thus, understanding how UPFs are made is essential for advancing public health goals, informing regulatory frameworks, and guiding consumer choices.

Despite the widespread availability of UPFs, a global counter-movement continues to advocate for minimally processed, whole-food-based eating patterns, such as the Mediterranean diet, that support both human and planetary health.

Related Video

UK doctor switches to 80% ULTRA-processed food diet for 30 days 🍔🍕🍟 BBC

References

- Monteiro, C. A., Cannon, G., Levy, R. B., Moubarac, J. C., Louzada, M. L., Rauber, F., Khandpur, N., Cediel, G., Neri, D., Martinez-Steele, E., Baraldi, L. G., & Jaime, P. C. (2019). Ultra-processed foods: what they are and how to identify them. Public Health Nutrition, 22(5), 936–941. DOI: 10.1017/S1368980018003762, https://www.cambridge.org/core/journals/public-health-nutrition/article/ultraprocessed-foods-what-they-are-and-how-to-identify-them/E6D744D714B1FF09D5BCA3E74D53A185

- Hall, K. D., et al. (2019). Ultra-Processed Diets Cause Excess Calorie Intake and Weight Gain: An Inpatient Randomized Controlled Trial of Ad Libitum Food Intake. Cell Metabolism, 30(1), 67–77.e3. DOI: 10.1016/j.cmet.2019.05.008, https://www.cell.com/cell-metabolism/fulltext/S1550-4131(19)30248-7

- Monteiro, C. A., Cannon, G., Moubarac, J. C., Levy, R. B., Louzada, M. L. C., & Jaime, P. C. (2017). The UN Decade of Nutrition, the NOVA food classification, and the trouble with ultra-processing. Public Health Nutrition, 21(1), 5–17. DOI: 10.1017/S1368980017000234, https://www.cambridge.org/core/journals/public-health-nutrition/article/un-decade-of-nutrition-the-nova-food-classification-and-the-trouble-with-ultraprocessing/2A9776922A28F8F757BDA32C3266AC2A

- Fardet, A., & Rock, E. (2020). Ultra-Processed Foods and Food System Sustainability: What Are the Links? Sustainability, 12(15), 6280. DOI: 10.3390/su12156280, https://www.mdpi.com/2071-1050/12/15/6280

- Visioli, F., et al. (2023). The ultra-processed foods hypothesis: a product processed well beyond the basic ingredients in the package. Nutrition Research Reviews, 36(2), 340–350. DOI:10.1017/S0954422422000117, https://www.cambridge.org/core/journals/nutrition-research-reviews/article/ultraprocessed-foods-hypothesis-a-product-processed-well-beyond-the-basic-ingredients-in-the-package/9BA1F88916DFBFD65A2D3D4C93ED867C

- Lane, M. M., Gamage, E., Travica, N., Dissanayaka, T., Ashtree, D. N., Gauci, S., Lotfaliany, M., O'Neil, A., Jacka, F. N., & Marx, W. (2022). Ultra-Processed Food Consumption and Mental Health: A Systematic Review and Meta-Analysis of Observational Studies. Nutrients, 14(13), 2568. DOI:10.3390/nu14132568, https://www.mdpi.com/2072-6643/14/13/2568

- Seferidi, P., Scrinis, G., Huybrechts, I., Woods, J., Vineis, P., & Millett, C. (2020). The neglected environmental impacts of ultra-processed foods. The Lancet. Planetary Health, 4(10), e437–e438. DOI: 10.1016/S2542-5196(20)30177-7, https://www.thelancet.com/journals/lanplh/article/PIIS2542-5196(20)30177-7/fulltext

- Muli, S., Blumenthal, A., Conzen, C. A., Benz, M. E., Alexy, U., Schmid, M., Keski-Rahkonen, P., Floegel, A., & Nöthlings, U. (2024). Association of Ultraprocessed Foods Intake with Untargeted Metabolomics Profiles in Adolescents and Young Adults in the DONALD Cohort Study. The Journal of Nutrition, 154(11), 3255–3265. DOI: 10.1016/j.tjnut.2024.09.023, https://www.sciencedirect.com/science/article/pii/S002231662401040X?via%3Dihub

- Wood, B., Williams, O., Baker, P., & Sacks, G. (2023). Behind the “creative destruction” of human diets: An analysis of the structure and market dynamics of the ultra‐processed food manufacturing industry and implications for public health. Journal of Agrarian Change, 23(4). DOI: 10.1111/joac.12545, https://onlinelibrary.wiley.com/doi/10.1111/joac.12545

- Nees, S., Lutsiv, T., & Thompson, H. J. (2023). Ultra-Processed Foods—Dietary Foe or Potential Ally? Nutrients, 16(7), 1013. DOI: 10.3390/nu16071013, https://www.mdpi.com/2072-6643/16/7/1013

- Almarshad, M. I., Algonaiman, R., Alharbi, H. F., Almujaydil, M. S., & Barakat, H. (2021). Relationship between Ultra-Processed Food Consumption and Risk of Diabetes Mellitus: A Mini-Review. Nutrients, 14(12), 2366. DOI: 10.3390/nu14122366, https://www.mdpi.com/2072-6643/14/12/2366

- Meenakshi Sundaram, G. S., Das, D., Sajeeb Khan, A., Zhang, L., & Meda, V. (2024). Developments in the Dry Fractionation of Plant Components: A Review. Separations, 11(12), 332. DOI: 10.3390/separations11120332, https://www.mdpi.com/2297-8739/11/12/332

- Monda, A., De Stefano, M. I., Villano, I., Allocca, S., Casillo, M., Messina, A., Monda, V., Moscatelli, F., Dipace, A., Limone, P., Di Maio, G., La Marra, M., Di Padova, M., Chieffi, S., Messina, G., Monda, M., & Polito, R. (2023). Ultra-Processed Food Intake and Increased Risk of Obesity: A Narrative Review. Foods, 13(16), 2627. DOI: 10.3390/foods13162627, https://www.mdpi.com/2304-8158/13/16/2627

Last Updated: May 9, 2025