Sponsored Content by ScitegrityReviewed by Olivia FrostNov 13 2023

On Tuesday, December 8, 2020, at around 10 p.m. EST, an explosion occurred at Optima Chemical LLC in Belle, WV. This unfortunate event resulted in one fatality and two injuries, necessitating a shelter-in-place order for community members residing within a two-mile radius of the facility.

Image Credit: Scitegrity

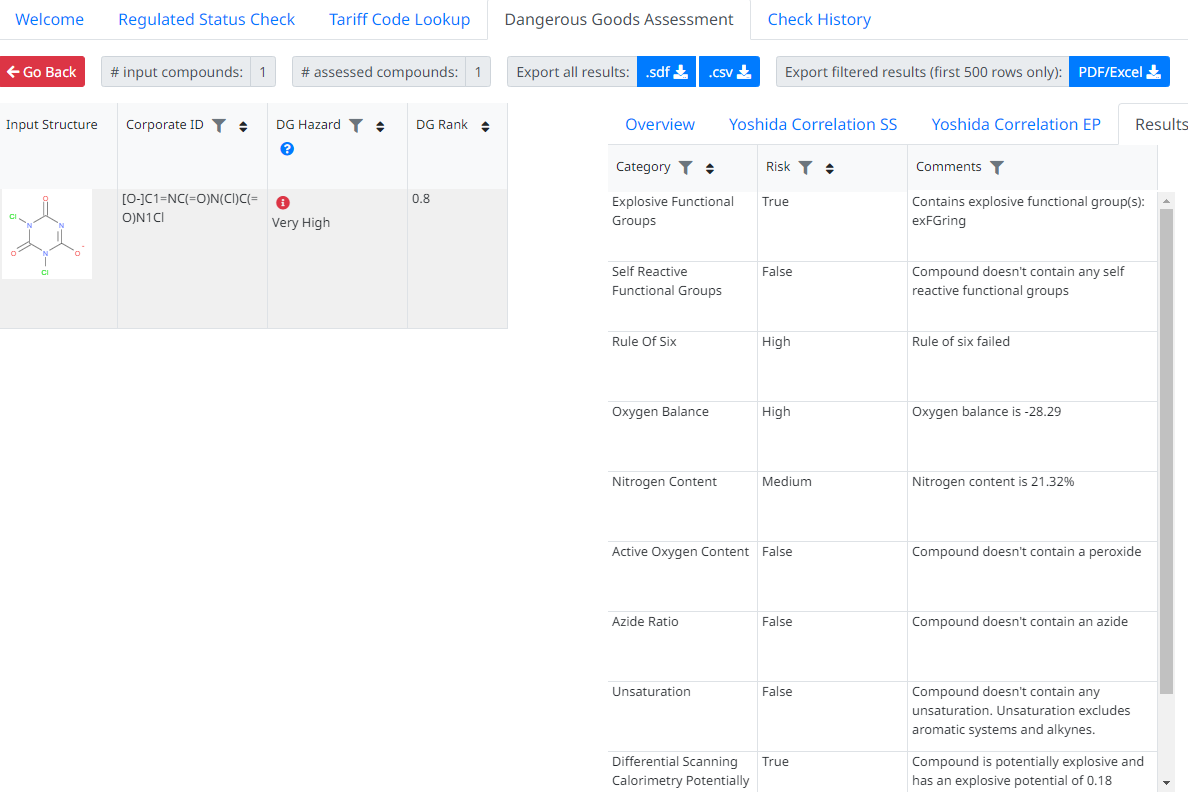

The explosion was triggered by a pressure-rated rotary double-cone dryer containing a chlorinated isocyanurate compound known as sodium dichloroisocyanurate dihydrate (NaDCC dihydrate), marketed under the trade name CDB-56®. This led to a fire and the release of toxic chlorine at Optima Belle LLC in Belle, West Virginia.

The estimated property damage incurred by Optima Belle due to this incident amounts to $33.1 million. In response to this incident, the United States Chemical Safety Board has recently issued a report, which includes several recommendations.

One of these recommendations pertains to adopting an assessment process known as the O.R.E.O.S method.

This method evaluates whether a chemical poses a risk before being used in scaling-up or synthesis processes. O.R.E.O.S was initially detailed in a paper published in 2021 by Vertex Pharmaceuticals and Sperry et al.

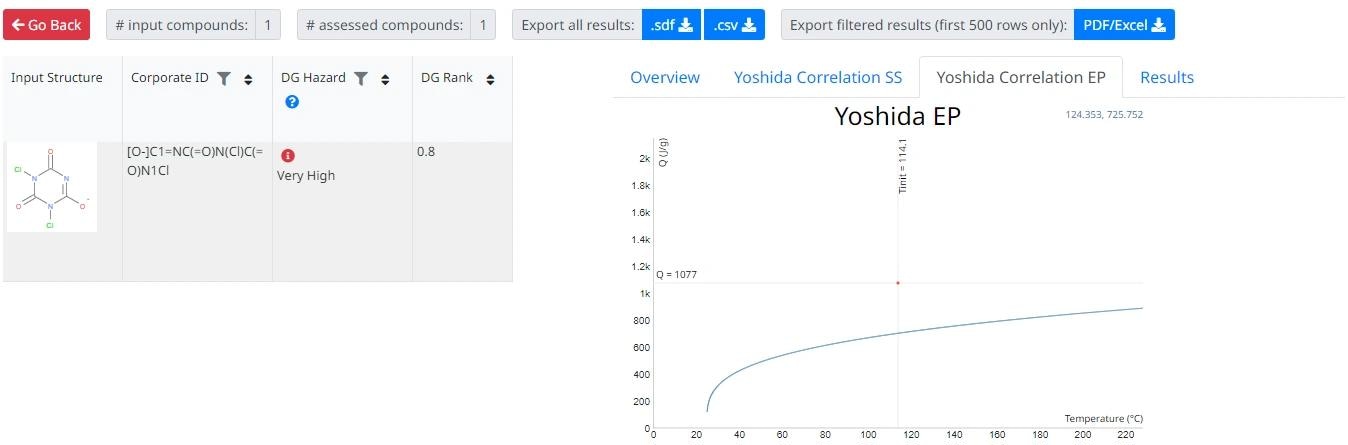

This approach involves an in-depth assessment of various chemical characteristics, including explosive functional groups, oxygen balance, adherence to the rule of 6, onset temperatures, Yoshida correlations, and scale.

Scitegrity's DG Assessor tool incorporates this methodology, and it is believed to be the only commercially available tool capable of doing so. Had it been accessible in 2020, it would have promptly and accurately identified the chemicals involved as being at high risk of explosion, as illustrated below.

Image Credit: Scitegrity

Image Credit: Scitegrity

The provided example includes the results (Tinit and energy released) from a Differential Scanning Calorimetry (DSC) instrument, enabling DG Assessor to calculate Yoshida correlations and take them into account.

However, DSC data is only sometimes readily available. Even without this data, the DG Assessor can classify this as a high-risk chemical based solely on the chemical structure.

This tool was developed in collaboration with the safety and process chemistry groups of a major pharmaceutical company.

Its algorithms and checks also assist in meeting the requirements and assessments outlined in the UN Manual of Tests and Criteria for evaluating chemicals for potential safety concerns before handling or shipping, as well as the ECHA CLP assessment procedures (section 2.1.4) concerning "Screening procedures and waiving of testing" for chemicals.

About Scitegrity

Want to know if your chemical is controlled, regulated, has the potential for abuse or just need a tariff code?

The regulatory and chemistry experts of Scitegrity encode chemical regulations from around the world allowing you to simply answer these questions and more by drawing or looking up a chemical structure.

We make regulatory compliance a simple, robust, background process. Join with 5 of the worlds top 10 pharma, chemical suppliers, regulators, CROs, forensics labs and more who trust and rely on our solutions.

Scitegrity was founded in 2011 by ex-Pfizer and Roche chemists and data scientists with the goal of making compliance to chemical regulations are far more robust, accurate and automatic.

By automatically checking all the chemicals an organisation has at the structure level, it allows enterprise wide automatic compliance checks against hundreds of regulations globally, even for novel and proprietary chemical collection running into millions of chemicals.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.