Jan 16 2007

For over 25 years CSMA have provided analytical solutions to the medical device sector.

For over 25 years CSMA have provided analytical solutions to the medical device sector.

Primarily concentrating on chemical characterisation, the areas benefiting from the analysis include:

- Coating integrity determination

- Contamination analysis and quantification

- Biocompatibility assessment

- Auditing medical device production

To satisfy a growing industry demand CSMA has now developed a unique range of physical testing and analysis. The medical coating analysis suite includes:

1. Wear Resistance

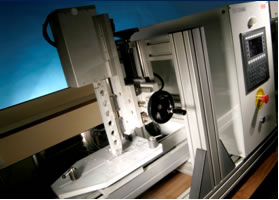

An automated wear element simulates the effect of component use over time. The computer controlled instrument enables the accurate repeatability of test parameters and provides detailed statistical analysis.

|

|

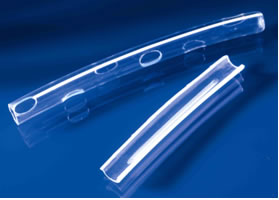

Examples of Catheter Tubing - One Showing a Wear Scar |

|

|

Wear and Friction Test Equipment |

The extent of wear is determined in terms of overall loss of material. Additionally, the worn surface can be compared with a reference surface in terms of surface topography or surface disruption.

2. Frictional Properties

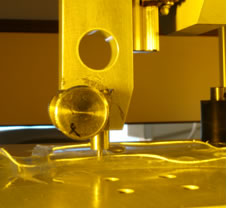

The frictional properties of the surface are quantified. This can be performed under dry conditions or using a wetting agent defined by the client (water, saline solution, blood simulant etc.

|

|

Friction Test Measurement |

3. Surface Topography

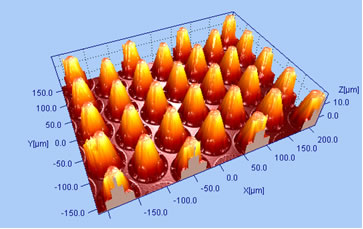

CSMA’s 3DP (3D non contact surface profiling) enables fine detail between alternate coating systems to be compared. In addition to tailored quantified data on surface roughness, surface void volume, etc. 3D images and contour maps of the surface features add to the understanding of the coated product. Large spatial areas can be mapped and depth resolutions on the nm scale are achievable.

|

|

3DP of Microlens Array |

3DP has enabled a detailed understanding of coated products in areas such as:

- Coating roughness evaluation. Correlations can be made with the frictional properties and effect on the host during insertion.

- Surface void volume determination can be performed on base substrates to indicate the likely uptake of coating materials.

- Surface topography can be scrutinised for surface abnormalities such as burrs, spikes, bare patches, etc.

4. Coating Thickness and Integrity

Scanning Electron Microscopy (SEM) is used to monitor coating thickness across the device, catheter, etc. The integrity of the coating bond interface can also be interrogated. Localised delamination, bubbling and contamination are issues typically investigated.

5. Contact Angle (Wettability; Hydrophilicity)

A Wilhemy plate method is used to accurately determine the contact angle in water or solvent of choice. The test can be performed dynamically and both advancing and receding angles can be determined.

|

|

Contact Angle Test Equipment |

Click here for more information from CSMA.