Nov 16 2016

Market leaders in temperature controlled microscopy and established manufacturers of advanced freeze drying microscopes, Linkam Scientific Instruments, announce the launch of the FDVS platform, a lyophilisation system to replicate large scale freeze drying processes.

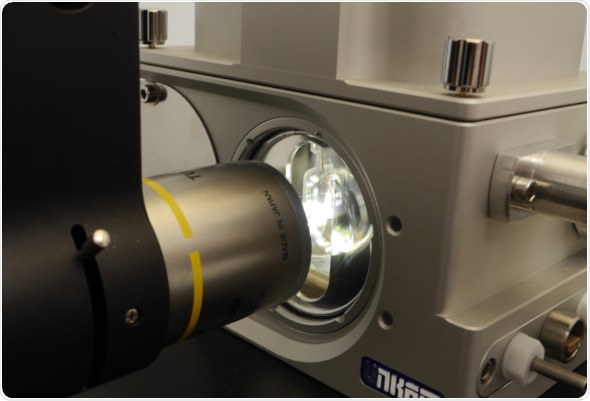

An optical microscope enables the viewing of vials in Linkam’s new freeze drying vial system, FDVS, to replicate lyophilisation in large scale freeze drying processes

Replicating large scale industrial freeze drying processes as smaller test runs is an effective way to save time, cut costs and perfect the technicalities of an operation run. With this in mind, Linkam engineers have created the new Freeze Drying Vial System - FDVS.

Building on the experience gained from the FDCS Freeze Drying stage, Linkam launch the FDVS, a chamber system with the capability to house up to seven lyophilisation vials. By incorporating vials, the FDVS works with greater sample volume and uses enough material to better simulate large scale industrial processes while minimising sample wastage.

While it saves time and money, the unit has been designed to save space. It is supplied on an ergonomically-designed table housing the controller units with the stage, optical microscope and imaging system mounted on top. By keeping the system compact, it conserves vital benchtop space.

The system was built with the scientific process in mind and as such comes with several specialised components which are essential to the freeze drying process. The optical system can be controlled in the X, Y and Z axes with a 10x darkfield lens mounted in line with the freeze drying stage. With this specially designed optical set-up, monitoring and tracking the position of the sublimation interface can be done simply and efficiently. Real time imaging allows the user to see structural changes in their samples as lyophilisation occurs in the vials. A built-in cold trap removes any excess moisture.

The system is fitted with two vacuum sensors, a capacitive and a Pirani-type sensor, which allow accurate measurement throughout the drying process and detection of the end point of primary drying. The top of the stage also features a vial stopper which allows the open vials to be closed once the freeze drying process is complete.

With the FDVS system, the new Optical DSC and TASC Image Processing module, Linkam now provides a range of Thermal Analysis tools to meet the needs of developing freeze drying protocols within the pharmaceutical industry.

Source: http://www.linkam.co.uk/