Throughout the United States, the cases of the coronavirus disease 2019 (COVID-19) have surged in almost every state, largely as a result of the emergence of more neutralization-resistant variants of the severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2). A new study published on the preprint server medRxiv* discusses the measures that should be taken to mitigate the risk of COVID-19 among food industry workers.

To this end, the researchers found that if proper precautions are taken, food industry professionals can keep themselves safe against COVID-19, even as new variants arise.

Study: Ongoing mitigation strategies and further needs of the United States food industry to control COVID-19 in the work environment. Image Credit: SritanaN / Shutterstock.com

Study: Ongoing mitigation strategies and further needs of the United States food industry to control COVID-19 in the work environment. Image Credit: SritanaN / Shutterstock.com

*Important notice: medRxiv publishes preliminary scientific reports that are not peer-reviewed and, therefore, should not be regarded as conclusive, guide clinical practice/health-related behavior, or treated as established information.

*Important notice: medRxiv publishes preliminary scientific reports that are not peer-reviewed and, therefore, should not be regarded as conclusive, guide clinical practice/health-related behavior, or treated as established information.

Background

The food industry in the United States is critical to nutritional security for the American population. Early on in the COVID-19 pandemic, the supply chain was disrupted, which lead to both labor and market shortages in the market, reduced production, and poor productivity due to increased absenteeism.

The impact of COVID-19 on the food sector led to the consideration and application of numerous public health interventions to protect these workers. Nonetheless, COVID-19 outbreaks across the U.S. food industries led to over 90,000 infections and 450 deaths between April 2020 to July 2021.

“Food and agriculture workers are amongst the occupations most severely affected by excess deaths due to COVID-19.”

This makes it necessary to understand the needs of this sector, and the responses necessary to meet them.

Both the United States Centers for Disease Control and Prevention (CDC) and the Occupational Safety and Health Administration (OSHA) have been involved in implementing non-pharmaceutical guidelines such as biosafety norms, social distancing and face masks, as well as workplace surveillance, in their efforts to limit the spread of SARS-CoV-2. However, data on compliance with these guidelines is scarce, and relevant studies are both early and limited in their scope.

Study aims

The current study aimed to define the needs of the United States food industry in COVID-19 mitigation and how current strategies were being applied in the workplace. To do this, the researchers designed an assessment survey that was administered between January and April 2021.

What were the findings?

A total of 79 useful responses were obtained from the survey. Of these 79 participants, 48% were from the dairy industry and 22% were from fresh produce. The remaining 28% of participants worked in other food industry sectors including those that produce chocolate, frozen food, wine, and cereals. Only two of the responses were obtained from beef/pork industry sources, whereas three participants reported working with all four primary food industry sectors. Notably, no participants reported working in the poultry industry.

A majority of the survey responses were provided by food safety and quality directors, managers of the facility, and a few executives. Approximately 85% of the survey participants indicated that their sector had been significantly impacted by COVID-19. The most common ways in which COVID-19 impacted these sectors include:

- Changes in the staff pattern

- Protective guidelines implemented at work

- Remote work for all but essential workers

- Reduced production.

Most participants described their sector plants as employing up to 250 persons. The responses showed that up to 15% of staff could be reduced without impacting production capacity over a week. One in ten of these plants provided temporary housing or transport to employees.

Labor availability

To maintain the stability of their production processes in the event of a COVID-19 outbreak, 75% of the participants claimed to favor extending work hours for the healthy remaining workers. Comparatively, 61% said they would shift people around to make up for large personnel gaps.

Over the long term, 72% of participants agreed that mechanization was an ideal long-term solution to maintain production if COVID-19 led to chronic shortages of people in the future. Another suggestion was that the employee and production schedules should be adjusted to keep production high during these possible situations.

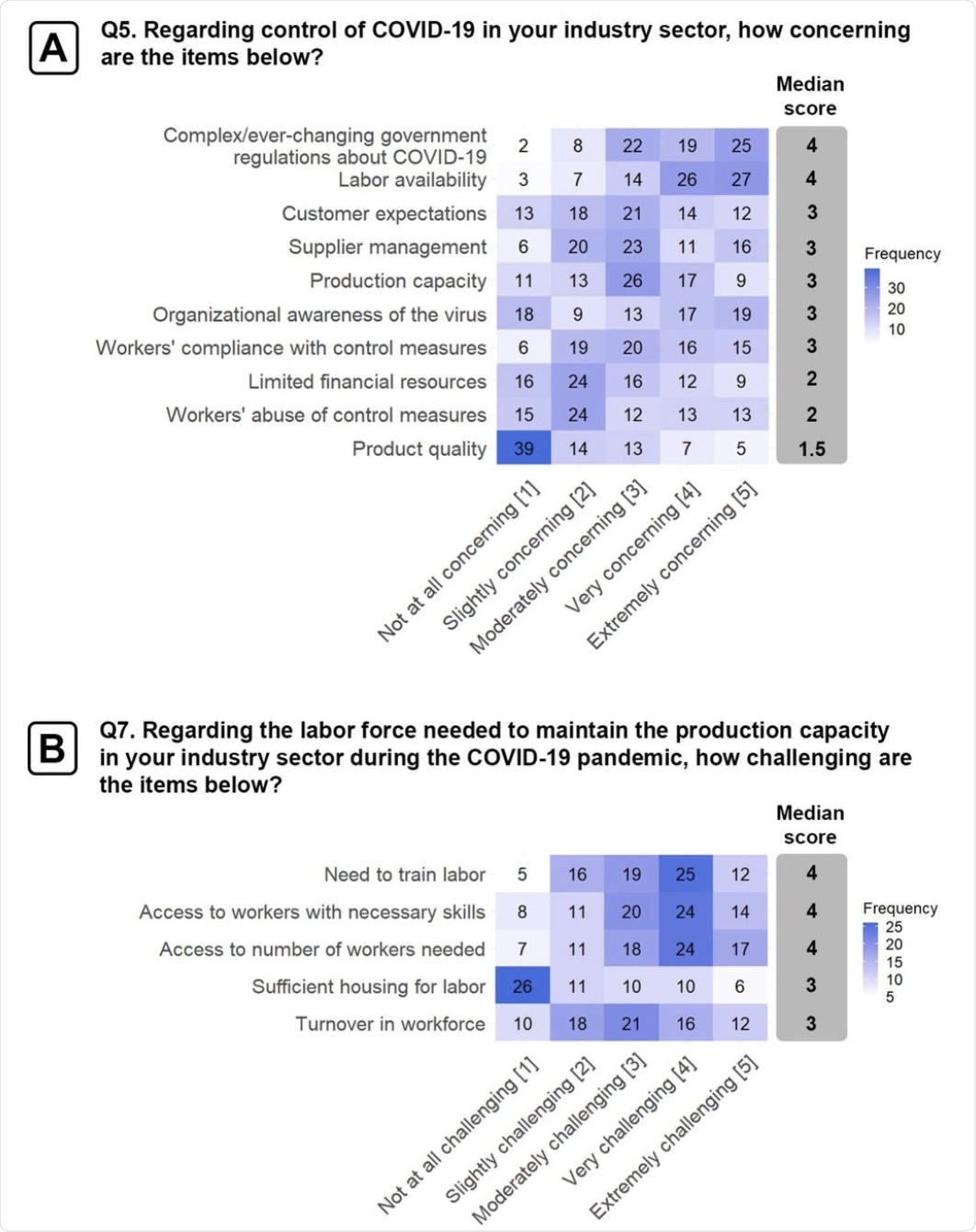

Many participants indicated that both the availability of labor, as well as the complex and always-changing government regulations were very concerning. These concerns differed greatly from those surrounding product quality, lack of backup capital, and the potential for workers to misuse protective guidelines, all of which were only slightly concerning for most survey participants.

Survey participants reported the compelling need to train or hire workers to ensure skilled labor, in addition to having a worker reserve. The fact that managerial staff was cut back in favor of expanding production capacity left many workers feeling “stretched thin” and “overwhelmed,” due to the lack of operational supervisors to ensure things were running smoothly and efficiently.

Specialized jobs were most likely to be shut down, along with engineering and maintenance crews, as well as sanitation and cleaning workers.

Heatmaps representing responses to 5-point scale Likert questions regarding [A] concerns about COVID-19 control and [B] challenges to maintain production. These Likert questions were included in part 1 of the needs assessment survey asking general questions about a participant’s industry sector. For each item within a Likert question, a median shown to the right of the heatmap was calculated from the interval values (1-5), assigned to answers ranging from “Not at all concerning” to “Extremely concerning” [A] and “Not at all challenging” to “Extremely challenging” [B].

Heatmaps representing responses to 5-point scale Likert questions regarding [A] concerns about COVID-19 control and [B] challenges to maintain production. These Likert questions were included in part 1 of the needs assessment survey asking general questions about a participant’s industry sector. For each item within a Likert question, a median shown to the right of the heatmap was calculated from the interval values (1-5), assigned to answers ranging from “Not at all concerning” to “Extremely concerning” [A] and “Not at all challenging” to “Extremely challenging” [B].

Funding and changing rules

Small businesses obviously had greater fears of running out of money, as did fresh produce industries, while the dairy sector was spared. Supplier management was also a significant concern for small businesses.

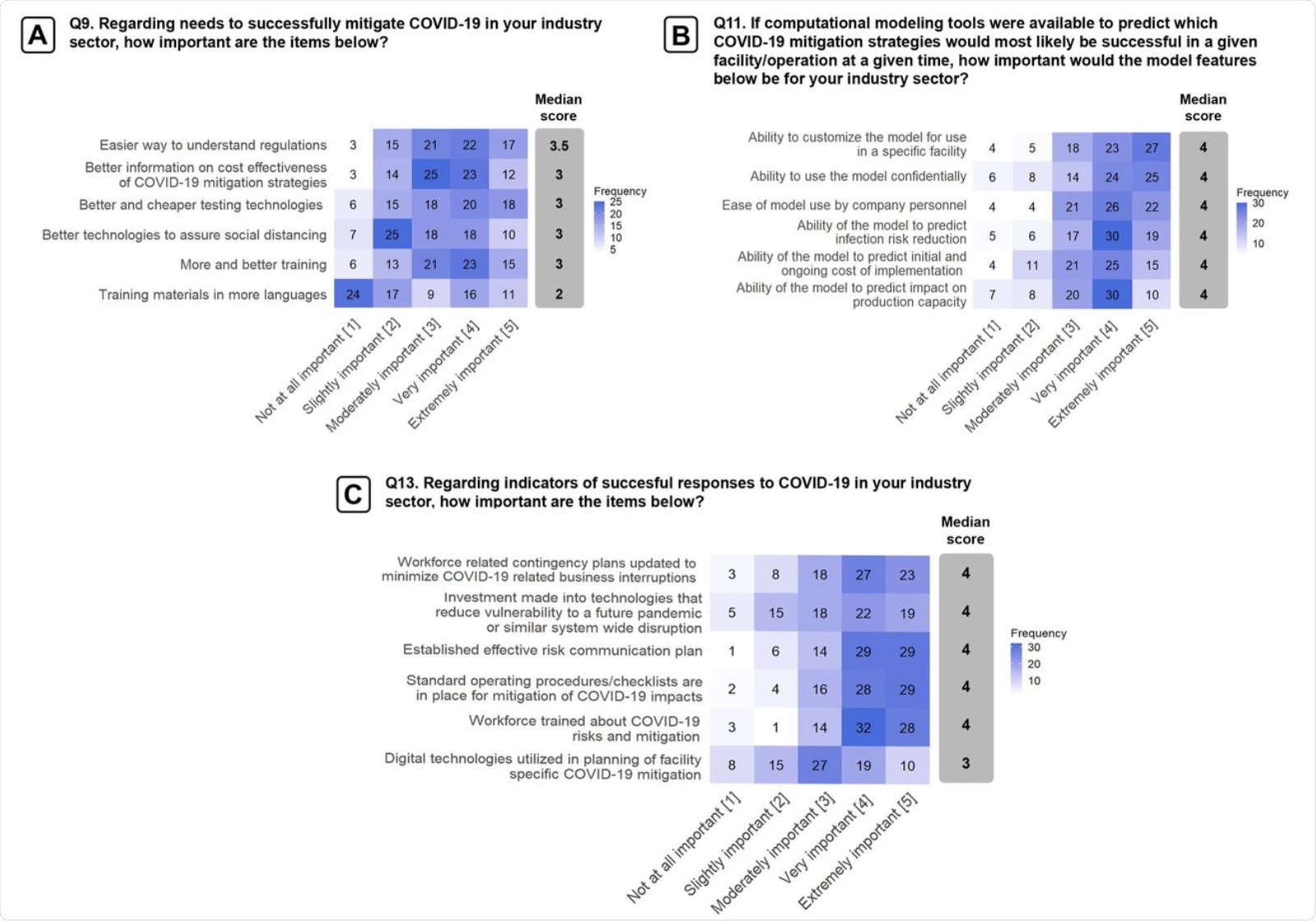

Ever-changing government directives led to frustration with having to spend much time dealing with the rules rather than ensuring pandemic-safe operations. The participants felt that making regulations easy to understand were the single most important step required to reduce the risk of COVID-19 in the industry.

Community activities were thought to be the most likely sources of COVID-19 introduction into the plant. Although indoor common areas were perceived as a problem area in medium-sized companies, this sentiment was not shared among small or large companies.

Other measures

Most participants reported that their plant was using mitigation measures such as those mentioned above, at least in part, along with staggered shifts and breaks. The least implemented measures included reducing staff and forming employee cohorts. Moreover, social distancing strategies were less common in smaller plants.

Hand hygiene, face shielding, air cleaning, temperature screening, and quarantine were among the most common strategies for biosafety. Face coverings were more common among dairy and “Other” sectors, and less among small businesses. Increasing ventilation rates were introduced in less than half the cases.

The barriers to the implementation of either of these categories of protective measures included infrastructural constraints, limited funding, inadequate supplies, the need for productivity, and union demands, as well as a feeling that the measures were unnecessary.

Monitoring strategies varied among facilities, the most common being temperature screening, quarantine, post-recovery return to work guidelines, and contact tracing. Testing and isolation were less commonly used.

Heatmaps representing responses to 5-point scale Likert questions regarding the [A] needs to successfully mitigate COVID-19, [B] preferred features in predictive models, and [C] indicators of a successful response against COVID-19. These questions were included in part 1 of the needs assessment survey asking general questions about a participant’s industry sector. For each item within a Likert question, a median shown to the right of the heatmap was calculated from the interval values (1-5), assigned to answers ranging from “Not at all important” to “Extremely important”.

Heatmaps representing responses to 5-point scale Likert questions regarding the [A] needs to successfully mitigate COVID-19, [B] preferred features in predictive models, and [C] indicators of a successful response against COVID-19. These questions were included in part 1 of the needs assessment survey asking general questions about a participant’s industry sector. For each item within a Likert question, a median shown to the right of the heatmap was calculated from the interval values (1-5), assigned to answers ranging from “Not at all important” to “Extremely important”.

What are the implications?

The study findings suggest that most of the surveyed facilities used mitigation strategies, excluding those that led to reduced productivity, were too expensive, or whose cost-effectiveness was inadequately detailed. The size of the business affected decisions on these strategies.

The widespread partial or full adoption of these strategies owes much to the funding provided by the federal government to help businesses recover from the pandemic. This did not, however, fully allay the concerns of many businesses about the funds required to, for instance, put in physical barriers to separate employees in the workplace.

This suggests that further financial aid will be needed to accomplish such measures. Additionally, in the future, companies may be required to plan for preparedness strategies.

The awareness and adoption of such measures were fairly common. The implementation of detailed guidelines for the execution of these measures also indicates the ability to put them in place rapidly in future situations demanding similar controls.

Laying off employees does not appear to be an attractive measure as it reduces productivity, as well as creates job insecurity and a higher workload for the remaining employees. Coupled with reduced managerial staff, this was found to increase the likelihood of greater employee stress.

Taken together, while downsizing may be a viable strategy for pandemic mitigation, other steps must be taken to support the mental health of the employees and maintain production.

Shortages in PPE and real-life assessments of the viability of measures such as face masks in hot and humid environments such as dairy farms are alike necessary for successful mitigation strategies.

“Altogether, our findings suggest that sectors of the food industry represented in the survey are prepared to implement biosafety strategies in the event of a new variant of the SARS-CoV-2 beta-coronavirus, future COVID-19 pandemics or similar disasters caused by airborne-transmitted pathogens.”

Engineering controls such as air filters required more time, money, and planning, thus indicating that many businesses were not equipped to accommodate these interventions. Surveillance measures were also difficult to implement without sufficient funding, as they require ongoing investment. Temperature screening was especially unsatisfactory, the scientists found.

Both medium and large companies were more likely to implement mitigation strategies, as was the fresh produce sector. Thus, small businesses require the development of cost-effective and flexible strategies to maintain their production at high rates while dealing with the pandemic’s demands. Dairy operations were often performed outdoors, which may account for these workers' lower use of PPE.

Improved digital technologies will help train workers as well as evaluate the impact of COVID-19-like disruptions. Some potential technologies that could be used for these purposes include modeling tools and data collection/management software; however, these measures can be costly.

“Future collaborations between the US food industry and federal and state agencies to establish contingency plans and define appropriate training, as well as the development of food industry-directed technologies will be crucial to building resilience against future COVID-19-related and similar disturbances.”

*Important notice: medRxiv publishes preliminary scientific reports that are not peer-reviewed and, therefore, should not be regarded as conclusive, guide clinical practice/health-related behavior, or treated as established information.

*Important notice: medRxiv publishes preliminary scientific reports that are not peer-reviewed and, therefore, should not be regarded as conclusive, guide clinical practice/health-related behavior, or treated as established information.