Delivering informative structural data and direct quantification, the Fourier PAT benchtop NMR minimizes tedious calibrations while improving understanding and control of (bio) processes and lowering risks and costs. Powered by the new synTQ by Optimal NMR adapter, the device introduces the Bruker Fourier 80 to the field of Process Analytical Technology.

Fourier PAT offers a complete solution for online Nuclear Magnetic Resonance (NMR) monitoring and process control. It facilitates real-time monitoring of chemical reactions under true process conditions.

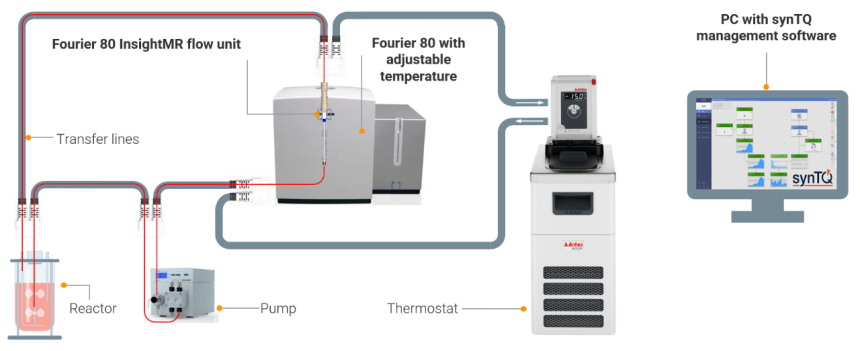

With more than 200 adapters in its portfolio, synTQ seamlessly integrates multiple systems in the lab, from reactors and sensors to the full Fourier RxnLab suite. Complementary analytical tools (IR, Raman, etc.) and data processing software help to create a continuous loop of optimization and control. The result is a clearer, faster, and safer pathway to advancing research.

The Fourier PAT is optimized for batch and flow chemistry processes in pharmaceutical, biochemical, and chemical applications. It is also the ideal solution for digital labs and advanced manufacturing scenarios, including the Production On Demand concept.

Image Credit: Bruker BioSpin Group

Technical features

- The device has a durable flow unit, based on the proven InsightMR design, withstanding pressures of up to 10 bar

- It provides complete temperature control from 25 to 60 °C for the sample and transfer lines, ensuring thermal stability from the vessel to the magnet

- Automated control of the pump and thermostat is managed through synTQ

- Dynamic software interface enabling real-time reaction adjustments through synTQ optimization

- Seamless data transfer from acquisition to analysis, with automatic visualization of NMR and complementary analytical data in synTQ for advanced multivariate analysis

Benefits

- By using real-time NMR analysis in a PAT environment, users can increase the reaction understanding and decrease process optimization time in chemistry

- The system can identify and quantify reaction components, such as metabolites in bioproduction media, in real-time

- On-the-fly quantitative build-up curves with NMR capability for calibrating other analytical techniques (IR, Raman, LC)

- Determination of critical process parameters in both batch and flow chemistry applications

- Real-time multivariate data orchestration delivering unprecedented process insights

- Compact footprint, purpose-built for routine R&D and pilot plant environments

- Comprehensive structural information for reagents, intermediates, products, and byproducts

- Real-time monitoring of conversion, in situ reaction yield, and reaction kinetics