Please can you give an overview of differential pressure sensors and how they have reduced in size over time?

When Sensirion developed the first generation of differential pressure sensors (SDP1108 series), size was not of the essence. Instead Sensirion showed that it could provide, with the thermal flow through technique, a differential pressure sensor which is superior in performance, especially for low differential pressures.

The second generation (SDP600 series) was already smaller but still larger in size than typical membrane based static differential pressure sensors. Nonetheless, for most applications small size was not an important requirement.

Today medical devices need to be more and more portable and mobile. To give you a few examples: for some diseases patients are today diagnosed at younger ages. This means they tend to travel more often and need or want to travel with their medical devices (for example oxygen concentrators).

Another use case for portable medical devices is that hospitals need to release patients earlier for cost reasons. The third category is simply that patient comfort is higher with lighter and portable devices. For example a patient who relies permanently on a portable ventilator is more flexible and can better participate in different activities.

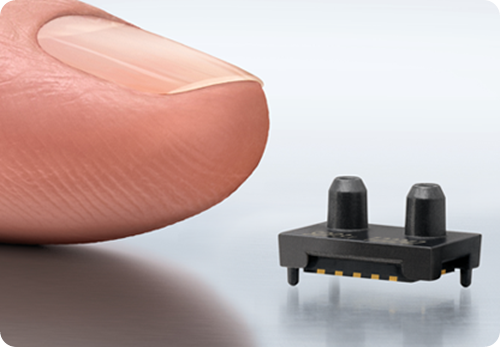

Additionally, we see that wearables are entering the medical device market. With all those use cases in mind, Sensirion developed the SDP3x, the third generation differential pressure sensor which is the smallest differential pressure sensor respectively flow sensor on the market.

In what ways was the size of differential pressure sensors previously limiting in terms of medical applications?

In the past differential pressure sensors were only one part of a larger device and other components for example turbines and batteries were much larger and heavier anyway. But when it comes to wearables and portable devices, size matters and the SDP3x provides new possibilities for applications and device integration the small size should create space for the ideas of our customers.

How small is the SDP3x sensor and what applications does this potentially open up?

The SDP3x differential pressure sensor measures just 5mm x 8mm x 5mm (0.2 x 0.3 x 0.2 inch). One could say that because the sensor is smaller, it is much easier to integrate it anywhere within the device. Resulting in flexibility and thus form factor benefits for the end device – one of them being size of the medical device.

Therefore all portable medical devices that require measuring air flow / gas flow benefit from the SDP3x sensor. The products range from traditional portable devices like oxygen concentrators and oxygen conservers to small portable CPAP devices. Today these applications already use our second generation products.

New applications like spirometers and drug delivery devices that do not use sophisticated sensor technology yet, will be enabled by the SDP3x to gather health related data and connected to the internet of things for processing and diagnosis.

Can you please outline how the SDP3x sensor could be used for smart technologies such as smart inhalers?

Today inhalers are not yet able to measure inspiration and track this information on the device or in the cloud. In the future this can help to increase patient compliance and make therapy more efficient by reminding and guiding the patient during the drug intake. Also it allows doctors to access patient records and provides the basis for big data approaches.

Could the SDP3x sensor also be used to measure the flow of gases for anaesthesia, oxygen etc.?

Absolutely, the core technology is the same as for the other flow sensor solutions that Sensirion offers for these applications. The SDP3x sensor can be used in all applications where customers previously used the second generation differential pressure sensors (SDP600 series).

Both generations feature excellent accuracy and long-term stability, have no zero-point drift and are ideal for the measurement of mass flow in a bypass configuration (we describe the details of this method in our whitepaper on “Efficient Gas Flow Measurements in Bypass” available on our website).

In many intensive care devices size is not a major requirement but it is still nice to make these devices smaller and lighter. Sensirion also offers specialized flow sensors for those applications.

Why was integrating sensors previously difficult in home care devices for ventilation and how do you hope the SDP3 sensor will overcome these issues?

Cost is nowadays an important topic in medical devices. The previous generation of differential pressure sensors required a manual placement on the PCB. The SDP3x sensor is delivered in tape and reel and medical device manufacturers can use automated pick and place processes to reduce their cost for mounting the sensors significantly compared to a manual mounting process.

Integration into a device itself is not easier with the SDP3x sensor, depending on the requirements it might bring its own challenges due to the small size.

What do you think the future holds for differential pressure sensors? Will they be even smaller or more advanced in other ways?

This is an interesting question. The SDP3x is a revolutionary breakthrough in size and we expect that we and our customers will still be absorbing the new exciting possibilities and sometimes also challenges that come with this size for the coming years. The chip platform on which the SDP3x based is very versatile and allows Sensirion to adapt to new customer requirements.

We still see a lot of room for innovation and improvement in helping our customer to integrate a differential pressure sensor into their system. A good example is the differential pressure sensor in bypass configuration, which is a perfect solution for cost effective high volume applications where a gas flow needs to be accurately measured in a small space.

In the next months we will continue to present solutions, tools and documentation that help customers to design in our differential pressure sensors even easier and faster. We published a technical white paper already: “Efficient Gas Flow Measurements in Bypass”

Making the differential pressure sensors even smaller might not bring any more advantages as the integration and connection of even smaller sensors then might be too much of an additional integration effort. Even today there might be customers that prefer the SDP600 series, because it allows manual handling in low volume projects.

What is Sensirion’s vision for the future?

Sensirion’s products are already part of medical devices that are used by more than 10 million patients per day, making us the market leader in this field.

Although patients do not know that Sensirion is inside their medical device, those patients benefit from increased patient comfort, more precise therapy, high reliability and finally overall lower healthcare costs.

Our vision for the future is to improve the life of 100 million patients worldwide with Sensirion sensor solutions integrated into medical devices and healthcare related applications. For my colleagues and for me personally it is important that Sensirion can keep creating innovations again and again.

Where can readers find more information?

Please find more information about the world’s smallest differential pressure and flow sensor on our website https://www.sensirion.com/ and further information about our different generations of differential pressure sensors on https://www.sensirion.com/. For further information, please contact me by email ([email protected]).

About Daniel Träutlein

Dr. Daniel Träutlein is Sales Director Medical at Sensirion. In this position, Daniel Träutlein manages Sensirion’s medical business and oversees the world-wide expansion of sensors and sensor solutions for the measurement and control of gas flow, differential pressure, liquid flow, humidity and temperature into medical devices. Furthermore, he is responsible for several OEM projects. Dr. Daniel Träutlein has a degree in physics and brings with him experience in strategic market development and international project management.