This article shows how the Z-team from Zeus was able to save a client $550,000 a year by coming up with a custom-made catheter manufacturing process.

The Customer Issue

A company that makes medical devices for sale all over the world was having problems with the way their product was recovering after heat shrink during the production of catheters. The Zeus Heat Shrink was compliant with incoming inspection requirements but the product was still showing signs of being too tight recovering over the shaft of the catheter.

This led to the catheter braid (which was underneath the reflowed thermoplastic) being seen at the surface, which caused blisters to appear over the catheter, along its length.

This process of heat shrink recovery and reflow was costing the customer heavily, by causing a loss of about 65% in yield of the production component, causing the production expenses to rise, the final output to decrease, and more inspections to become necessary.

Customer Issues

- Additional Costs

- Diminished Yields

- Frequent Inspections

Analysis

In order to resolve this issue, the Z-team from Zeus made a visit to the customer. They did a root cause analysis focusing on the process of heat shrink recovery, with the help of Six Sigma tools. This showed that the solution was to change the specified recovered and expanded inside diameter (ID) of the heat shrink.

As an immediate fix, Zeus increased the level of inspection on its side and arranged that all materials shipped should comply with these new specifications.

At the same time, Zeus engineers were striving to improve in-house process capabilities for the heat shrink, so that it could conform to the new dimensions. The performance of organized validations brought up the conclusion by both Zeus and the OEM that the best way to increase the yield and keep it above 95% was to enlarge the heat shrink’s recovered ID size and decrease the expanded ID size.

Results

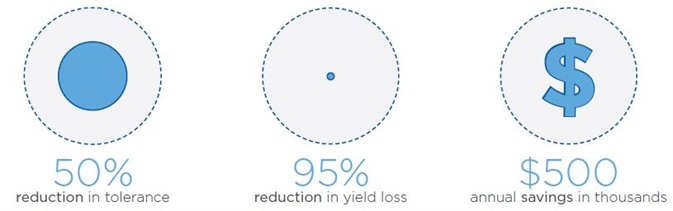

When these measures were adopted the tolerance went down by 50% and the yield loss was reduced by 95%. This was responsible for a cost savings of more than $550 000. The new dimensions specified brought the shrink ratio down so that it performed optimally within this window, allowing it to fit the requirements for catheter assembly very accurately.

The Z-team thus partnered with the client to reduce the loss in yield to below 3%, while lowering the number of required inspections and time required for sorting, which in turn reduced the level of inventory for this part.

Customer Results

- Performance Gain

- Loss Reduction

- Lower Inspection Time

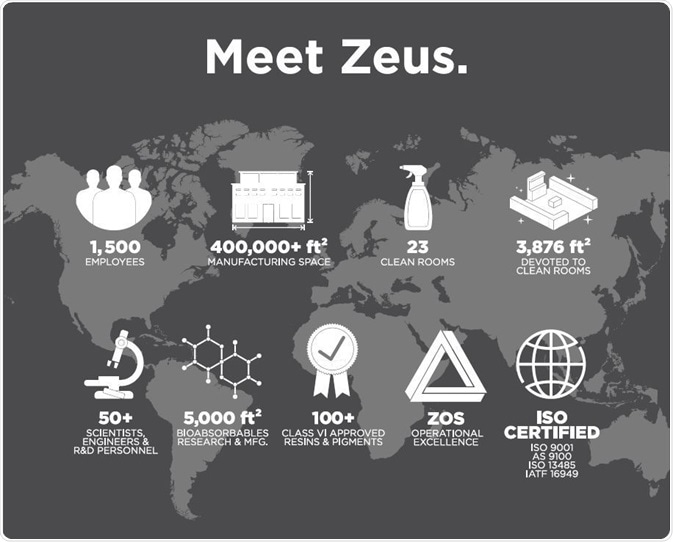

About Zeus Inc.

Zeus were among the first to work in the arena of minimally invasive techniques for revolutionary procedures such as neuromodulation. Their PEEK drawn fiber offers a non-metallic replacement for stainless steel. And when a major aircraft manufacturer needed an immediate design change on a harness assembly, Zeus delivered in record time.

Zeus has vast experience in medicine, aerospace, energy exploration, automotive, fiber optics and more allowing you to leap past “can’t” and into “how”.

What makes them different is that they think differently. Even though they’re the world’s leading expert in polymer tubing, they’re much more than a polymer tubing company. Zeus solves problems and anticipates innovation. Zeus are in the business of changing lives.

History of Zeus Inc

Frank P. Tourville, Sr. worked in the polymer extrusion industry for ten years before creating Zeus from a desire to “do it better.” While Zeus quickly established itself as a world leader providing high-performance polymer extrusions and solutions, their rapid, sustained growth is rooted in a commitment to improving industries and lives.

Zeus is Everywhere You Are

Zeus touches just about every major industry in the world. Their products make everyday life better, faster, safer. You’ll find Zeus technology in your backyard grill and automobile. You’ll find them in the aircraft taking you where you need to go and the hand of the surgeon saving your life. Zeus' research facilities are surpassed only by the enthusiasm and commitment of our people.

Why Choose Zeus As An Innovation Partner?

When your product and reputation are on the line, you want the best. No other company in the world delivers the consistency, dependability and unrivaled innovation of Zeus.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.